The primary application of PTFE envelope gaskets is for sealing flange connections that demand high chemical resistance, especially when used with fragile or reactive flange materials. They are most commonly found on enamel or glass-lined equipment, plastic piping systems, and in applications where preventing product contamination is critical.

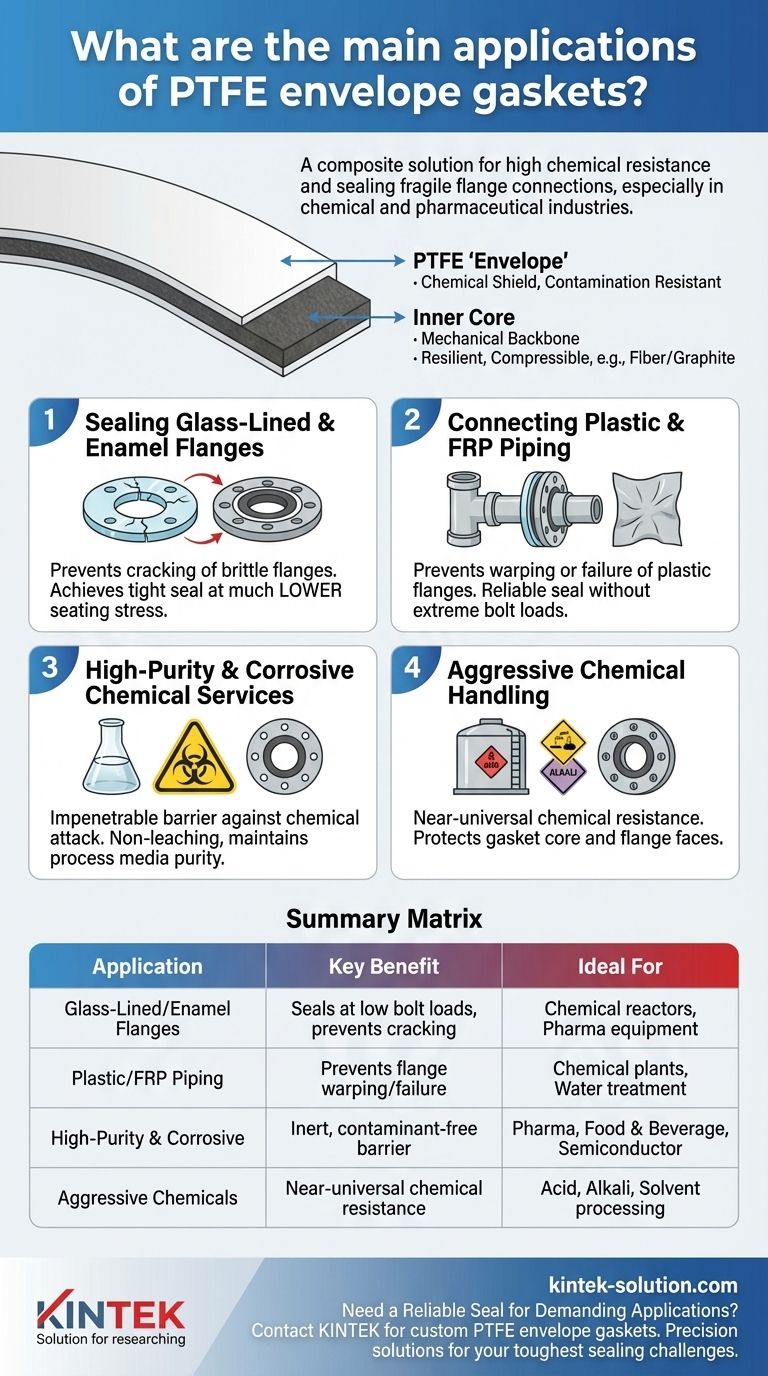

A PTFE envelope gasket is a composite solution, designed to provide the exceptional chemical inertness of solid PTFE while overcoming its mechanical limitations. By encasing a resilient core material in a thin PTFE shell, it creates a chemically resistant seal that works effectively at lower bolt loads, protecting fragile flanges from damage.

Why an Envelope Design? The Best of Both Worlds

To understand the applications, you must first understand the gasket's construction. It isn't a solid piece of PTFE; it's a clever combination of two materials, each serving a distinct purpose.

The PTFE "Envelope": Your Chemical Shield

The outer layer, or "envelope," is made from PTFE (Polytetrafluoroethylene). This material is renowned for its near-universal chemical resistance, meaning it will not corrode or react with even the most aggressive media.

This inertness also makes it highly resistant to product contamination, a critical feature in pharmaceutical, food, and high-purity chemical processing.

The Inner Core: The Mechanical Backbone

Solid PTFE is mechanically weak and prone to "creep," or deforming under pressure over time, which can lead to leaks. The envelope gasket solves this by using a different material for its inner core or insert.

This insert, often made of compressed fiber or graphite, provides the mechanical strength and resilience. It allows the gasket to compress, conform to minor flange imperfections, and maintain a consistent sealing force over its lifespan.

Core Applications and Use Cases

The unique two-part construction makes the PTFE envelope gasket a problem-solver for specific, challenging industrial scenarios.

Sealing Glass-Lined and Enamel Flanges

This is the quintessential application. Glass and enamel-lined steel flanges offer excellent corrosion resistance but are extremely brittle. Applying the high bolt torque required for a solid metal gasket would easily crack the lining.

The envelope gasket's softer, more compressible core allows it to achieve a tight seal at a much lower seating stress, protecting the fragile flange surfaces from damage.

Connecting Plastic and FRP Piping

Similar to glass-lined steel, plastic and Fiber-Reinforced Plastic (FRP) piping systems cannot withstand high compressive loads. Overtightening can cause flanges to warp, crack, or fail.

The PTFE envelope gasket provides a reliable seal without requiring the extreme bolt loads that would compromise the integrity of the plastic flange.

High-Purity and Corrosive Chemical Services

In chemical plants, gaskets are constantly exposed to highly corrosive materials. The PTFE envelope provides an impenetrable barrier, protecting both the gasket's inner core and the flange faces themselves from chemical attack.

Because the PTFE does not leach or shed particles, these gaskets ensure the purity of the process media is maintained.

Understanding the Trade-offs and Limitations

While highly effective in its intended applications, the PTFE envelope gasket is not a universal solution. An objective assessment requires understanding its limits.

Risk of Envelope Damage

The PTFE envelope is relatively thin. It can be easily damaged by scratching or mishandling during installation. Any perforation of the envelope creates a direct leak path for corrosive media to attack the inner core, leading to rapid gasket failure.

Temperature Constraints

While PTFE has a good operational temperature range, it has a definitive upper limit. The core material also has its own temperature rating. For very high-temperature services, such as high-pressure steam, a spiral wound or solid metal gasket is typically a more robust choice.

Not for Extreme Mechanical Duty

The primary strength of this gasket is its chemical resistance and ability to seal with low force. In extremely high-pressure systems found in industries like oil and gas, gaskets designed for intense mechanical stress (like ring-type joints) are the appropriate engineering choice.

Making the Right Choice for Your System

Selecting the correct gasket is about matching its specific strengths to your operational goals.

- If your primary focus is sealing fragile flanges (glass, enamel, plastic): The low seating stress required by an envelope gasket makes it the safest and most effective choice to prevent cracking.

- If your primary focus is preventing product contamination or handling aggressive chemicals: The inert PTFE envelope provides a superior barrier, protecting both your process media and your equipment.

- If your primary focus is high-temperature, high-pressure service (e.g., >500°F / 260°C or >600 PSI): You should evaluate other gasket types, such as spiral wound or Kammprofile gaskets, as they are better suited for extreme mechanical stress.

By understanding its unique two-part construction, you can confidently deploy the PTFE envelope gasket as a precise solution for your most demanding chemical sealing challenges.

Summary Table:

| Application | Key Benefit | Ideal For |

|---|---|---|

| Glass-Lined / Enamel Flanges | Seals at low bolt loads to prevent cracking | Chemical reactors, pharmaceutical equipment |

| Plastic / FRP Piping Systems | Prevents warping or failure of plastic flanges | Chemical processing plants, water treatment |

| High-Purity & Corrosive Services | PTFE envelope provides an inert, contaminant-free barrier | Pharmaceutical, food & beverage, semiconductor |

| Aggressive Chemical Handling | Near-universal chemical resistance protects flanges | Acid, alkali, and solvent processing lines |

Need a Reliable Seal for Demanding Applications?

PTFE envelope gaskets are a precision solution for industries where chemical resistance and equipment protection are non-negotiable. At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom envelope gaskets, for the semiconductor, medical, laboratory, and industrial sectors.

We understand that a failed seal can mean costly downtime and contamination. That's why we prioritize precision production and offer custom fabrication—from initial prototypes to high-volume orders—to ensure a perfect fit and reliable performance for your specific flange connections.

Let us help you solve your toughest sealing challenges. Contact our experts today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials