At its core, Polytetrafluoroethylene (PTFE) is a material of extremes. It is renowned for its combination of exceptional properties, including near-total chemical inertness, an extremely wide operating temperature range, outstanding electrical insulation, and one of the lowest coefficients of friction of any known solid material. This unique blend makes it an indispensable problem-solver in demanding engineering applications.

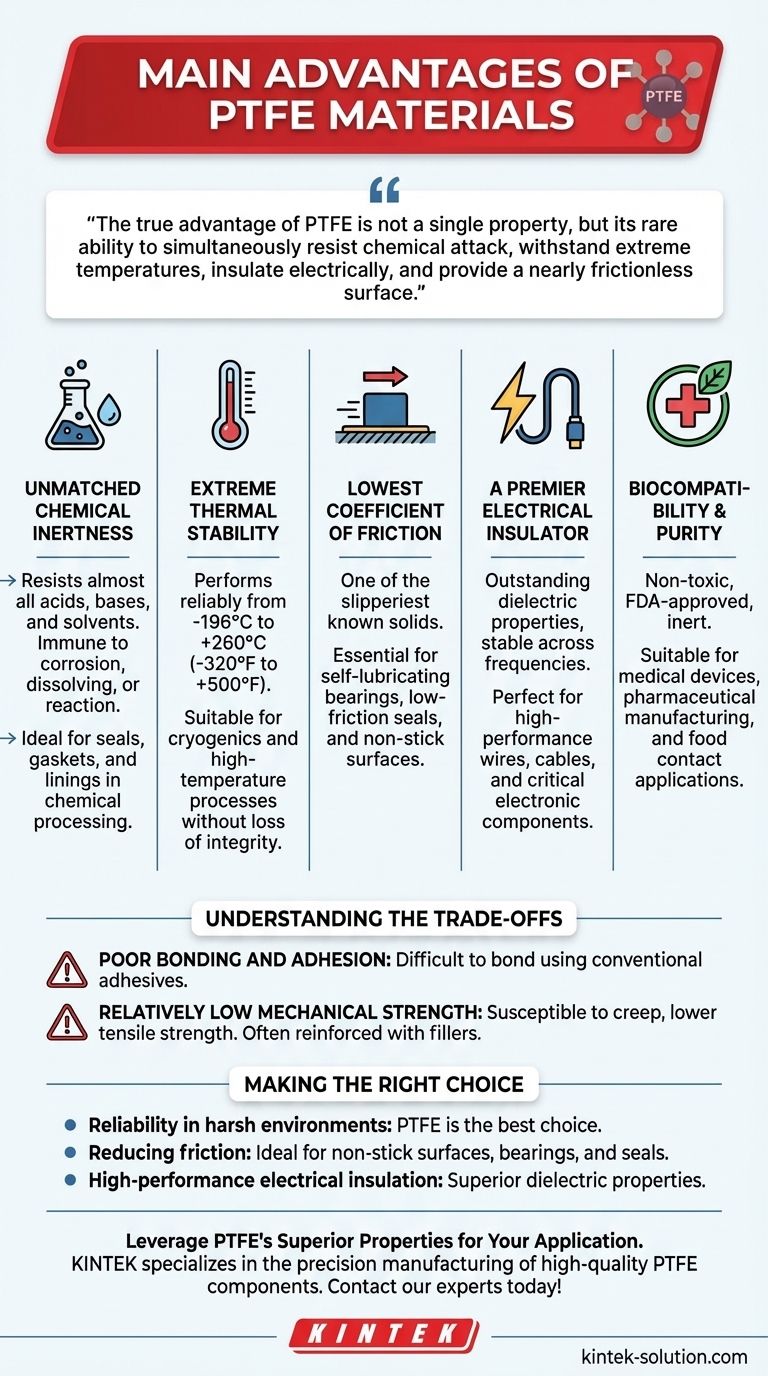

The true advantage of PTFE is not a single property, but its rare ability to simultaneously resist chemical attack, withstand extreme temperatures, insulate electrically, and provide a nearly frictionless surface. This makes it a uniquely versatile material for environments where others would fail.

Why PTFE Excels in Extreme Environments

The fundamental reason for PTFE's widespread use is its incredible resilience. It maintains its integrity under conditions that would degrade or destroy most other polymers and even many metals.

Unmatched Chemical Inertness

PTFE is virtually immune to almost all industrial chemicals, acids, bases, and solvents. This inertness means it will not corrode, dissolve, or react when exposed to highly aggressive substances.

This property is critical for components like seals, gaskets, and linings used in chemical processing, where material failure is not an option.

Extreme Thermal Stability

The material performs reliably across a vast temperature range, typically cited from -196°C to +260°C (-320°F to +500°F).

This allows PTFE to be used in everything from cryogenic applications to high-temperature industrial processes without becoming brittle or losing its structural integrity.

Superior Weather and UV Resistance

Unlike many plastics that degrade with exposure to sunlight and weather, PTFE is highly resistant to UV radiation and environmental aging.

This makes it an excellent choice for long-term outdoor applications, such as architectural membranes or protective coatings.

The Core Mechanical and Electrical Advantages

Beyond its resilience, PTFE's physical properties offer distinct performance benefits that engineers leverage to solve common challenges related to friction and electricity.

The Lowest Coefficient of Friction

PTFE has a remarkably low coefficient of friction, often compared to that of wet ice on wet ice. This makes it one of the "slipperiest" materials in existence.

This characteristic is essential for creating self-lubricating bearings, low-friction seals, and non-stick surfaces for everything from cookware to industrial machinery.

A Premier Electrical Insulator

The material possesses outstanding dielectric properties, meaning it does not conduct electricity and can withstand very high voltages. Its performance is also stable across a wide range of frequencies.

This makes it an ideal insulator for high-performance wires, cables, and critical electronic components, especially in high-frequency applications.

Biocompatible and Pure

PTFE is non-toxic, inert, and FDA-approved for food contact applications. Its high purity and biocompatibility also make it suitable for use in medical devices and pharmaceutical manufacturing.

Understanding the Trade-offs

No material is perfect, and PTFE's unique strengths are accompanied by limitations that are critical to understand for proper application.

Poor Bonding and Adhesion

The same non-stick properties that make PTFE so valuable also make it extremely difficult to bond to other materials using conventional adhesives.

Specialized surface treatments, like chemical etching, are often required to create a bondable surface, adding complexity and cost to the manufacturing process.

Relatively Low Mechanical Strength

While PTFE has good flexural strength, it is a relatively soft material. It is susceptible to creep (slow deformation under a constant load) and has lower tensile strength and wear resistance compared to other engineering plastics.

For high-load structural applications, it is often reinforced with fillers like glass, carbon, or bronze to improve its mechanical properties.

Making the Right Choice for Your Application

Selecting PTFE depends entirely on whether its unique advantages align with the primary demands of your project.

- If your primary focus is reliability in harsh chemical or thermal environments: PTFE is likely the best choice due to its unmatched inertness and stability.

- If your primary focus is reducing friction in moving parts: Its extremely low coefficient of friction makes it ideal for non-stick surfaces, bearings, and seals.

- If your primary focus is high-performance electrical insulation: PTFE's dielectric properties are superior, especially for high-frequency or high-voltage needs.

- If your primary focus is structural integrity under high load or easy bonding: You must account for its limitations by considering filled grades or alternative materials.

Ultimately, understanding both the profound advantages and the practical limitations of PTFE is the key to leveraging its full potential.

Summary Table:

| Key Advantage | Description | Common Applications |

|---|---|---|

| Chemical Inertness | Resists almost all acids, bases, and solvents. | Seals, gaskets, liners in chemical processing. |

| Extreme Temperature Range | Performs from -196°C to +260°C (-320°F to +500°F). | Cryogenic systems, high-temperature processes. |

| Low Coefficient of Friction | One of the slipperiest known solids. | Non-stick surfaces, bearings, low-friction seals. |

| Excellent Electrical Insulation | Superior dielectric properties, stable across frequencies. | High-performance wires, cables, electronic components. |

| Biocompatibility & Purity | Non-toxic, FDA-approved, inert. | Medical devices, pharmaceutical manufacturing, food contact. |

Leverage PTFE's Superior Properties for Your Application

PTFE's unique combination of chemical resistance, thermal stability, and low friction makes it the ideal material for solving complex challenges in the semiconductor, medical, laboratory, and industrial sectors.

KINTEK specializes in the precision manufacturing of high-quality PTFE components. Whether you need standard parts or custom-fabricated solutions—from prototypes to high-volume production—we deliver the reliability and performance your critical applications demand.

Ready to enhance your project with PTFE? Contact our experts today to discuss your specific requirements and discover how our custom fabrication capabilities can provide the perfect solution for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments