At its core, a silicone gasket's primary limitations stem from its poor physical strength and specific chemical vulnerabilities. While it excels in temperature resistance and flexibility, it is not a suitable choice for applications involving high pressure, vacuum, abrasion, or exposure to hydrocarbon-based oils and fuels.

The decision to use a silicone gasket is a trade-off. You gain exceptional performance across a wide temperature range and excellent flexibility, but you sacrifice the mechanical toughness and broad chemical resistance found in other elastomers like Nitrile or Viton.

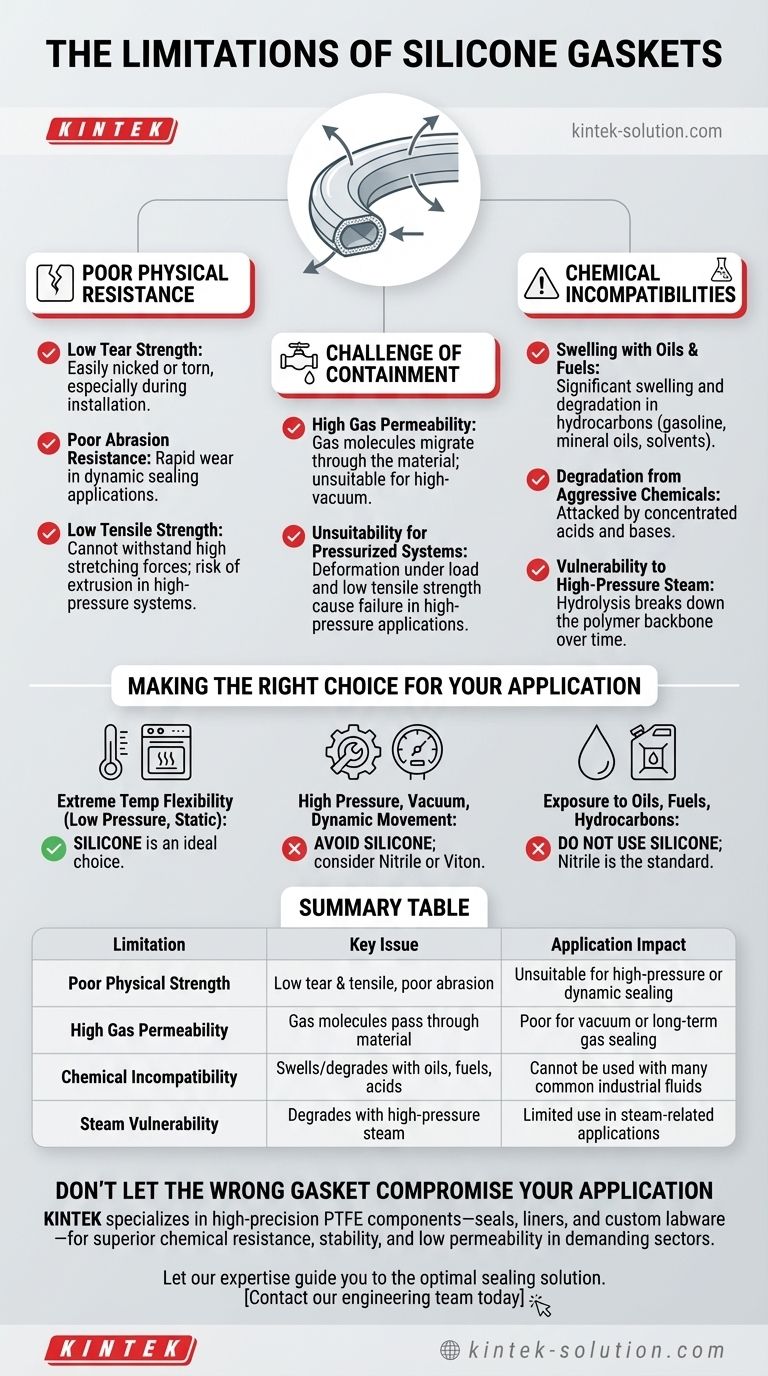

Deconstructing "Poor Physical Resistance"

The most frequently cited weakness of silicone is its lack of physical toughness. This is not a single issue but a combination of several related properties that make it unsuitable for mechanically demanding roles.

Low Tear Strength

Silicone gaskets are relatively easy to nick or tear. This can be a significant issue during installation, where a sharp edge on a housing or a misplaced tool can compromise the seal before it's ever put into service.

Poor Abrasion Resistance

This material is not designed for dynamic sealing applications where parts rub or slide against the gasket. The friction would quickly wear away the material, leading to seal failure. It is best used in static, face-seal applications where it is compressed and left undisturbed.

Low Tensile Strength

Compared to other rubbers, silicone cannot withstand high stretching forces. In a high-pressure system, a gasket made from a low-tensile-strength material can be extruded into the clearance gap between mating parts, causing a leak.

The Challenge of Containment

Beyond physical toughness, silicone's molecular structure presents limitations for containing certain substances, particularly gases and pressurized fluids.

High Gas Permeability

Silicone is naturally more permeable to gases than many other elastomers. This means gas molecules can slowly migrate directly through the material itself. This characteristic makes it a poor choice for high-vacuum applications or for sealing critical gases over long periods.

Unsuitability for Pressurized Systems

The combination of low tensile strength and a tendency to deform under load (compression set) makes standard silicone a risk in high-pressure hydraulic or pneumatic systems. The pressure can force the gasket out of place, leading to a catastrophic failure.

Understanding Chemical Incompatibilities

While silicone offers good resistance to water, ozone, and UV light, it has several well-known chemical weaknesses that are critical to understand.

Swelling with Oils and Fuels

Silicone is highly susceptible to swelling and degradation when exposed to many hydrocarbon-based fluids. This includes gasoline, mineral oils, and many common industrial solvents. The material will absorb the fluid, swell significantly, and lose its structural integrity.

Degradation from Aggressive Chemicals

Concentrated acids and bases can attack and break down the silicone polymer. While it may hold up to mild solutions, it is not a good choice for aggressive chemical processing applications.

Vulnerability to High-Pressure Steam

While silicone has excellent high-temperature resistance in dry heat, it can be degraded by superheated or high-pressure steam over time. This process, known as hydrolysis, breaks down the polymer backbone of the material.

Making the Right Choice for Your Application

Selecting the correct gasket material requires matching the material's properties to the application's demands.

- If your primary focus is extreme temperature flexibility (hot or cold) in a low-pressure, static environment: Silicone is an excellent and often ideal choice, such as for oven doors or outdoor electrical enclosures.

- If your application involves high pressure, vacuum, or dynamic movement: Avoid silicone and consider a tougher material like Nitrile (Buna-N) for general use or Viton (FKM) for higher temperatures and chemical resistance.

- If the gasket will be exposed to oils, fuels, or hydrocarbon solvents: Do not use silicone. Nitrile is the standard, cost-effective choice for these applications.

Ultimately, understanding a material's limitations is the key to successful engineering design.

Summary Table:

| Limitation | Key Issue | Application Impact |

|---|---|---|

| Poor Physical Strength | Low tear & tensile strength, poor abrasion resistance | Unsuitable for high-pressure or dynamic sealing applications |

| High Gas Permeability | Gas molecules pass through the material | Poor performance in vacuum or long-term gas sealing |

| Chemical Incompatibility | Swells/degrades with oils, fuels, solvents, acids, bases | Cannot be used with many common industrial fluids |

| Steam Vulnerability | Degrades with high-pressure steam over time | Limited use in steam-related applications |

Don't Let the Wrong Gasket Material Compromise Your Application

Selecting the correct sealing component is critical for performance, safety, and longevity. While silicone has its place, many demanding applications in the semiconductor, medical, laboratory, and industrial sectors require superior materials like PTFE for exceptional chemical resistance, stability, and low permeability.

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—that overcome the limitations of silicone. We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your unique requirements.

Let our expertise guide you to the optimal sealing solution. Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers