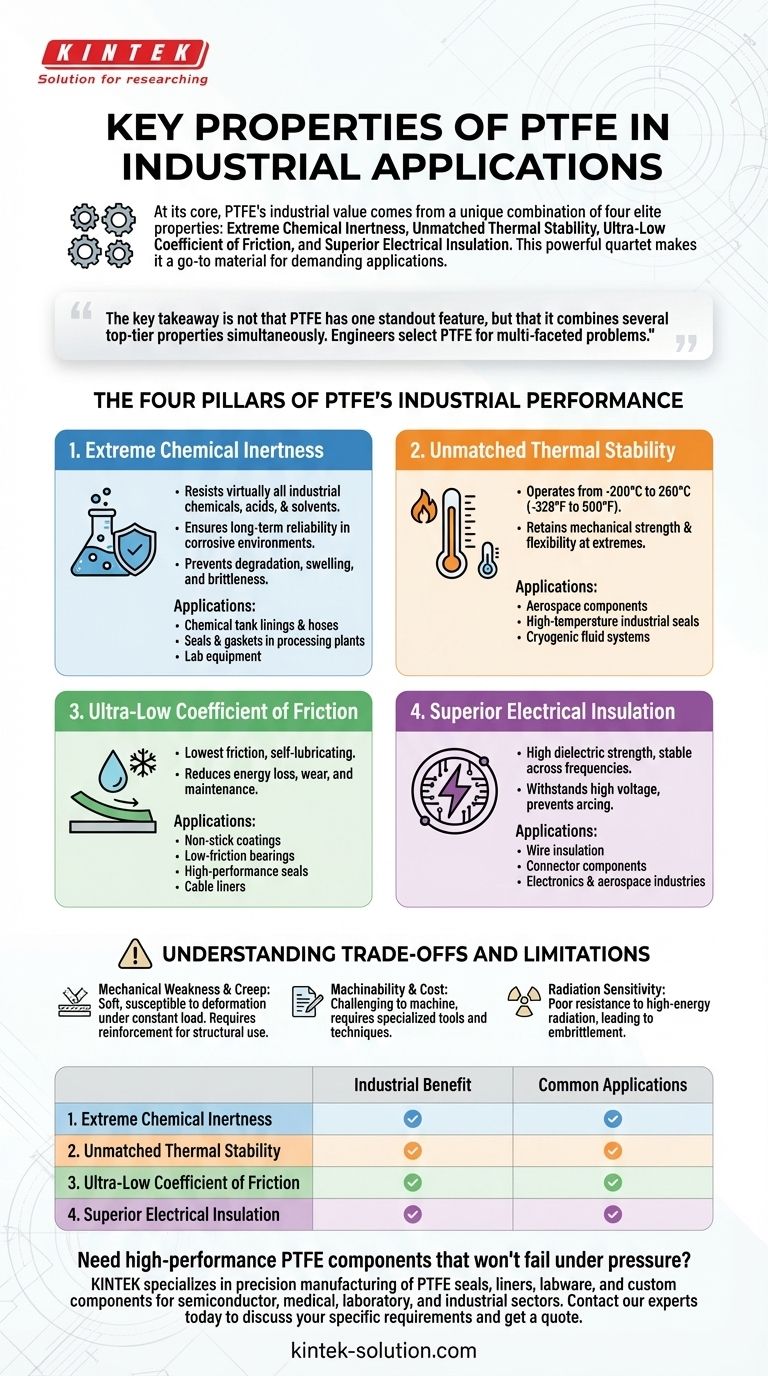

At its core, PTFE's industrial value comes from a unique combination of four elite properties. It is exceptionally resistant to chemicals, maintains its integrity across an extremely wide temperature range, possesses an incredibly low coefficient of friction, and serves as a superior electrical insulator. This powerful quartet makes it a go-to material for the most demanding applications where conventional materials would fail.

The key takeaway is not that PTFE has one standout feature, but that it combines several top-tier properties simultaneously. Engineers select PTFE when they face a multi-faceted problem—such as needing a part that can slide smoothly while resisting corrosive chemicals at high temperatures.

The Four Pillars of PTFE's Industrial Performance

To understand why PTFE (Polytetrafluoroethylene) is so versatile, we must examine its core properties and their direct impact on industrial design and reliability.

Pillar 1: Extreme Chemical Inertness

PTFE is one of the most chemically resistant materials known. It is virtually immune to attack from almost all industrial chemicals, acids, and solvents.

This level of resistance ensures long-term reliability in corrosive environments. Components made from PTFE will not degrade, swell, or become brittle when exposed to aggressive substances.

This makes it indispensable for applications like linings for chemical tanks and hoses, seals and gaskets in chemical processing plants, and lab equipment where purity is essential.

Pillar 2: Unmatched Thermal Stability

PTFE boasts one of the widest operating temperature ranges of any plastic, remaining functional from cryogenic lows of -200°C (-328°F) up to continuous service at 260°C (500°F).

While its melting point is around 327°C (621°F), its ability to retain mechanical strength and flexibility at these temperature extremes is its true advantage.

This thermal stability allows it to perform reliably in aerospace components, high-temperature industrial seals, and cryogenic fluid systems where other plastics would shatter or melt.

Pillar 3: Ultra-Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, comparable to wet ice on wet ice. This property is often referred to as being "self-lubricating."

This means parts can slide against each other with minimal energy loss or wear, often eliminating the need for liquid lubricants entirely. This reduces maintenance, contamination risk, and system complexity.

It is the ideal choice for non-stick coatings, low-friction bearings, high-performance seals, and cable liners that require smooth, effortless movement.

Pillar 4: Superior Electrical Insulation

PTFE is an exceptional electrical insulator with high dielectric strength, meaning it can withstand a very high voltage before it begins to break down and conduct electricity.

Its properties remain stable across a wide range of frequencies, making it particularly valuable for high-frequency applications like coaxial cables and circuit boards.

This makes it critical for the electronics and aerospace industries, where it is used for wire insulation, connector components, and insulators to ensure signal integrity and prevent electrical arcing.

Understanding the Trade-offs and Limitations

No material is perfect. While PTFE's properties are elite, understanding its limitations is critical for successful application.

Mechanical Weakness and Creep

PTFE is a relatively soft material. Under a constant load, especially at elevated temperatures, it is susceptible to creep, which is the tendency to slowly deform over time.

Designs must account for this behavior. For structural applications requiring high rigidity, unfilled PTFE is often unsuitable unless it is reinforced with fillers like glass, carbon, or bronze.

Machinability and Cost

Compared to common plastics like nylon or acetal, PTFE can be more challenging and costly to machine. Its softness requires very sharp tools and specific techniques to achieve tight tolerances without causing deformation.

Radiation Sensitivity

PTFE has poor resistance to high-energy radiation, such as gamma or electron-beam radiation. Exposure can cause the polymer chains to break down, leading to embrittlement and a rapid loss of mechanical properties.

Making the Right Choice for Your Application

Selecting PTFE is a decision driven by the need to solve a specific, often extreme, environmental challenge.

- If your primary focus is reliability in corrosive environments: PTFE's chemical inertness ensures components will not fail when exposed to aggressive acids, bases, or solvents.

- If your primary focus is reducing friction and wear: PTFE's self-lubricating properties are ideal for creating maintenance-free bearings, seals, and sliding surfaces.

- If your primary focus is high-temperature or cryogenic performance: PTFE's vast operating temperature range guarantees stability where other materials would become brittle or melt.

- If your primary focus is electrical safety and signal integrity: PTFE's excellent dielectric properties are essential for high-voltage and high-frequency applications.

Ultimately, PTFE is the material of choice when you cannot afford to compromise on performance in a harsh operational environment.

Summary Table:

| Key Property | Industrial Benefit | Common Applications |

|---|---|---|

| Extreme Chemical Inertness | Resists virtually all acids, solvents, and bases | Chemical tank linings, seals, labware |

| Wide Thermal Stability (-200°C to 260°C) | Performs in cryogenic and high-heat environments | Aerospace components, high-temp seals |

| Ultra-Low Coefficient of Friction | Self-lubricating, reduces wear and maintenance | Non-stick coatings, bearings, cable liners |

| Superior Electrical Insulation | Excellent dielectric strength, stable across frequencies | Wire insulation, circuit boards, connectors |

Need high-performance PTFE components that won't fail under pressure?

At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your parts deliver unmatched chemical resistance, thermal stability, and reliability.

Contact our experts today to discuss your specific requirements and get a quote for your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the mechanical properties of FR4 PCB material? Understanding Rigidity, Thermal Limits & Cost

- What are some alternatives to PTFE and how do they compare? A Guide to Fluoropolymer Selection

- How does PTFE perform as an electrical insulator? Unmatched Signal Integrity & High-Voltage Reliability

- Why is PTFE considered problematic despite being marketed as safe? The Hidden PFAS Lifecycle Risk

- What are the key properties that make PTFE commercially valuable? Unmatched Chemical Resistance & Low Friction

- What are the benefits of using Teflon in fiberglass? Achieve Unmatched Durability and Chemical Resistance

- What are the unique properties of PTFE that make it valuable in chemical industries? Discover Unmatched Chemical Resistance

- What are some common household applications of PTFE? Discover Its Hidden Uses Beyond Non-Stick Pans