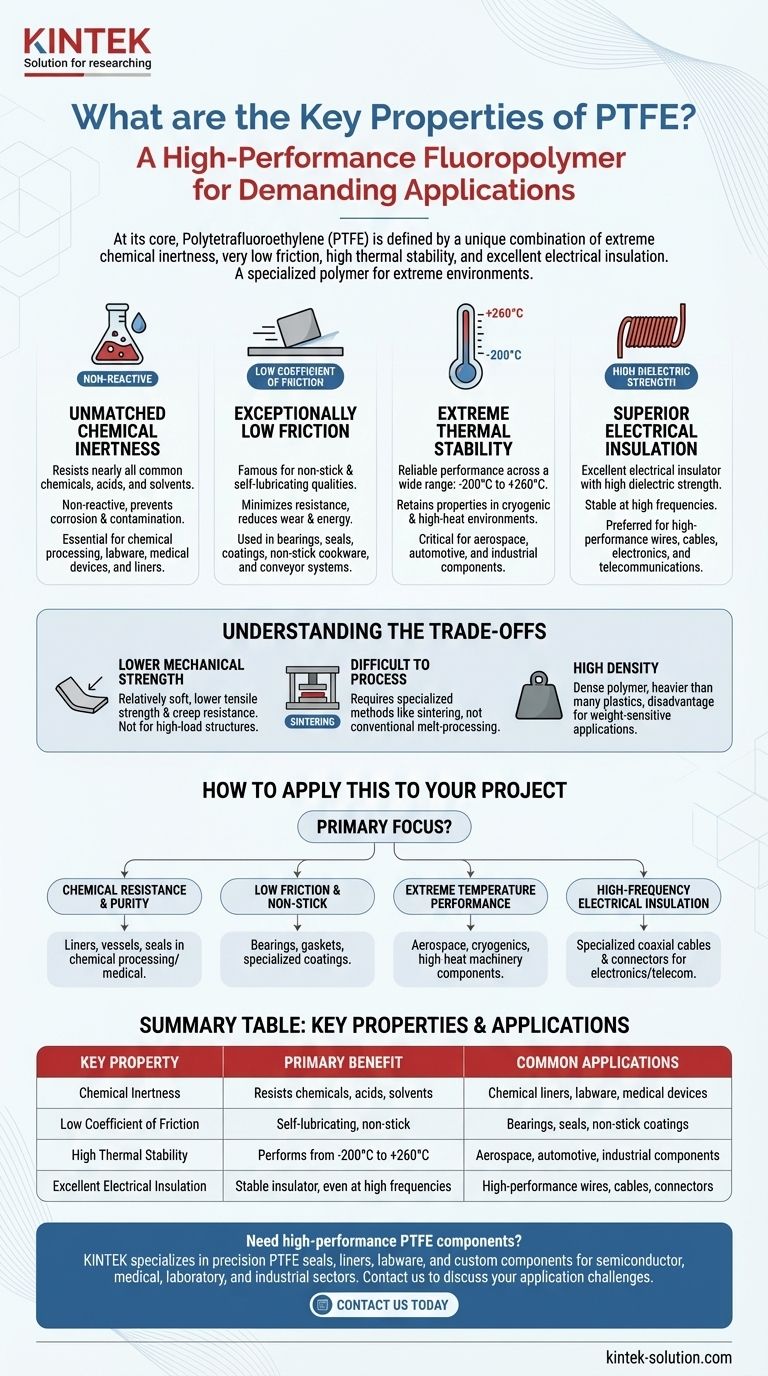

At its core, Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer defined by a unique combination of four elite properties: extreme chemical inertness, a very low coefficient of friction, high thermal stability across a wide temperature range, and excellent electrical insulation. These characteristics are not found together in most other materials, making PTFE an essential problem-solver for demanding industrial, chemical, and electronic applications.

PTFE is not just a single-purpose material; it is a specialized polymer chosen when performance in extreme environments is non-negotiable. Its value comes from the powerful synergy of its chemical, thermal, frictional, and electrical properties, allowing it to succeed where other materials would fail.

The Core Properties of PTFE Explained

To understand why PTFE is so versatile, we must examine each of its defining characteristics and the practical advantages they create.

Unmatched Chemical Inertness

PTFE is almost completely non-reactive. It offers exceptional resistance to nearly all common chemicals, acids, and solvents.

This inertness means it won't corrode, degrade, or contaminate the substances it comes into contact with, making it essential for use in chemical processing plants, laboratories, and medical devices. It is frequently used for liners in pipes, valves, and containers holding aggressive chemicals.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This gives it its famous non-stick and self-lubricating qualities.

Objects slide over its surface with minimal resistance, which reduces wear and energy consumption. This property is the reason it's used for everything from non-stick cookware to high-performance bearings, seals, and conveyor system components that operate without external lubrication.

Extreme Thermal Stability

This material performs reliably across an incredibly wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

Unlike many plastics that become brittle at low temperatures or melt at high temperatures, PTFE retains its core properties in both cryogenic and high-heat environments. This makes it a critical component in aerospace, automotive, and industrial applications where temperature fluctuations are extreme.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a very high dielectric strength, meaning it can withstand high voltages without breaking down.

Its properties remain stable even at high frequencies, making it a preferred material for insulating high-performance wires and cables, especially in electronics, computing, and telecommunications.

High Resistance to Water and UV

PTFE exhibits very poor water absorption, making it highly resistant to moisture.

Combined with its inherent resistance to UV light, this property ensures long-term durability and stability in harsh weather conditions or outdoor applications.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not the right choice for every situation. Acknowledging its limitations is key to using it effectively.

Lower Mechanical Strength

Compared to other engineering plastics like Nylon, PTFE is relatively soft. It has lower tensile strength and resistance to creep (the tendency to deform permanently under a constant load). This makes it unsuitable for high-load structural applications without reinforcement.

Difficult to Process

PTFE cannot be processed using conventional melt-processing techniques like injection molding. It requires specialized and often more costly methods like sintering, which can increase manufacturing complexity and cost.

High Density

PTFE is a dense polymer, making it heavier than many other plastics. This can be a disadvantage in applications where minimizing weight is a primary design goal.

How to Apply This to Your Project

Your choice to use PTFE should be driven by the most critical demand of your application.

- If your primary focus is chemical resistance and purity: PTFE is an unparalleled choice for lining pipes, vessels, and creating seals in chemical processing or medical fields.

- If your primary focus is low friction and non-stick surfaces: It is the definitive material for high-performance bearings, gaskets, and specialized coatings where lubrication is impossible or undesirable.

- If your primary focus is performance across extreme temperatures: PTFE is essential for components in aerospace, cryogenics, and high-heat industrial machinery.

- If your primary focus is high-frequency electrical insulation: It is a critical material for manufacturing specialized coaxial cables and connectors for the electronics and telecom industries.

Ultimately, PTFE should be viewed as a high-performance material for solving the most challenging engineering problems.

Summary Table:

| Key Property | Primary Benefit | Common Applications |

|---|---|---|

| Chemical Inertness | Resists nearly all chemicals, acids, and solvents. | Chemical processing liners, labware, medical devices. |

| Low Coefficient of Friction | Self-lubricating and non-stick. | Bearings, seals, non-stick coatings. |

| High Thermal Stability | Performs from -200°C to +260°C. | Aerospace, automotive, and industrial components. |

| Excellent Electrical Insulation | Stable insulator, even at high frequencies. | High-performance wires, cables, and connectors. |

Need high-performance PTFE components for your project?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. We combine expert material knowledge with custom fabrication services—from prototypes to high-volume orders—to deliver solutions that meet your exact specifications.

Contact us today to discuss how our PTFE expertise can solve your most demanding application challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components