At the core of its performance, Polytetrafluoroethylene (PTFE) is uniquely suited for sliding bearings due to a powerful combination of properties. Its exceptionally low coefficient of friction, high compressive strength, and resilience against chemical and thermal degradation allow it to support immense structural loads while enabling nearly frictionless movement between surfaces.

The true value of PTFE in bearings isn't just one single property, but how its low friction and high strength work together under pressure. Understanding this synergy is key, but success in application depends entirely on the design and integrity of the complete bearing assembly.

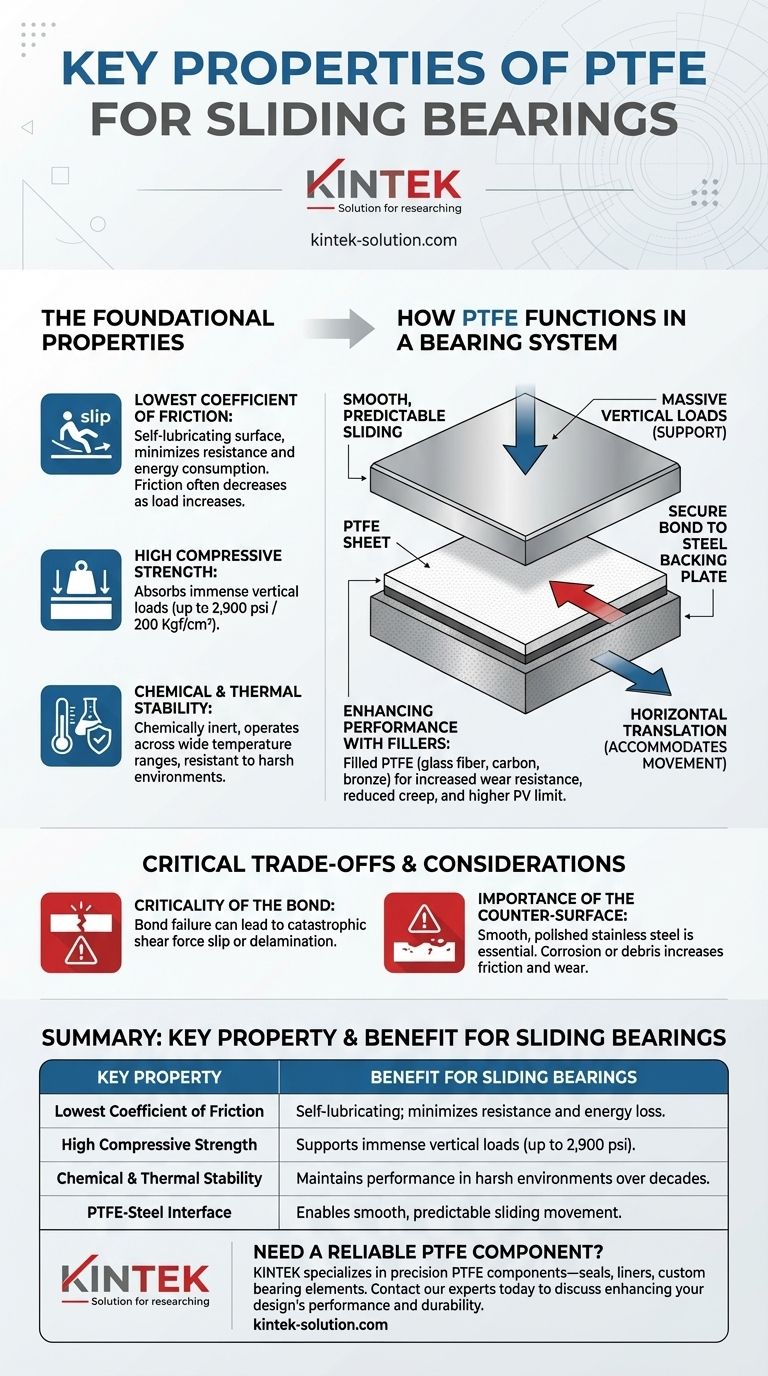

The Foundational Properties of PTFE Bearings

To understand why PTFE is a default choice for high-performance sliding applications, we must first examine its fundamental material characteristics.

The Lowest Coefficient of Friction

PTFE exhibits the lowest coefficient of friction of any known solid material. This creates a self-lubricating surface that minimizes resistance and energy consumption.

Crucially, this friction coefficient often decreases as the load increases, a rare and highly beneficial trait for structural bearings that must perform under immense pressure.

High Compressive Strength

Despite its slick surface, PTFE is not a soft material. It possesses excellent compressive strength, capable of absorbing pressures up to 2,900 psi (200 Kgf/cm²).

This robustness allows a thin sheet of PTFE to support the massive vertical loads found in applications like bridges and large buildings without being crushed or extruded.

Chemical and Thermal Stability

PTFE is almost completely chemically inert and can operate effectively across a very wide temperature range.

This resistance ensures the bearing maintains its integrity and performance over decades, even when exposed to harsh weather, de-icing salts, and other corrosive agents.

How PTFE Functions in a Bearing System

A material's properties are only as good as the system they are designed into. PTFE bearings are a perfect example of this principle, relying on a specific assembly to unlock the material's full potential.

The PTFE-Steel Interface

In a typical structural bearing, a sheet of PTFE is securely bonded to a steel backing plate.

A highly polished stainless steel plate is then placed on the PTFE surface. This specific pairing is critical, as the friction between PTFE and polished stainless steel is exceptionally low, allowing for smooth, predictable sliding.

Accommodating Load and Movement

This assembly serves two functions simultaneously. The high compressive strength of the PTFE allows the bearing to support massive vertical loads from the structure above.

At the same time, the low-friction interface allows for translation, or horizontal movement, in one or more directions. This is essential for accommodating thermal expansion and contraction, seismic activity, or other dynamic forces.

Enhancing Performance with Fillers

For even more demanding scenarios, filled PTFE is used. By adding fillers like glass fiber, carbon, or bronze to the PTFE matrix, manufacturers can enhance specific properties.

These enhancements can significantly increase wear resistance, reduce creep under load, and raise the overall pressure-velocity (PV) limit of the bearing.

Understanding the Critical Trade-offs

While PTFE is a remarkable material, its successful application hinges on understanding the limitations and potential failure points of the entire bearing system.

The Criticality of the Bond

The single most critical element in a PTFE bearing's design is the bond between the PTFE sheet and its steel backing plate.

High vertical loads on the bearing translate into powerful shear forces at this bond line. If the bond fails, the PTFE sheet can slip or delaminate, leading to a catastrophic failure of the entire bearing, even if the PTFE material itself is undamaged.

The Importance of the Counter-Surface

The low-friction properties of PTFE are only realized when sliding against a proper counter-surface. The system is designed around a smooth, polished stainless steel plate.

If this steel surface becomes corroded, scratched, or contaminated with abrasive debris, the coefficient of friction will increase dramatically, accelerating wear and impeding movement.

Making the Right Choice for Your Application

Choosing the right PTFE bearing configuration depends on balancing the specific engineering goals of your project.

- If your primary focus is accommodating extreme loads: Prioritize a design with proven high compressive strength and ensure the bond integrity calculations are verified for the expected shear forces.

- If your primary focus is enabling smooth, multi-directional movement: Focus on the PTFE-stainless steel interface, specifying a high-quality polished steel surface and a PTFE formulation optimized for low friction.

- If your primary focus is long-term durability in harsh environments: Select a PTFE grade with proven chemical and thermal resistance, and consider using filled PTFE variants for enhanced wear resistance.

Ultimately, leveraging PTFE's remarkable properties requires a holistic approach that considers the material, its assembly, and the specific demands of the entire system.

Summary Table:

| Key Property | Benefit for Sliding Bearings |

|---|---|

| Lowest Coefficient of Friction | Self-lubricating; minimizes resistance and energy loss. |

| High Compressive Strength | Supports immense vertical loads (up to 2,900 psi). |

| Chemical & Thermal Stability | Maintains performance in harsh environments over decades. |

| PTFE-Steel Interface | Enables smooth, predictable sliding movement. |

Need a reliable PTFE component for your high-performance application?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom bearing elements—for the semiconductor, medical, laboratory, and industrial sectors. We ensure the material integrity and precise fabrication critical for your project's success, from prototypes to high-volume orders.

Contact our experts today to discuss how our PTFE solutions can enhance your design's performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability