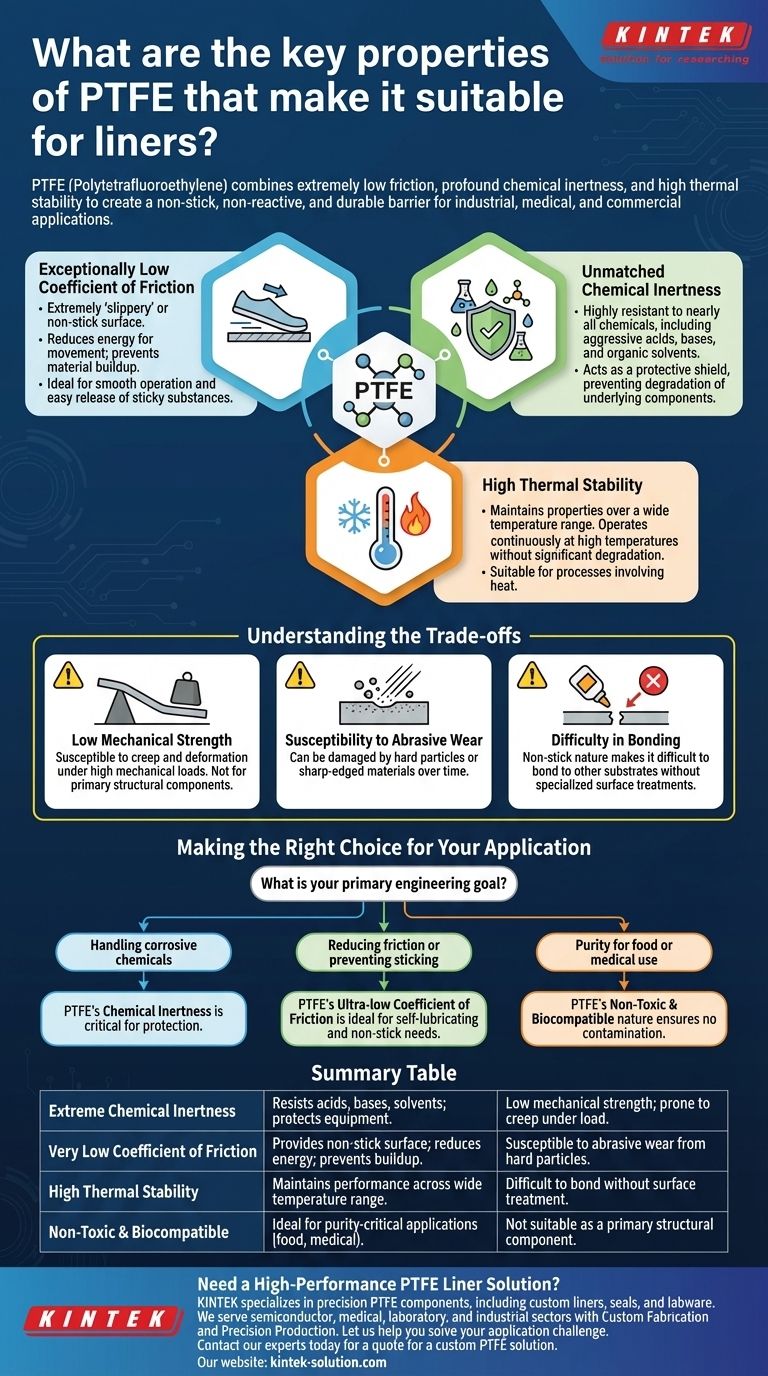

The key properties of Polytetrafluoroethylene (PTFE) that make it an exceptional liner material are its extremely low coefficient of friction, its profound chemical inertness, and its high thermal stability. This unique combination allows PTFE to create a non-stick, non-reactive, and durable barrier suitable for a vast range of demanding industrial, medical, and commercial applications.

PTFE is not just a single-purpose material; it's a unique synergy of non-stick, non-reactive, and temperature-resistant characteristics. This allows it to protect surfaces and facilitate smooth operation in environments where most other materials would fail.

The Core Properties of PTFE Liners

To understand if PTFE is the right choice, you must look beyond the surface-level benefits and understand the fundamental properties that drive its performance. Each characteristic addresses a distinct set of engineering challenges.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This gives it an extremely "slippery" or non-stick surface.

This property is critical for applications where smooth movement is required or where preventing material buildup is essential. It reduces the energy needed to move parts and ensures that viscous or sticky substances release easily.

Unmatched Chemical Inertness

The strength of the carbon-fluorine bonds in PTFE makes it almost completely inert. It is highly resistant to nearly all chemicals, including aggressive acids, bases, and organic solvents.

This makes PTFE liners an ideal choice for containing or transporting corrosive materials. The liner acts as a protective shield, preventing the chemical from degrading the underlying pipe, vessel, or component.

High Thermal Stability

PTFE maintains its key properties over a wide range of temperatures. It can operate continuously at high temperatures without significant degradation.

This thermal resistance ensures the liner remains stable and functional in processes involving heat, from industrial chemical reactions to food processing applications.

Non-Toxicity and Purity

PTFE is inherently non-toxic and biocompatible. It does not contaminate materials that come into contact with it.

This property is non-negotiable for applications in the food and beverage industry, pharmaceutical manufacturing, and medical devices, where purity and safety are paramount.

Understanding the Trade-offs

While its primary properties are exceptional, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Low Mechanical Strength

PTFE is a relatively soft material. It is susceptible to creep and deformation under high mechanical loads, especially at elevated temperatures.

It should not be used as a primary structural component. Its strength lies in being a surface liner, not in bearing significant physical stress.

Susceptibility to Abrasive Wear

While its low friction resists adhesive wear, PTFE is not highly resistant to abrasion from hard particles. Abrasive slurries or sharp-edged materials can physically damage a PTFE liner over time.

In such cases, a more abrasion-resistant material might be necessary, or the system design must account for potential wear.

Difficulty in Bonding

The very non-stick nature that makes PTFE valuable also makes it difficult to bond to other substrates. Adhering a PTFE liner often requires specialized surface treatments like chemical etching to create a bondable surface.

Making the Right Choice for Your Application

Your final decision depends entirely on your primary engineering goal.

- If your primary focus is handling corrosive chemicals: PTFE's chemical inertness is its most critical feature, protecting underlying substrates from nearly all industrial chemicals.

- If your primary focus is reducing friction or preventing sticking: The ultra-low coefficient of friction makes it ideal for applications like self-lubricating bearings or non-stick surfaces for easy release.

- If your primary focus is purity for food or medical use: Its non-toxic and non-reactive nature ensures that it will not contaminate the materials it contacts.

By understanding these core properties and their associated trade-offs, you can confidently determine if PTFE is the optimal solution for your engineering challenge.

Summary Table:

| Key Property | Why It Matters for Liners | Key Limitation |

|---|---|---|

| Extreme Chemical Inertness | Resists nearly all acids, bases, and solvents, protecting equipment. | Low mechanical strength; prone to creep under load. |

| Very Low Coefficient of Friction | Provides a non-stick surface, reduces energy use, and prevents buildup. | Susceptible to abrasive wear from hard particles. |

| High Thermal Stability | Maintains performance across a wide temperature range. | Difficult to bond to other materials without surface treatment. |

| Non-Toxic & Biocompatible | Ideal for food, pharmaceutical, and medical applications requiring purity. | Not suitable as a primary structural component. |

Need a High-Performance PTFE Liner Solution?

PTFE's unique combination of properties makes it the ideal choice for protecting equipment in the most demanding environments. At KINTEK, we specialize in manufacturing precision PTFE components, including custom liners, seals, and labware.

We serve the semiconductor, medical, laboratory, and industrial sectors by providing:

- Custom Fabrication: From initial prototypes to high-volume production runs.

- Precision Production: Ensuring every component meets your exact specifications for performance and durability.

Let us help you solve your application challenge. Contact our experts today to discuss your specific requirements and get a quote for a custom PTFE solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How is PTFE manufactured? Unlocking the Secrets of a High-Performance Polymer

- What are the applications of PTFE in the food and beverage industry? Ensure Purity, Safety, and Efficiency

- What is PTFE's resistance to hydrochloric acid at different concentrations? Discover Unmatched Chemical Inertness

- When did Teflon become a registered trademark, and what was an early use of the material? Discover Its Industrial Origins

- What are the main properties of Teflon material? Unrivaled Chemical Resistance & Non-Stick Performance

- What is virgin (unfilled) grade PTFE used for? Essential Applications for Ultimate Purity

- What makes PTFE unique compared to other engineering plastics? Unmatched Chemical & Thermal Resistance

- What makes PTFE suitable for medical applications? Unlock Biocompatible, Low-Friction Performance