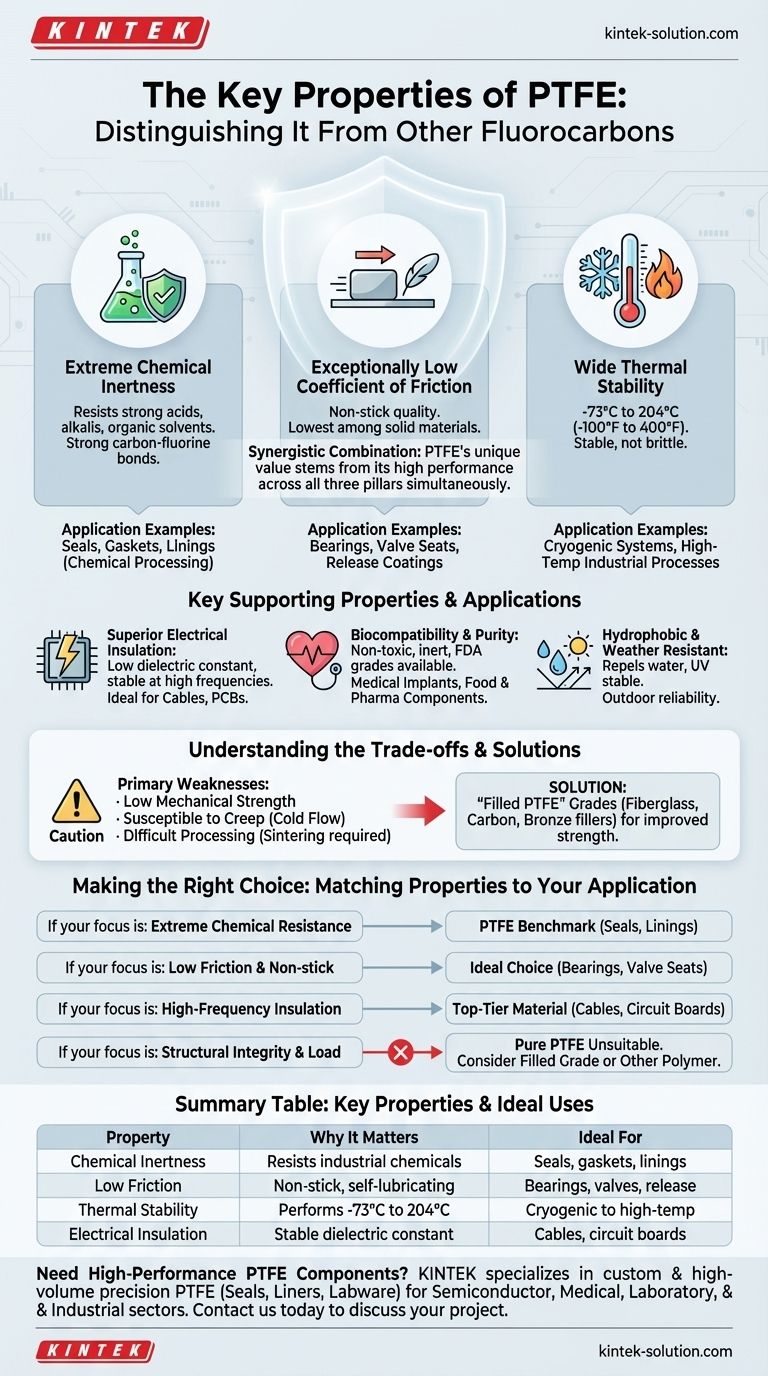

At its core, Polytetrafluoroethylene (PTFE) is distinguished by an unparalleled combination of three key properties: extreme chemical inertness, an exceptionally low coefficient of friction, and a very wide operating temperature range. While other fluoropolymers may excel in one area, PTFE's unique value comes from its high performance across all three, making it a benchmark material for demanding applications.

The defining characteristic of PTFE is not a single property, but rather its synergistic combination of chemical, thermal, and surface properties. This makes it uniquely suited for environments where multiple extreme conditions exist simultaneously.

The Pillars of PTFE's Performance

To understand why PTFE is so often specified for critical components, we must examine its core attributes individually.

Unrivaled Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, including strong acids, alkalis, and organic solvents. This extreme inertness stems from the strong carbon-fluorine bonds that make up its molecular structure.

This property makes it the material of choice for seals, gaskets, and linings used in aggressive chemical processing and transport.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This is the source of its well-known "non-stick" quality, famously marketed as Teflon.

This low-friction nature is critical for applications like self-lubricating bearings, low-torque valve seats, and any surface requiring easy release.

Wide Thermal Stability

PTFE maintains its properties across a remarkably broad temperature range, typically cited as -73°C to 204°C (-100°F to 400°F). It does not become brittle at low temperatures or degrade at high temperatures within this range.

This stability allows it to function reliably in applications from cryogenic systems to high-temperature industrial processes where other plastics would fail.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a very low dielectric constant, even at high frequencies. Its performance remains stable across wide temperature and frequency ranges.

These characteristics make it an ideal material for insulating high-performance wires and cables, as well as for manufacturing printed circuit boards used in microwave and radio-frequency applications.

Key Supporting Properties

Beyond the primary pillars, several other attributes solidify PTFE's role in specialized fields.

Biocompatibility and Purity

PTFE is non-toxic and biocompatible, meaning it does not react with bodily tissues or fluids. High-purity grades are available that meet FDA standards.

This makes it a vital material for medical implants, surgical tools, and components used in food and pharmaceutical manufacturing.

Hydrophobic Nature

The material has extremely low water absorption. It effectively repels water, which helps maintain its dimensional and electrical stability in humid environments.

UV and Weather Resistance

PTFE shows high resistance to degradation from sunlight, UV rays, and general weathering, allowing for long-term reliability in outdoor applications.

Understanding the Trade-offs

No material is perfect, and PTFE's unique strengths come with important limitations that must be considered. Its primary weaknesses are mechanical.

Low Mechanical Strength

Pure PTFE is a relatively soft material with low tensile strength and wear resistance. It is also susceptible to creep, or "cold flow," where the material deforms permanently under sustained pressure.

To counteract this, fillers like fiberglass, carbon, or bronze are often added to create "filled PTFE" grades with significantly improved mechanical properties.

Difficult Processing

Unlike many common plastics, PTFE cannot be processed using conventional melt-extrusion or injection molding techniques. It must be formed using specialized and often more costly methods like compression molding and sintering.

Making the Right Choice for Your Application

Selecting PTFE is about matching its unique profile to the demands of your environment.

- If your primary focus is extreme chemical resistance: PTFE is the benchmark for seals, gaskets, and linings in corrosive environments.

- If your primary focus is low-friction and non-stick surfaces: PTFE is the ideal choice for self-lubricating bearings, valve components, and release coatings.

- If your primary focus is high-frequency electrical insulation: PTFE's low and stable dielectric constant makes it a top-tier material for high-performance cables and circuit boards.

- If your primary focus is structural integrity and high mechanical loads: Pure PTFE is unsuitable; you must consider a filled grade or an entirely different polymer.

Ultimately, PTFE's value is defined by its unparalleled reliability when performance in harsh conditions cannot be compromised.

Summary Table:

| Key Property | Why It Matters | Ideal For |

|---|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals | Seals, gaskets, linings in corrosive environments |

| Low Coefficient of Friction | Self-lubricating, non-stick surface | Bearings, valve seats, release surfaces |

| Wide Thermal Stability | Performs from -73°C to 204°C (-100°F to 400°F) | Cryogenic to high-temperature processes |

| Superior Electrical Insulation | Stable dielectric constant at high frequencies | High-performance cables, circuit boards |

Need PTFE components that deliver unmatched performance in harsh conditions?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require custom prototypes or high-volume production, our expertise ensures your components meet the highest standards of chemical resistance, thermal stability, and reliability.

Contact us today to discuss your project and discover how our PTFE solutions can solve your most demanding application challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How does PTFE perform in high-temperature and dirty environments? Discover its Resilience and Reliability

- How does the non-stick property of PTFE benefit industrial applications? Boost Efficiency and Purity

- What are common uses of PTFE in laboratory and industrial settings? Unlock Chemical and Thermal Resistance

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are the key aspects of the CNC machining process for PTFE? Master Precision Machining for Soft Polymers

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- How does PTFE resist chemical attacks? The Science Behind Its Unmatched Chemical Inertness

- What happens when PTFE is incinerated? The Hidden PFAS Pollution Risk