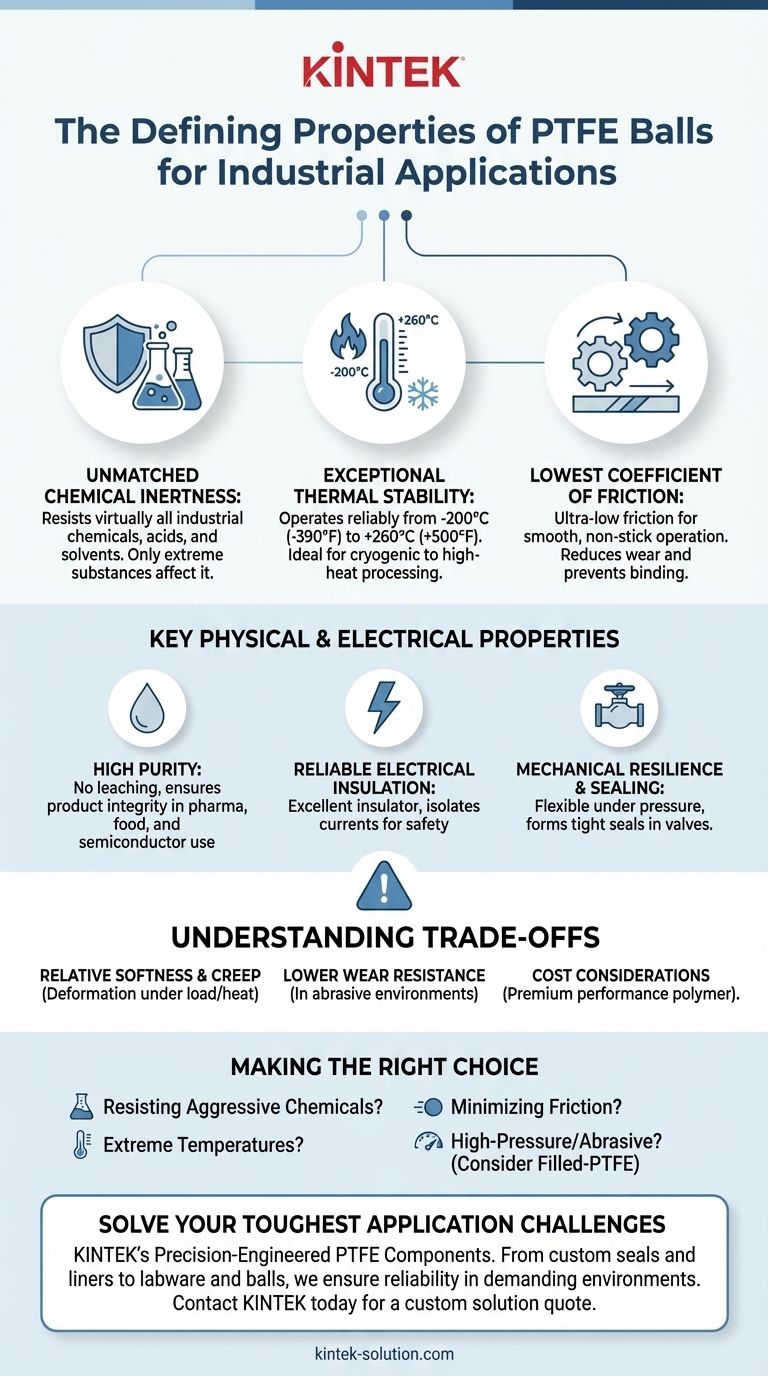

The defining properties of PTFE balls are their near-total chemical inertness, an exceptionally wide operating temperature range, and an extremely low coefficient of friction. This unique combination allows them to function reliably in harsh industrial environments where nearly all other plastic or metal components would quickly fail.

The core reason to specify PTFE balls is not just for one of their properties, but for their ability to solve problems in extreme environments. They are the material of choice when failure due to chemical attack, temperature fluctuation, or high friction is not an option.

Why PTFE Excels in Extreme Environments

Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer. Its molecular structure is the source of its remarkable industrial capabilities, making it a go-to material for critical components like valve balls, check balls, and bearings.

Unmatched Chemical Inertness

The PTFE polymer chain has a backbone of carbon atoms completely shielded by a sheath of fluorine atoms. This powerful carbon-fluorine bond is incredibly stable and non-reactive.

This structure makes PTFE balls resistant to virtually all industrial chemicals, including strong acids, aggressive bases, and corrosive solvents. Only rare substances like hot fluorine gas or certain molten metals can affect it.

Exceptional Thermal Stability

PTFE balls perform consistently across a vast temperature range, typically from -200°C (-390°F) to +260°C (+500°F).

This makes them suitable for applications ranging from cryogenic equipment to high-temperature chemical processing, where other materials would become brittle or melt.

The Lowest Coefficient of Friction

PTFE has one of the lowest friction coefficients of any known solid material, giving it a slick, non-stick surface.

This property is critical for applications involving moving parts. In valves or pumps, a PTFE ball ensures smooth, non-binding operation, reduces wear on adjacent parts, and prevents material buildup on its surface.

Key Physical and Electrical Properties

Beyond the primary performance characteristics, other intrinsic properties expand the utility of PTFE balls in specialized industrial roles.

High Purity and Non-Contamination

PTFE is an inherently pure material that does not leach chemicals or contaminate the media it contacts.

This makes it an ideal choice for applications in the pharmaceutical, food and beverage, and semiconductor industries, where maintaining product purity is paramount.

Reliable Electrical Insulation

PTFE is an excellent electrical insulator with very low electrical conductivity.

This property makes it suitable for components used in electrical equipment or in applications where isolating electrical currents is a safety or operational requirement.

Mechanical Resilience and Sealing

While not as hard as metal, PTFE is flexible and does not break easily under typical loads.

Its ability to deform slightly under pressure allows it to form excellent, tight seals, which is a critical function for balls used in check valves and shut-off valves.

Understanding the Trade-offs of PTFE

No material is perfect for every situation. Being an effective technical advisor means recognizing a material's limitations to prevent misapplication.

Relative Softness and Creep

PTFE is a relatively soft material. Under a constant, high static load (especially at elevated temperatures), it can be susceptible to "creep," or slow deformation over time. This must be a design consideration in high-pressure sealing applications.

Lower Wear Resistance

In applications with significant abrasive media, the low hardness of PTFE means it can wear more quickly than harder plastics or metals. For such scenarios, filled grades of PTFE (e.g., glass- or carbon-filled) are often used to improve durability.

Cost Considerations

PTFE is a premium-performance polymer, and its cost is higher than that of common plastics like nylon or polypropylene. Its use is justified when the severe operating conditions demand its unique combination of properties.

Making the Right Choice for Your Goal

Selecting the right material requires matching its properties to the primary challenge of the application.

- If your primary focus is resisting aggressive chemicals: PTFE is almost certainly the correct choice, as it is inert to nearly everything.

- If your primary focus is performance in extreme temperatures: PTFE's stability in both cryogenic and high-heat conditions makes it a premier option.

- If your primary focus is minimizing friction and ensuring smooth movement: The exceptionally low friction of PTFE makes it ideal for bearings, valve seats, and check balls.

- If your primary focus is a high-pressure, abrasive environment: Standard PTFE may be too soft; investigate filled-PTFE grades to enhance wear resistance and rigidity.

Understanding these core properties empowers you to select PTFE with confidence for your most demanding industrial applications.

Summary Table:

| Key Property | Industrial Benefit |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents. |

| Wide Temp Range (-200°C to +260°C) | Performs in cryogenic and high-heat processes. |

| Low Coefficient of Friction | Ensures smooth, non-binding operation of moving parts. |

| High Purity | Prevents contamination in pharma, food, and semiconductor uses. |

| Excellent Electrical Insulation | Isolates electrical currents for safety and performance. |

Solve your toughest application challenges with precision-engineered PTFE components from KINTEK.

Our expertise in custom fabricating PTFE seals, liners, labware, and balls ensures your critical systems operate reliably in the most demanding environments—from semiconductor manufacturing to medical and industrial processes. We deliver from prototypes to high-volume orders with an unwavering focus on precision and performance.

Contact KINTEK today to discuss your specific requirements and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are the benefits of PTFE-encapsulated O-rings? Superior Sealing for Harsh Chemical & High-Temp Environments

- What are the strengths and weaknesses of bronze filled PTFE? Enhance Performance in Demanding Applications

- What is the overall function of PTFE bushes in mechanical systems? Achieve Low-Friction, Maintenance-Free Operation

- What are the different types of PTFE seals? Choose the Right Seal for Your Application

- How does the price of PTFE sliding pads compare to regular rubber bearings? A Guide to High-Performance vs. Standard Components

- Why are PTFE lined butterfly valves considered cost-effective? Maximize ROI with Lower Lifetime Costs

- What are some common products made from PTFE? Discover Versatile Solutions for Harsh Environments