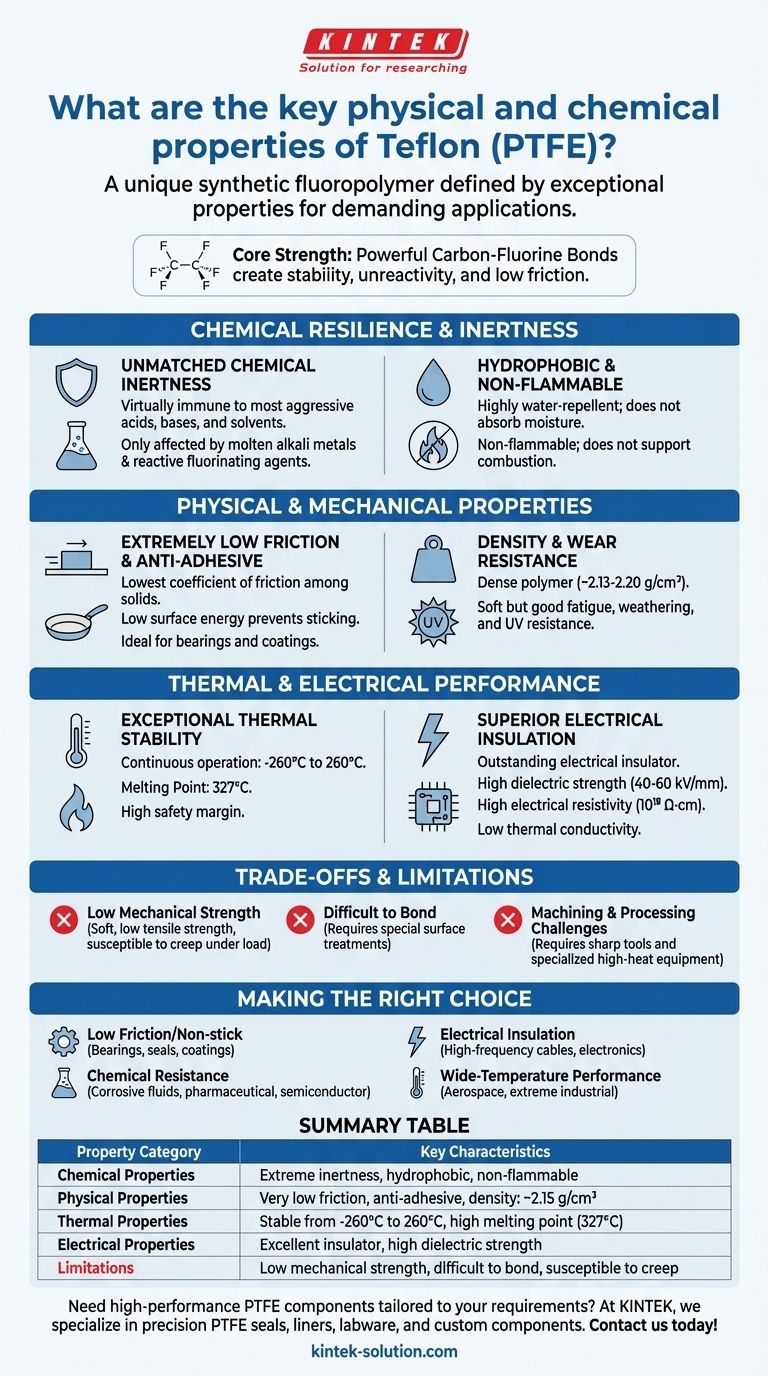

Teflon, or Polytetrafluoroethylene (PTFE), is a synthetic fluoropolymer defined by a unique combination of properties that make it invaluable in demanding applications. It is most famous for its exceptional non-stick surface, but its utility is equally driven by its extreme chemical inertness, high-temperature stability, and excellent electrical insulation.

The core strength of PTFE originates from the powerful carbon-fluorine bonds that form its molecular structure. This bond is so stable and strong that it makes the material highly unreactive and gives it an exceptionally low coefficient of friction, setting it apart from nearly all other polymers.

Understanding PTFE's Chemical Resilience

The chemical properties of PTFE are a direct result of its molecular structure, making it one of the most non-reactive materials known.

### Unmatched Chemical Inertness

PTFE is virtually immune to attack from the vast majority of chemicals, including aggressive acids, bases, and organic solvents.

Only a few substances, such as molten alkali metals and highly reactive fluorinating agents, are known to affect it. This makes it a primary choice for seals, gaskets, and linings in corrosive chemical environments.

### Hydrophobic and Non-Flammable

The material is highly water-repellent (hydrophobic) and does not absorb moisture. This contributes to its stability and performance in humid conditions.

Furthermore, PTFE is non-flammable and will not support combustion, a critical safety feature in many industrial and electrical applications.

The Core Physical and Mechanical Properties

While not known for its strength, PTFE's physical properties are central to its most common uses, from cookware to industrial bearings.

### Extremely Low Friction

PTFE possesses one of the lowest coefficients of friction of any known solid material. This inherent lubricity is what makes it an ideal non-stick coating and a top choice for low-friction bearings and sliding surfaces.

### Anti-Adhesive Surface

Its low surface energy prevents other materials from sticking to it. This "non-stick" characteristic is crucial not only for consumer cookware but also for industrial molds and conduits where preventing buildup is essential.

### Density and Wear Resistance

PTFE is a relatively dense polymer, with a density typically between 2.13 and 2.20 g/cm³. While it is soft, it offers good fatigue and weathering resistance, including strong performance against UV degradation.

Thermal and Electrical Performance

PTFE maintains its integrity across an exceptionally wide temperature range and is a world-class electrical insulator.

### Exceptional Thermal Stability

PTFE can operate continuously at temperatures up to 260°C (500°F) without significant degradation. Its high melting point of 327°C (621°F) provides a substantial safety margin.

It also retains its properties at cryogenic temperatures, remaining functional down to -260°C (-436°F).

### Superior Electrical Insulation

The strong carbon-fluorine bonds prevent the free movement of electrons, making PTFE an outstanding electrical insulator. It has very high dielectric strength (40-60 kV/mm) and electrical resistivity (10¹⁸ Ω·cm).

This makes it indispensable for high-frequency applications, such as coaxial cable insulation and components for printed circuit boards.

### Low Thermal Conductivity

PTFE is a poor conductor of heat, meaning it acts as a thermal insulator. This property must be considered in applications where heat dissipation is required.

Understanding the Trade-offs and Limitations

While its properties are exceptional, PTFE is not the solution for every engineering problem. Understanding its limitations is critical for proper material selection.

### Low Mechanical Strength

PTFE is a relatively soft material with low tensile strength and stiffness compared to other engineering plastics. It is susceptible to creep (deformation under sustained load) and is not suitable for high-load structural applications without reinforcement (e.g., glass or carbon fillers).

### Difficult to Bond

The same low surface energy that makes PTFE non-stick also makes it extremely difficult to bond to other materials using conventional adhesives. Attaching PTFE often requires special surface treatments like chemical etching to create a bondable surface.

### Machining and Processing

While machinable, the softness of PTFE requires sharp tools and specific techniques to achieve clean cuts and avoid deformation. Its high melting point also requires specialized equipment for processes like molding and extrusion.

Making the Right Choice for Your Goal

Selecting PTFE depends entirely on whether its unique strengths align with the primary demands of your application.

- If your primary focus is low friction or a non-stick surface: PTFE is an unparalleled choice for applications like bearings, seals, and specialized coatings where minimizing adhesion and resistance is critical.

- If your primary focus is chemical resistance: Its inertness makes it the default material for handling highly corrosive fluids in the chemical processing, pharmaceutical, and semiconductor industries.

- If your primary focus is electrical insulation: Its high dielectric strength and low loss factor are essential for high-frequency cables, connectors, and insulating components in demanding electronics.

- If your primary focus is wide-temperature performance: Its ability to function reliably in both cryogenic and high-heat environments makes it ideal for aerospace and extreme industrial applications.

By aligning these distinct properties with your specific engineering needs, you can effectively leverage PTFE's unique capabilities to solve complex challenges.

Summary Table:

| Property Category | Key Characteristics |

|---|---|

| Chemical Properties | Extreme inertness, hydrophobic, non-flammable |

| Physical Properties | Very low friction, anti-adhesive, density: ~2.15 g/cm³ |

| Thermal Properties | Stable from -260°C to 260°C, high melting point (327°C) |

| Electrical Properties | Excellent insulator, high dielectric strength |

| Limitations | Low mechanical strength, difficult to bond, susceptible to creep |

Need high-performance PTFE components tailored to your specific requirements?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get parts that leverage PTFE's unique properties to solve your most demanding challenges.

Contact us today to discuss your project and discover how our PTFE solutions can enhance your application's performance, reliability, and safety.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What are the primary applications of Teflon? Leverage Its Unique Properties for Your Industry

- What are the primary applications of PTFE? Unlocking High-Performance Solutions