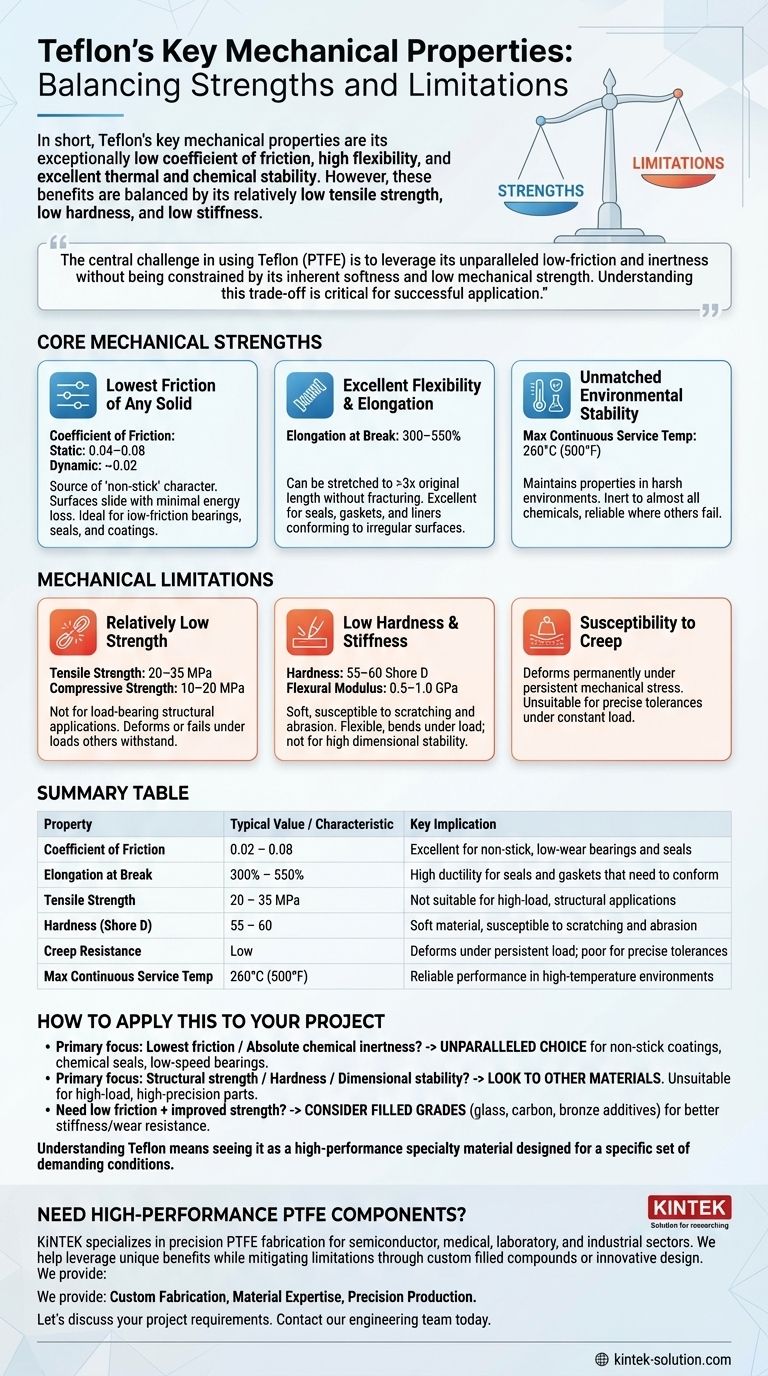

In short, Teflon's key mechanical properties are its exceptionally low coefficient of friction, high flexibility, and excellent thermal and chemical stability. However, these benefits are balanced by its relatively low tensile strength, low hardness, and low stiffness when compared to other engineering materials.

The central challenge in using Teflon (PTFE) is to leverage its unparalleled low-friction and inertness without being constrained by its inherent softness and low mechanical strength. Understanding this trade-off is critical for successful application.

Core Mechanical Strengths

Teflon's unique molecular structure, composed of strong carbon-fluorine bonds, gives rise to a set of highly desirable properties. These characteristics define where the material excels.

The Lowest Friction of Any Solid

Teflon is most famous for its extremely low coefficient of friction, with typical static values of 0.04–0.08 and dynamic values as low as 0.02.

This property is the source of its "non-stick" character. Mechanically, it means surfaces can slide against it with minimal energy loss or wear, making it a primary choice for low-friction bearings, seals, and coatings.

Excellent Flexibility and Elongation

Teflon exhibits a very high elongation at break, typically in the range of 300–550%.

This means it can be stretched to over three times its original length before it fractures. This high ductility makes it an excellent material for seals, gaskets, and liners that need to conform to irregular surfaces without breaking.

Unmatched Environmental Stability

While not purely mechanical, Teflon's thermal and chemical stability directly impacts its mechanical performance in harsh environments.

It maintains its properties over a wide temperature range, up to 260°C (500°F), and is inert to almost all chemicals. This allows it to function as a reliable mechanical component where other plastics would degrade and fail.

Understanding the Trade-offs: Mechanical Limitations

The properties that make Teflon unique also create its primary limitations. An objective assessment requires acknowledging its weaknesses, which are primarily related to strength and rigidity.

Relatively Low Strength

Teflon has a low tensile strength, typically 20–35 MPa, and a low compressive strength of 10–20 MPa.

While strong for a soft polymer, it is not a suitable material for load-bearing structural applications. It will deform or fail under loads that metals or even other engineering plastics could easily withstand.

Low Hardness and Stiffness

With a hardness of 55–60 Shore D, Teflon is a relatively soft material that is susceptible to scratching and abrasion.

Its low flexural modulus (0.5–1.0 GPa) indicates that it is very flexible and not rigid. It will easily bend under load rather than holding a precise shape, which is a critical consideration for components requiring high dimensional stability.

Susceptibility to Creep

A direct consequence of its low strength is "creep," which is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress.

If a constant load is applied to a Teflon component, it will slowly change shape over time. This makes it unsuitable for applications that require maintaining precise tolerances under a constant load.

How to Apply This to Your Project

Your material choice depends entirely on which properties are critical for your application's success.

- If your primary focus is the lowest possible friction or absolute chemical inertness: Teflon is an unparalleled choice for applications like non-stick coatings, chemical-resistant seals, and low-speed sliding bearings.

- If your primary focus is structural strength, hardness, or dimensional stability under load: You should look to other materials. Teflon's softness and tendency to creep make it unsuitable for high-load, high-precision mechanical parts.

- If you need a combination of low friction and improved mechanical strength: Consider filled grades of Teflon, which incorporate additives like glass, carbon, or bronze to improve stiffness and wear resistance, though this comes at the cost of some other properties.

Ultimately, understanding Teflon means seeing it not as an all-purpose plastic, but as a high-performance specialty material designed for a specific set of demanding conditions.

Summary Table:

| Property | Typical Value / Characteristic | Key Implication |

|---|---|---|

| Coefficient of Friction | 0.02 - 0.08 | Excellent for non-stick, low-wear bearings and seals |

| Elongation at Break | 300% - 550% | High ductility for seals and gaskets that need to conform |

| Tensile Strength | 20 - 35 MPa | Not suitable for high-load, structural applications |

| Hardness (Shore D) | 55 - 60 | Soft material, susceptible to scratching and abrasion |

| Creep Resistance | Low | Deforms under persistent load; poor for precise tolerances |

| Max Continuous Service Temp | 260°C (500°F) | Reliable performance in high-temperature environments |

Need High-Performance PTFE Components?

Understanding Teflon's properties is the first step. Applying that knowledge to design and manufacture a reliable component is the next. KINTEK specializes in precision PTFE fabrication for the semiconductor, medical, laboratory, and industrial sectors.

We help you leverage Teflon's unique benefits—like its unparalleled chemical resistance and low friction—while engineering solutions to mitigate its limitations, such as through custom filled compounds or innovative design.

We provide:

- Custom Fabrication: From prototypes to high-volume production.

- Material Expertise: Guidance on standard or filled PTFE grades for your specific needs.

- Precision Production: Components that meet exacting specifications for critical applications.

Let's discuss your project requirements. Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications