At its core, Polytetrafluoroethylene (PTFE) is an ideal material for slide bearings due to an unmatched combination of properties. Its defining characteristics are an extremely low coefficient of friction, inherent self-lubricating capabilities, complete chemical inertness, and stability across a wide temperature range. These features work together to create a bearing surface that is smooth, predictable, and requires virtually no maintenance.

The true value of PTFE isn't just one single property, but how its unique combination of low friction and extreme durability eliminates the need for external lubrication. This fundamentally simplifies bearing design, reduces long-term operational costs, and ensures reliable performance in demanding conditions.

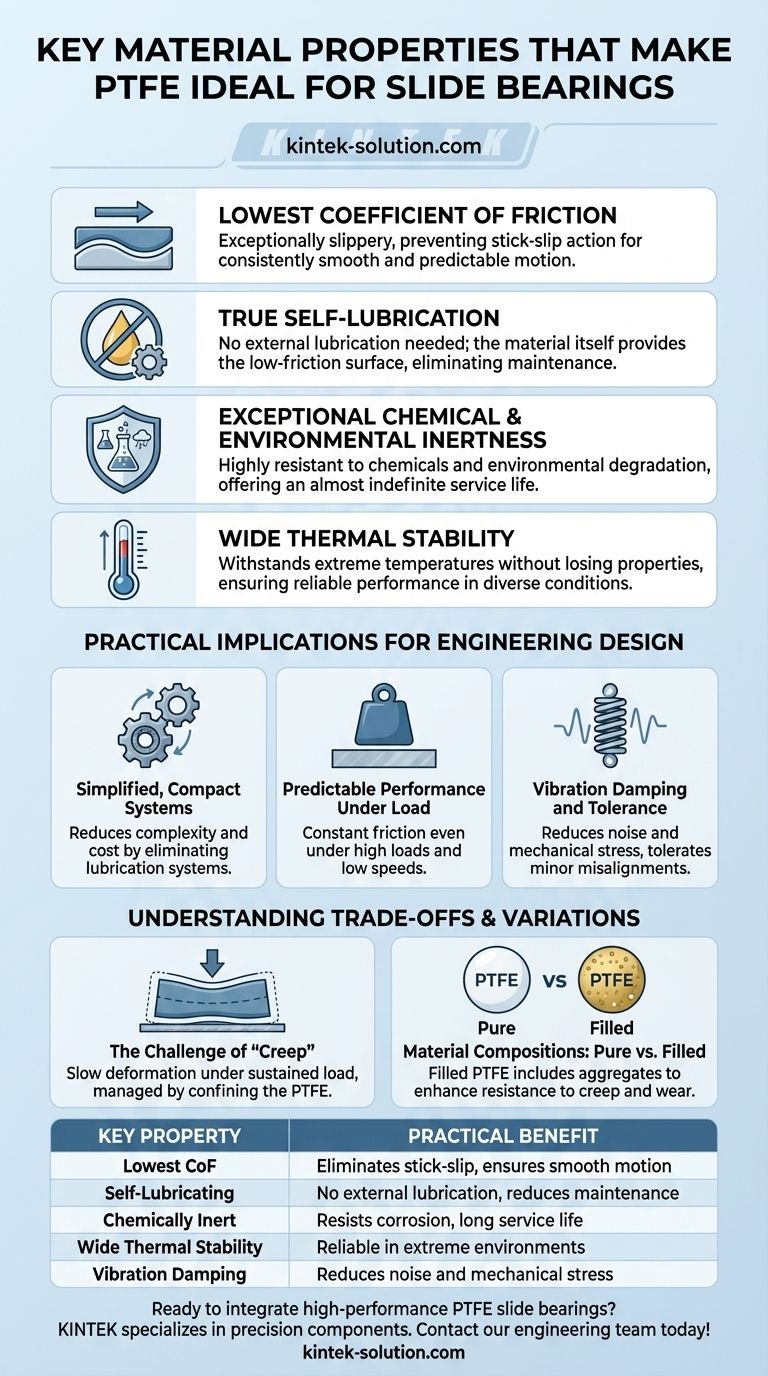

Deconstructing PTFE's Core Advantages

To understand why PTFE dominates this application, we must look at its fundamental material properties and the practical benefits each one provides.

The Lowest Coefficient of Friction

PTFE possesses the lowest coefficient of friction of any known solid material. This means it is exceptionally "slippery."

This property directly prevents a common engineering problem known as stick-slip action, where surfaces jerkily transition from static to dynamic friction. With PTFE, movement is consistently smooth and predictable from the moment a load is applied.

True Self-Lubrication

Unlike materials that require grease, oil, or other external lubricants, PTFE is self-lubricating.

The material itself provides the low-friction surface. This critical feature eliminates the need for lubrication systems, maintenance schedules, and inspections, making it ideal for inaccessible or critical structural components.

Exceptional Chemical & Environmental Inertness

PTFE is almost completely chemically inert. It does not react with chemicals and is highly resistant to weathering and environmental degradation.

This inertness gives PTFE bearings an almost indefinite service life from a material standpoint. They will not corrode or break down when exposed to harsh industrial chemicals, salt spray, or extreme weather.

Wide Thermal Stability

The material can withstand a very wide range of temperatures without losing its structural integrity or key properties.

This thermal stability ensures that the bearing will perform predictably in environments ranging from extreme cold to high-heat industrial settings, a versatility that few other materials can offer.

Practical Implications for Engineering Design

These material properties translate directly into tangible benefits for designers, engineers, and operators.

Simplified, Compact Systems

Because no external lubrication systems are needed, the entire bearing assembly can be simpler, more compact, and more cost-effective. This reduces both the initial fabrication complexity and the number of potential failure points.

Predictable Performance Under Load

PTFE slide bearings are particularly effective under high loads and low speeds. Critically, the coefficient of friction remains constant even under these worst-case conditions, giving engineers a reliable value for structural calculations.

Vibration Damping and Tolerance

The material has natural vibration-damping properties, which can help reduce noise and mechanical stress in a system. It also has a degree of flexibility that allows it to tolerate minor misalignments in construction.

Understanding the Trade-offs and Variations

While highly effective, it's crucial to understand the limitations of PTFE to apply it correctly.

The Challenge of "Creep"

Like many polymers, pure PTFE can be susceptible to creep, which is a slow deformation under sustained load.

Engineers manage this by confining the PTFE, often between two stainless steel plates. This design uses a reduced surface area of PTFE, which prevents it from creeping while still providing the low-friction interface.

Material Compositions: Pure vs. Filled

Slide bearings can be made from pure PTFE (typically white) or a composite.

Filled PTFE (often gold in color) includes aggregates like glass fibers. These fillers are added to enhance specific properties, most notably to increase the material's resistance to creep and wear.

How to Apply This to Your Project

Choosing the right material variant depends entirely on the primary goal of your application.

- If your primary focus is maximum simplicity and longevity: PTFE's self-lubricating and inert properties make it the definitive choice for maintenance-free systems, especially in hard-to-reach locations.

- If your primary focus is smooth, predictable motion: The ultra-low and constant coefficient of friction is the key benefit for eliminating stick-slip in sensitive structures or machinery.

- If your primary focus is operation in harsh environments: PTFE's chemical inertness and wide thermal stability ensure reliability where other materials would quickly degrade.

Understanding these foundational properties allows you to confidently specify PTFE for applications that demand simple, durable, and predictable motion.

Summary Table:

| Key Property | Practical Benefit for Slide Bearings |

|---|---|

| Lowest Coefficient of Friction | Eliminates stick-slip, ensures smooth, predictable motion |

| Self-Lubricating | No external lubrication needed; reduces maintenance and cost |

| Chemically Inert | Resists corrosion from chemicals and weather; long service life |

| Wide Thermal Stability | Performs reliably in extreme cold or high-heat environments |

| Vibration Damping | Reduces noise and mechanical stress in the system |

Ready to integrate high-performance PTFE slide bearings into your design?

At KINTEK, we specialize in manufacturing precision PTFE components, including seals, liners, and custom bearings for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a solution that offers:

- Maintenance-Free Operation: Leverage PTFE's self-lubricating properties to eliminate costly lubrication systems.

- Superior Durability: Benefit from exceptional chemical resistance and thermal stability for long-lasting performance in harsh conditions.

- Precision Engineering: From prototypes to high-volume orders, we deliver components that meet your exact specifications for smooth, reliable motion.

Let's discuss how our PTFE expertise can simplify your design and enhance your product's reliability. Contact our engineering team today for a custom solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How is structured PTFE manufactured? The Process Behind High-Performance PTFE Components

- Why is Teflon gland packing considered a future-proof solution for industrial sealing systems? Unmatched Chemical & Thermal Resilience

- How has sourcing Teflon parts from global suppliers improved supply chain efficiency?

- What are PTFE-coated gaskets and what are their limitations? Understanding the Risks of Surface Coatings

- How do PTFE envelope gaskets address the limitations of pure PTFE gaskets? Enhance Sealing Performance

- What is the difference between Teflon and generic PTFE? A Guide to High-Performance Fluoropolymers

- How do PTFE gaskets benefit the mechanical equipment industry? Enhance Equipment Reliability and Longevity

- What role do PTFE gaskets play in the energy and power industry? Ensuring Safety and Reliability in Critical Infrastructure