The suitability of PTFE for expansion joints stems directly from a unique combination of three core material properties: exceptional chemical resistance, high-temperature stability, and an extremely low coefficient of friction. These characteristics allow PTFE joints to perform reliably in aggressive industrial environments where traditional materials like rubber or metal would quickly degrade.

PTFE is the material of choice for expansion joints not because of a single standout feature, but because its combined chemical inertness and physical resilience solve the most demanding challenges in modern piping systems—handling corrosive media at high temperatures without failure.

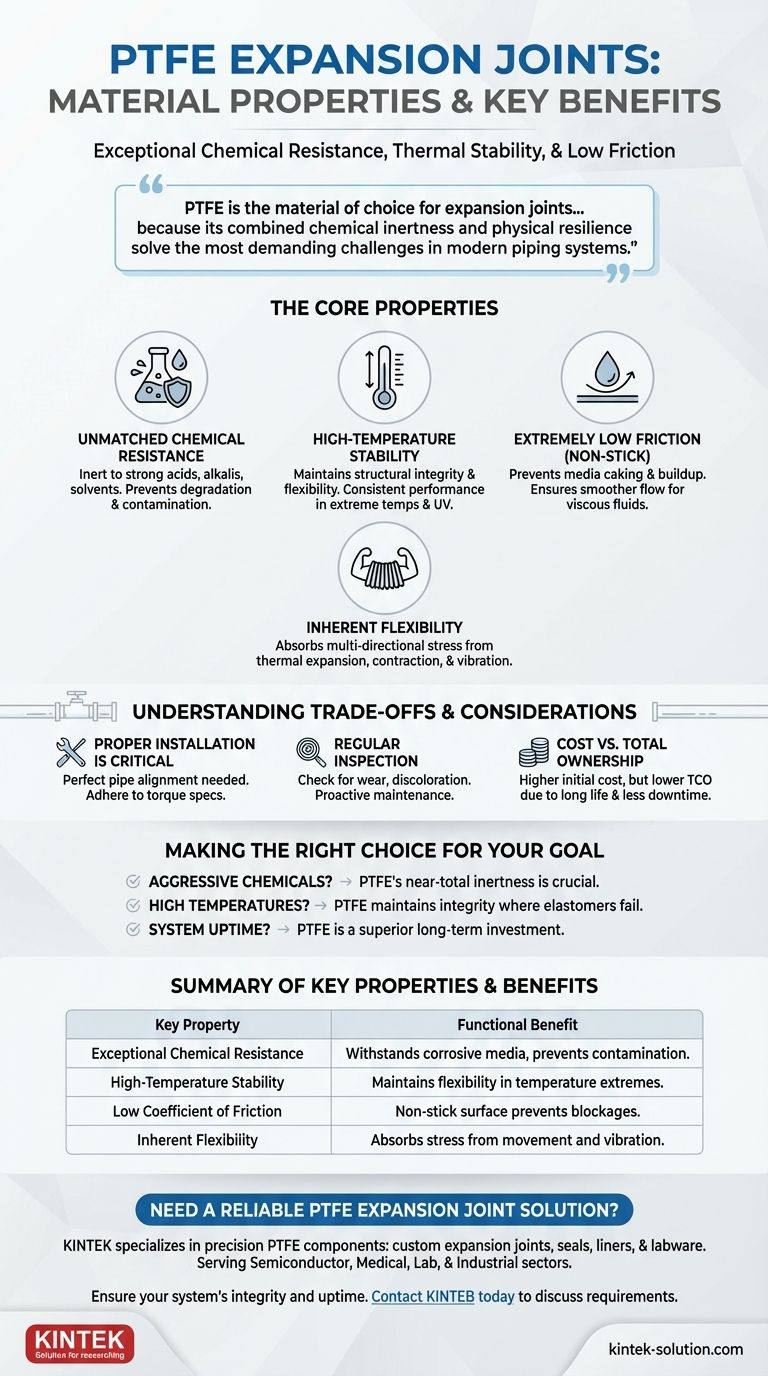

The Core Properties Driving PTFE's Performance

To understand why PTFE is so effective, we must examine how its fundamental properties translate into functional advantages within a high-stress piping system.

Unmatched Chemical Resistance

PTFE is virtually inert to most chemicals, including strong acids, alkalis, and organic solvents. This exceptional corrosion resistance is its most critical feature for chemical processing applications.

This inertness prevents the expansion joint material from degrading, swelling, or leaching, which ensures the integrity of the joint and prevents contamination of the process media.

High-Temperature Stability

PTFE maintains its structural integrity and flexibility across a wide temperature range. Unlike many elastomers that become brittle or soft at temperature extremes, PTFE performs consistently.

This thermal stability is crucial for systems that experience significant temperature fluctuations, ensuring the expansion joint can continue to absorb movement without failing. The material also exhibits excellent resistance to UV and weathering, making it suitable for outdoor installations.

Extremely Low Friction (Non-Stick Surface)

Known commercially as Teflon, PTFE has one of the lowest coefficients of friction of any solid material. This creates a non-stick surface inside the expansion joint.

This property is vital for preventing media from caking or building up on the internal surfaces, which could otherwise obstruct flow, increase pressure, and compromise the system. It ensures smoother operation, particularly with viscous or particulate-laden fluids.

Inherent Flexibility

While rigid, PTFE can be formed into flexible bellows that are essential for an expansion joint's function. It effectively absorbs the pipe movement caused by thermal expansion, contraction, and mechanical vibration.

This ability to absorb multi-directional stress protects the entire piping system from premature wear, fatigue, and catastrophic failure.

Understanding the Trade-offs and Considerations

While PTFE's properties are exceptional, its performance is not guaranteed without proper implementation. Achieving the full benefit of the material requires acknowledging its operational context.

The Importance of Proper Installation

The single greatest point of failure for any expansion joint is improper installation. For PTFE joints, ensuring perfect pipe alignment is critical to avoid placing uneven stress on the bellows.

Always adhere strictly to the manufacturer's installation guidelines, paying close attention to torque specifications and support requirements.

The Need for Regular Inspection

Even a material as durable as PTFE is subject to wear over time, especially in high-pressure or high-cycle applications. A regular inspection schedule is essential.

Look for any signs of wear, discoloration, or damage. Proactive maintenance is far less costly than the downtime caused by an unexpected joint failure.

Cost vs. Total Cost of Ownership

PTFE may have a higher initial material cost compared to some standard rubber alternatives. However, its extended service life, reduced need for replacement, and prevention of costly downtime in aggressive environments often result in a lower total cost of ownership.

Making the Right Choice for Your Goal

Selecting the right material is about matching its strengths to your system's specific demands.

- If your primary focus is handling aggressive chemicals: PTFE's near-total chemical inertness is its most critical feature, preventing joint degradation and process contamination.

- If your primary focus is high-temperature processes: PTFE maintains its structural integrity and flexibility at temperatures where traditional elastomers would fail.

- If your primary focus is reliability and system uptime: The combination of chemical, thermal, and physical resilience makes PTFE a superior long-term investment for critical applications.

Ultimately, choosing PTFE for an expansion joint is a decision to prioritize long-term reliability in the most demanding operational conditions.

Summary Table:

| Key Property | Functional Benefit for Expansion Joints |

|---|---|

| Exceptional Chemical Resistance | Withstands corrosive acids, alkalis, and solvents, preventing degradation and contamination. |

| High-Temperature Stability | Maintains integrity and flexibility across a wide temperature range, unlike standard elastomers. |

| Extremely Low Coefficient of Friction | Non-stick surface prevents media buildup, ensuring smooth flow and reducing blockages. |

| Inherent Flexibility | Effectively absorbs multi-directional stress from thermal expansion, contraction, and vibration. |

Need a Reliable PTFE Expansion Joint Solution?

Your demanding applications require components that won't fail. KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom expansion joints, seals, liners, and labware.

We serve the semiconductor, medical, laboratory, and industrial sectors, delivering the material advantages of PTFE with unmatched quality—from prototypes to high-volume orders.

Ensure your system's integrity and uptime. Contact KINTEB today to discuss your specific requirements and get a quote for a solution built to last.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications