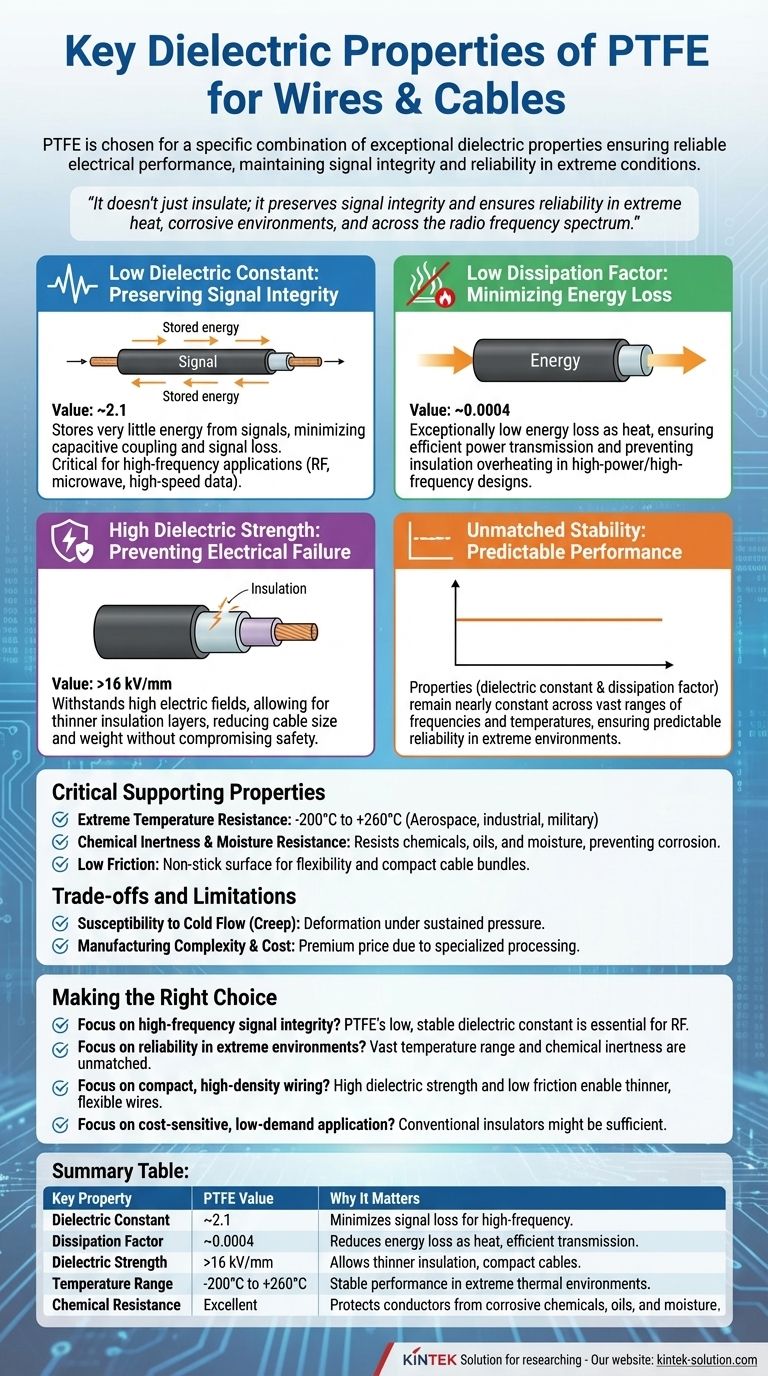

In wire and cable applications, PTFE is chosen for a specific combination of exceptional dielectric properties that ensure reliable electrical performance. Its key characteristics are an extremely low dielectric constant (around 2.1), a very low dissipation factor, high dielectric strength, and the stability of these properties across a wide range of frequencies and temperatures.

While many materials can insulate, PTFE's true value is its ability to maintain elite electrical and physical performance under the most demanding conditions. It doesn't just insulate; it preserves signal integrity and ensures reliability in extreme heat, corrosive environments, and across the radio frequency spectrum.

The Core Dielectric Advantages of PTFE

The term "dielectric properties" refers to how an insulating material behaves when exposed to an electric field. For wires and cables, these properties determine the efficiency and reliability of the system.

Low Dielectric Constant: Preserving Signal Integrity

The dielectric constant measures a material's ability to store electrical energy. In a cable, a lower value is almost always better.

PTFE's extremely low dielectric constant of approximately 2.1 means it stores very little energy from the signal passing through the conductor. This minimizes capacitive coupling and signal loss, which is critical for high-frequency applications like RF, microwave, and high-speed data cables.

Low Dissipation Factor: Minimizing Energy Loss

The dissipation factor (or loss tangent) quantifies how much electrical energy is absorbed by the insulator and lost as heat.

PTFE has an exceptionally low dissipation factor of around 0.0004. This means that very little signal energy is wasted, ensuring efficient power transmission and preventing the insulation from heating up, which is vital in high-power or high-frequency designs.

High Dielectric Strength: Preventing Electrical Failure

Dielectric strength is the maximum electric field an insulator can withstand before it breaks down and allows electricity to arc through.

With a dielectric strength greater than 16 kV/mm, PTFE provides robust insulation. This high strength allows for thinner insulating layers, reducing overall cable size and weight without compromising safety or performance.

Unmatched Stability Across Frequency and Temperature

Perhaps PTFE's most significant advantage is that its dielectric constant and dissipation factor remain nearly constant across a vast range of frequencies and temperatures.

This stability ensures that a cable's performance is predictable and reliable, whether it's carrying DC power in a sub-zero environment or a gigahertz signal next to a hot engine.

Why Supporting Properties Are Just as Critical

While the dielectric performance is central, PTFE's mechanical and chemical properties make it a truly superior choice for demanding wire and cable applications.

Extreme Temperature Resistance

PTFE has one of the widest operating temperature ranges of any polymer, performing consistently from -200°C to +260°C. This makes it the default choice for aerospace, industrial, and military applications where extreme heat or cold is expected.

Chemical Inertness and Moisture Resistance

PTFE is almost completely inert, offering excellent resistance to chemicals, oils, and solvents. Its resistance to water also makes it ideal for use in hot and wet environments, protecting the conductor from corrosion over its lifespan.

Low Friction for Compact and Flexible Designs

The famously low coefficient of friction of PTFE's "non-stick" surface provides a key mechanical advantage. It allows individual wires and cable layers to slide easily against one another, improving flexibility and making it easier to pull cables through tight conduits. This also enables more compact and dense cable bundles.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging PTFE's limitations is crucial for making an informed decision.

Susceptibility to Cold Flow (Creep)

PTFE is a relatively soft material and can be prone to "cold flow," or deformation over time when subjected to sustained pressure. In applications involving tight clamping or sharp-edged contacts, this must be considered in the design to prevent the insulation from thinning and failing.

Manufacturing Complexity and Cost

Processing PTFE is more challenging than conventional thermoplastics. These specialized manufacturing methods, combined with higher raw material costs, make PTFE-insulated wires and cables a premium-priced option compared to alternatives like PVC or polyethylene.

Making the Right Choice for Your Application

Your specific goal will determine whether PTFE's benefits justify its trade-offs.

- If your primary focus is high-frequency signal integrity: PTFE's low and stable dielectric constant is its most critical feature, making it essential for RF and high-speed data transmission.

- If your primary focus is reliability in extreme environments: The combination of its vast temperature range and chemical inertness is unmatched by most other insulators.

- If your primary focus is compact, high-density wiring: PTFE's high dielectric strength and low friction allow for thinner, more flexible wires that can be bundled tightly.

- If your primary focus is a cost-sensitive, low-demand application: The premium cost of PTFE may be unnecessary, and more conventional insulators could be sufficient.

By understanding this balance of elite electrical properties and robust physical characteristics, you can confidently specify PTFE for applications where performance and reliability cannot be compromised.

Summary Table:

| Key Property | PTFE Value | Why It Matters for Wires & Cables |

|---|---|---|

| Dielectric Constant | ~2.1 | Minimizes signal loss and capacitive coupling for high-frequency signals. |

| Dissipation Factor | ~0.0004 | Reduces energy loss as heat, ensuring efficient power transmission. |

| Dielectric Strength | >16 kV/mm | Allows for thinner insulation layers, enabling compact, lightweight cables. |

| Temperature Range | -200°C to +260°C | Maintains stable performance in extreme thermal environments. |

| Chemical Resistance | Excellent | Protects conductors from corrosive chemicals, oils, and moisture. |

Need PTFE Components for Your Critical Application?

PTFE's unique dielectric properties are essential for reliability in the most demanding environments. KINTEK specializes in the precision manufacturing of high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We combine material expertise with custom fabrication capabilities, from prototypes to high-volume production, to deliver solutions that meet your exact specifications for performance and durability.

Contact KINTEK today to discuss how our PTFE expertise can enhance the reliability and performance of your products.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What temperature range can PTFE balls typically withstand? From -200°C to +260°C with Key Limitations

- How are PTFE O-ring seals used in the automotive industry? Critical Sealing Solutions for High-Performance Vehicles

- What role do ceramic fillers play in PTFE laminates? Enhance Signal Integrity & Thermal Performance

- How are PTFE lip seals utilized in automotive applications? A Guide to Extreme Performance Sealing

- What temperature range can PTFE flange gaskets withstand? From Cryogenic -200°C to High-Temp +260°C

- What are the limitations of POM as a ball valve seat material? Key Risks & Safer Alternatives

- What are the key features of PTFE diaphragms? Maximize Performance in Demanding Applications

- What are the benefits of advanced PTFE compounds for temperature challenges? Achieve Unmatched Reliability in Extreme Heat