At its core, the utility of PTFE (Polytetrafluoroethylene) in cookware stems from a unique combination of three chemical properties: an extremely low surface energy that creates a non-stick finish, exceptional chemical inertness, and high thermal stability. These characteristics are a direct result of the powerful and stable bonds between carbon and fluorine atoms that make up the polymer.

The effectiveness of PTFE, widely known as Teflon, is not due to a single magic property but rather the molecular stability of the carbon-fluorine bond. This bond creates a chemically non-reactive and "slippery" surface that can withstand the typical heat of a kitchen stove.

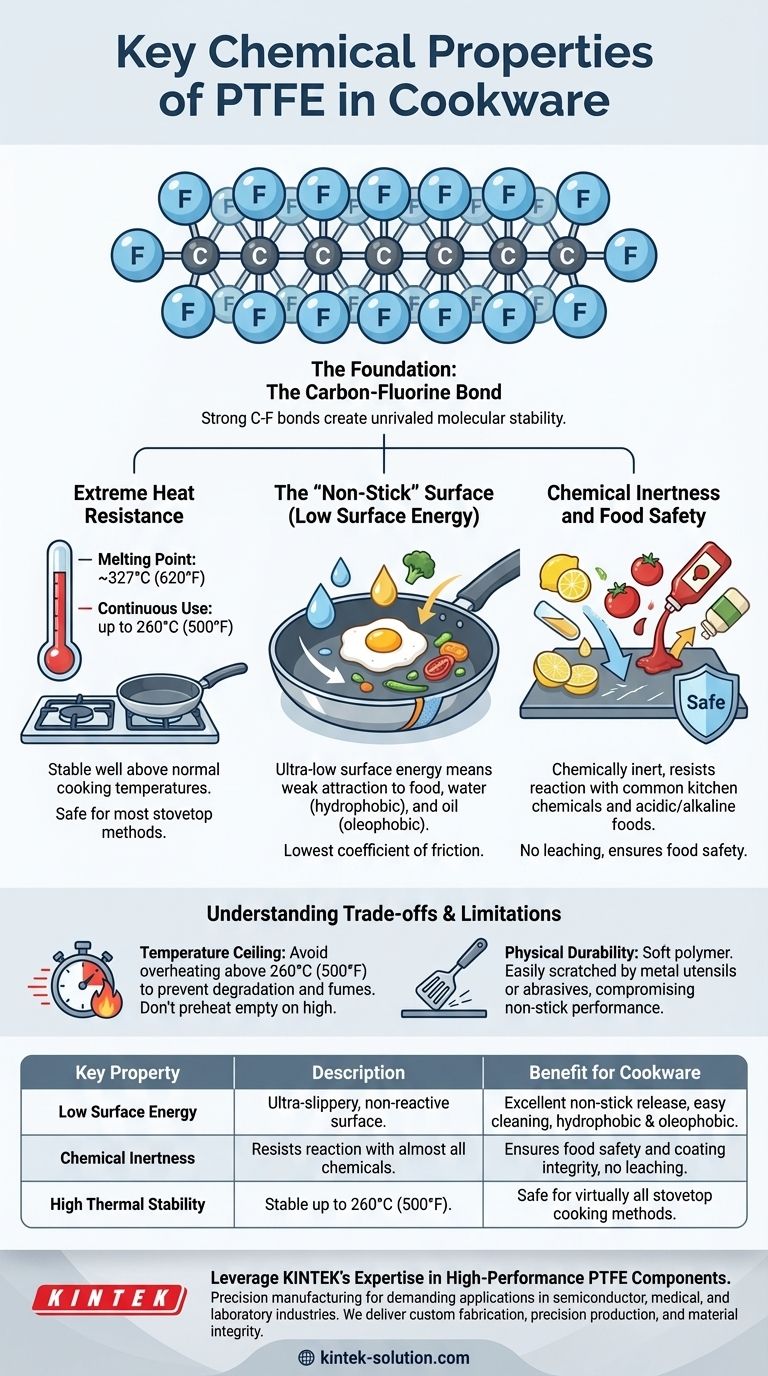

The Foundation: The Carbon-Fluorine Bond

To understand PTFE, we must first look at its fundamental structure. It is a fluorocarbon, a polymer built from a long chain of carbon atoms completely surrounded by fluorine atoms.

A Shield of Fluorine Atoms

The fluorine atoms are large and form a tight, protective sheath around the carbon backbone. This molecular structure is the origin of PTFE's most valuable characteristics.

Unrivaled Molecular Stability

The bond between carbon and fluorine is one of the strongest single bonds in organic chemistry. This makes the entire molecule incredibly stable and resistant to being broken apart by heat or chemical attack.

Key Properties for Cookware Explained

This stable molecular structure gives rise to the specific properties that make PTFE an ideal coating for non-stick pans.

Extreme Heat Resistance

PTFE has a very high melting point of approximately 327°C (620°F). This ensures the coating remains solid and stable well above normal cooking temperatures.

For practical purposes, PTFE coatings can operate continuously at temperatures up to 260°C (500°F), covering almost all stovetop cooking methods.

The "Non-Stick" Surface (Low Surface Energy)

The fluorine sheath gives PTFE an ultra-low surface energy. This means that the forces of attraction between the PTFE surface and other substances, like food, are exceptionally weak.

Because other molecules cannot get a chemical "grip" on the surface, food, water (hydrophobic), and oil (oleophobic) slide off easily. This is also what gives PTFE one of the lowest coefficients of friction of any solid.

Chemical Inertness and Food Safety

The strength of the carbon-fluorine bond makes PTFE chemically inert. It does not react with nearly any common chemical, including acidic foods like tomatoes or alkaline substances.

This non-reactivity is critical for food safety. Under normal cooking conditions, the coating will not break down or leach chemicals into your food, ensuring its integrity and your safety.

Understanding the Trade-offs and Limitations

While chemically robust, PTFE cookware is not without its practical limitations. Understanding these trade-offs is key to using it correctly.

The Temperature Ceiling

The primary limitation is its behavior at extreme heat. When heated above its recommended continuous use temperature of 260°C (500°F), PTFE can begin to degrade and release fumes. This is why empty non-stick pans should never be preheated on high for extended periods.

Physical Durability

While chemically resistant, PTFE is a relatively soft polymer. The non-stick surface can be easily scratched by metal utensils or abrasive cleaning pads. Any scratch compromises the coating's integrity and can diminish its non-stick performance.

Making the Right Choice for Your Goal

Applying this chemical knowledge helps you use PTFE cookware effectively and safely for its intended purpose.

- If your primary focus is convenience and low-fat cooking: PTFE's unparalleled non-stick surface is the ideal choice, requiring little to no oil.

- If your primary focus is high-heat searing: Be mindful of the temperature limits; materials like cast iron or stainless steel are better suited for temperatures exceeding 260°C (500°F).

- If your primary focus is longevity: Always use wood, silicone, or plastic utensils and gentle cleaning methods to preserve the physical integrity of the coating.

By understanding these core chemical principles, you can maximize the benefits of PTFE cookware while ensuring its safe and effective use in your kitchen.

Summary Table:

| Key Property | Description | Benefit for Cookware |

|---|---|---|

| Low Surface Energy | Creates an ultra-slippery, non-reactive surface. | Excellent non-stick release, easy cleaning, hydrophobic & oleophobic. |

| Chemical Inertness | Resists reaction with almost all chemicals, including food acids. | Ensures food safety and coating integrity, no leaching of chemicals. |

| High Thermal Stability | Stable up to 260°C (500°F) with a melting point of 327°C (620°F). | Safe for virtually all stovetop cooking methods. |

Leverage KINTEK's Expertise in High-Performance PTFE Components

Just as the right chemical properties make PTFE ideal for cookware, precision manufacturing makes KINTEK's PTFE components essential for demanding applications. We don't just supply PTFE; we engineer solutions.

For industries like semiconductor, medical, and laboratory, where chemical resistance, purity, and thermal stability are non-negotiable, KINTEK delivers:

- Custom Fabrication: From initial prototypes to high-volume production runs.

- Precision Production: Critical for seals, liners, labware, and other components where tolerances matter.

- Material Integrity: Guaranteeing the chemical properties that make PTFE valuable are fully realized in your final product.

Ready to solve your unique material challenge? Contact KINTEK today to discuss your project requirements and discover how our specialized PTFE manufacturing can bring reliability and performance to your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance