At its core, Polytetrafluoroethylene (PTFE) is a material of extremes. A PTFE plug is chosen when performance in harsh conditions is non-negotiable, offering an unparalleled combination of chemical inertness, temperature stability, and low-friction surface properties. Its primary characteristics are its extreme resistance to chemicals, its ability to function across a vast temperature range, its non-stick nature, and its excellent electrical insulation.

When standard materials fail due to chemical attack, extreme heat, or friction, PTFE provides a reliable solution. Understanding its unique profile—including its limitations—is key to leveraging it correctly.

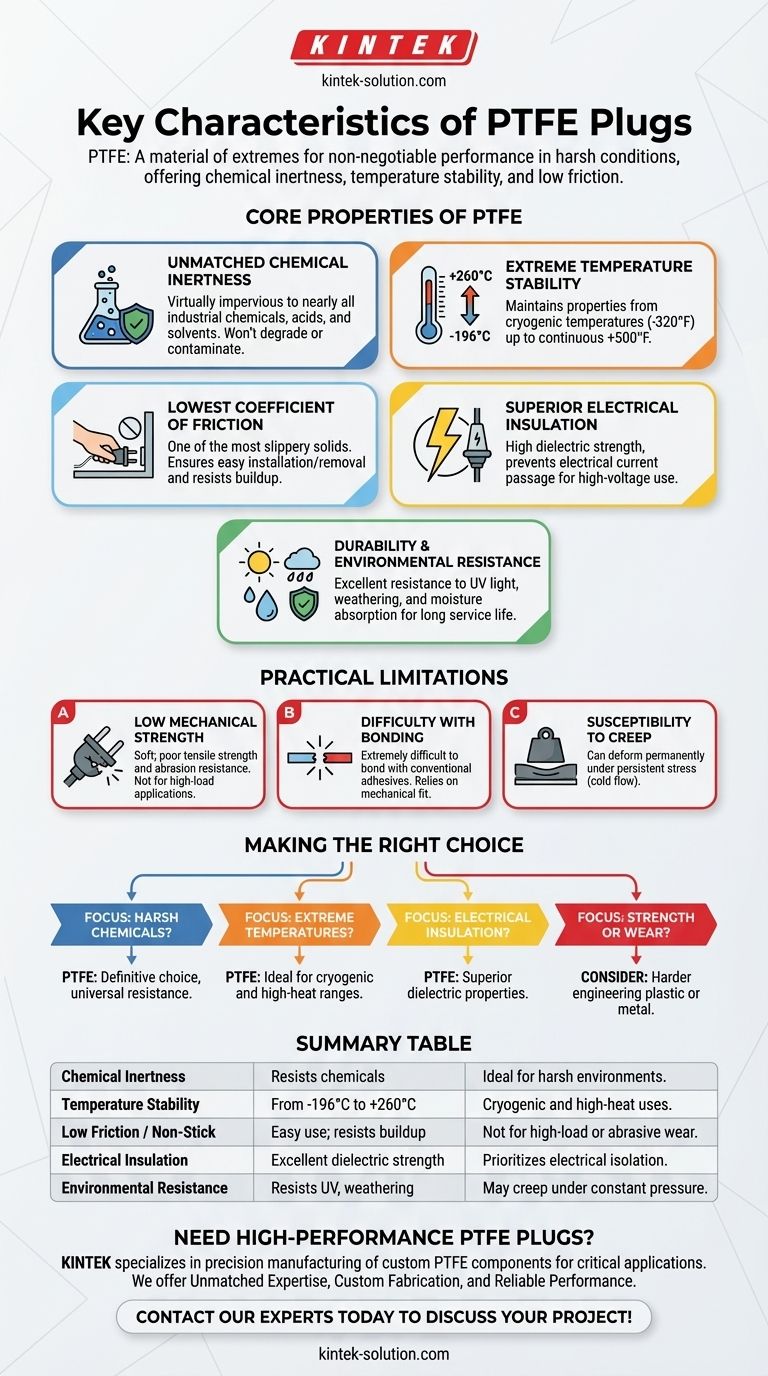

Unpacking the Core Properties of PTFE

To understand why PTFE plugs are specified for demanding applications, we must examine their fundamental characteristics. These properties are not just incremental improvements over other polymers; they represent a significant leap in performance for specific environments.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, acids, and solvents. It is virtually impervious to chemical attack, making it the ideal material for sealing ports and openings in chemical processing equipment or laboratory apparatus.

This inertness ensures that the plug will not degrade, swell, or contaminate the substances it comes into contact with, preserving both the integrity of the plug and the purity of the medium.

Extreme Temperature Stability

PTFE maintains its properties across an exceptionally wide thermal range, typically from cryogenic temperatures of -196°C (-320°F) up to a continuous service temperature of +260°C (+500°F).

This allows PTFE plugs to be used in applications ranging from liquid nitrogen handling to high-temperature engine and exhaust systems, where other plastics would become brittle or melt.

The Lowest Coefficient of Friction

Known as one of the most slippery solid materials in existence, PTFE has an extremely low coefficient of friction. This results in its well-known "non-stick" surface.

For plugs, this characteristic ensures easy installation and removal without galling or seizing, even after long-term service or thermal cycling. It also means the surface resists the buildup of deposits.

Superior Electrical Insulation

PTFE is an outstanding electrical insulator with high dielectric strength and low a dissipation factor. This makes it an ideal choice for plugs used to cap or seal components in electrical assemblies, connectors, and high-voltage equipment.

It effectively prevents electrical current from passing through, protecting both the equipment and personnel from shorts or electrical shock.

Durability and Environmental Resistance

Beyond chemicals and heat, PTFE is highly resistant to environmental factors. It demonstrates excellent resistance to weathering, UV light, and moisture absorption.

This inherent durability ensures a long service life, even in outdoor or wash-down environments where other materials would degrade over time.

Understanding the Practical Limitations

No material is perfect. While PTFE's strengths are significant, its weaknesses are equally important to understand for proper application.

Low Mechanical Strength

PTFE is a relatively soft material. It has high flexural strength, meaning it can bend without breaking, but it has poor tensile strength and abrasion resistance compared to engineering plastics like nylon or PEEK.

It is not suitable for high-load or structural applications where it would be subject to significant physical stress, pressure, or abrasive wear.

Difficulty with Bonding

PTFE's low-friction, non-stick surface makes it extremely difficult to bond to other materials using conventional adhesives. While surface treatments like chemical etching can prepare it for bonding, it is an additional, complex step.

This means a PTFE plug relies on its mechanical fit (tapered or straight) for sealing, not on an adhesive bond.

Susceptibility to Creep

Like many soft polymers, PTFE can be subject to "creep" or cold flow. This is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress.

In applications with constant high pressure, a PTFE plug might slowly deform over time, potentially compromising the seal. This must be considered in the design of the joint.

Making the Right Choice for Your Application

Selecting a PTFE plug is a decision driven by the specific demands of the operating environment. Use these guidelines to determine if it aligns with your goals.

- If your primary focus is sealing in a harsh chemical environment: PTFE is the definitive choice, offering near-universal resistance that protects your process and equipment.

- If your primary focus is performance in extreme temperatures: PTFE's vast operating range makes it ideal for both cryogenic and high-heat applications where other materials would fail.

- If your primary focus is electrical insulation: The outstanding dielectric properties of PTFE make it a superior material for isolating electrical components.

- If your primary focus is mechanical strength or wear resistance: PTFE is likely the wrong material; you should consider a harder engineering plastic or metal component.

Ultimately, choosing PTFE is a strategic decision to prioritize chemical, thermal, and electrical resilience above all else.

Summary Table:

| Key Characteristic | Benefit | Consideration |

|---|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals and solvents. | Ideal for harsh chemical environments. |

| Temperature Stability | Performs from -196°C to +260°C (-320°F to +500°F). | Suitable for cryogenic and high-heat applications. |

| Low Friction / Non-Stick | Easy installation/removal; resists deposit buildup. | Not suitable for high-load or abrasive wear. |

| Electrical Insulation | Excellent dielectric strength for high-voltage use. | Prioritizes electrical isolation. |

| Environmental Resistance | Resists UV, weathering, and moisture for long life. | May be subject to creep under constant pressure. |

Need High-Performance PTFE Plugs for Your Demanding Application?

KINTEK specializes in the precision manufacturing of PTFE components, including custom plugs, seals, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors where material performance is critical.

We provide:

- Unmatched Material Expertise: Leverage our deep knowledge of PTFE's properties to solve your most challenging sealing and insulation problems.

- Custom Fabrication: From initial prototypes to high-volume production runs, we tailor components to your exact specifications.

- Reliable Performance: Ensure the integrity of your processes with components built for extreme chemical, thermal, and electrical resilience.

Let us help you select or design the perfect PTFE solution. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance