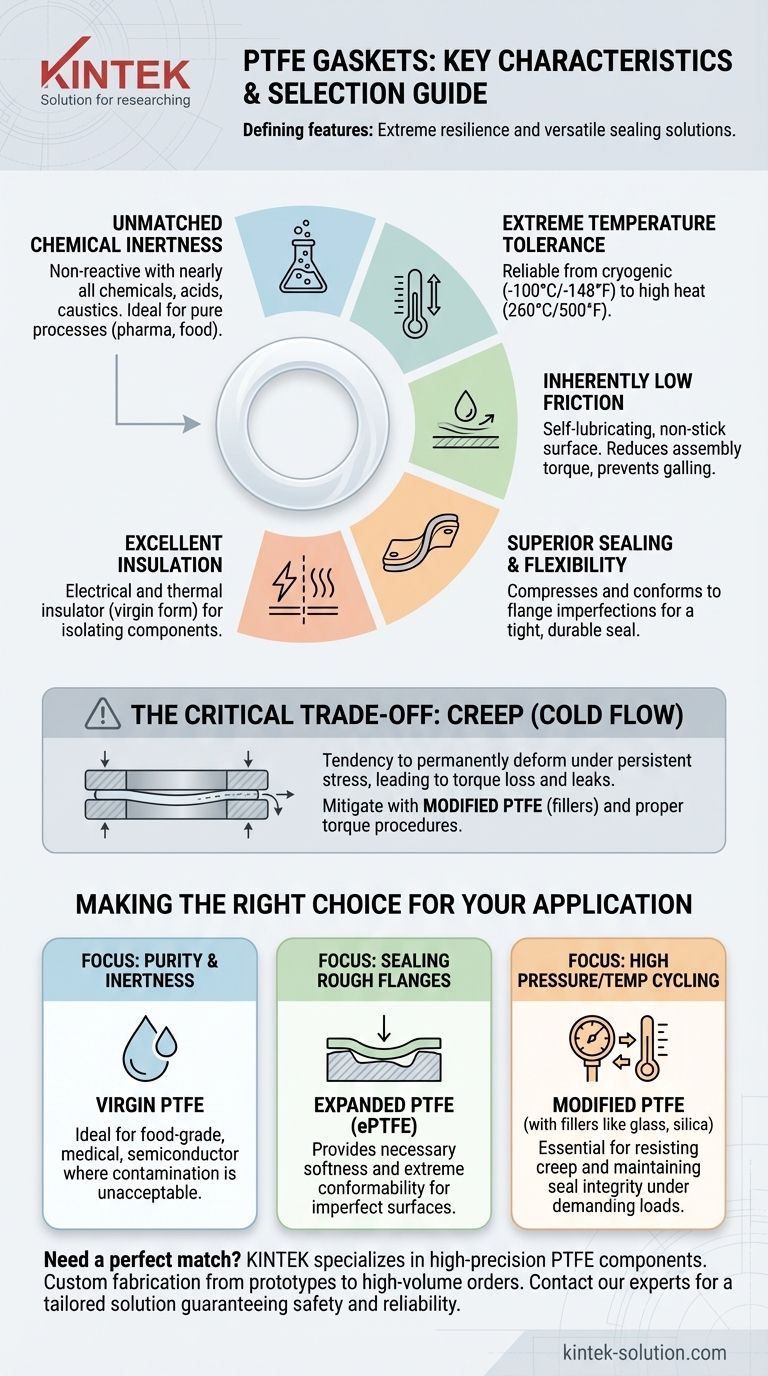

At their core, PTFE gaskets are defined by their extreme resilience and versatility. They are a superior sealing solution characterized by near-universal chemical resistance, a remarkably wide operating temperature range from cryogenic lows to high heat, and an inherently low-friction, non-stick surface. This unique combination makes them durable, flexible, and non-contaminating, suitable for the most demanding industrial environments.

The defining feature of PTFE is its chemical inertness and temperature stability, making it a default choice for harsh applications. However, understanding its mechanical limitations, particularly its tendency to "creep" under pressure, is critical to selecting the right type for reliable, long-term sealing.

Decoding the Core Properties of PTFE

The value of Polytetrafluoroethylene (PTFE) as a gasket material comes from a powerful synergy of several distinct characteristics. Each property addresses a specific challenge in industrial sealing.

Unmatched Chemical Inertness

PTFE is non-reactive with almost all industrial chemicals, acids, and caustics. This inertness prevents the gasket from degrading, swelling, or contaminating the process media, which is critical in pharmaceutical, food processing, and chemical industries.

Extreme Temperature Tolerance

PTFE gaskets perform reliably across a vast temperature spectrum, typically from cryogenic levels (-100°C / -148°F) up to 260°C (500°F). This allows a single material to be specified for both extreme cold and high-heat applications, simplifying inventory and design.

Inherently Low Friction

The material has one of the lowest coefficients of friction of any solid, giving it a self-lubricating, non-stick surface. This reduces torque needed during assembly, prevents galling on flange surfaces, and makes disassembly significantly easier.

Superior Sealing and Flexibility

PTFE is a flexible material that can compress and conform to minor surface imperfections on flanges, ensuring a tight and durable seal. This property, combined with its overall durability, ensures longevity even in harsh operational cycles.

Excellent Insulation

In its virgin form, PTFE is an excellent electrical and thermal insulator. It does not conduct electricity and resists heat transfer, making it valuable for isolating components in electronic assemblies or thermal management systems.

The Critical Trade-off: Creep and Cold Flow

While PTFE's properties are exceptional, it has one primary mechanical weakness that every engineer must account for: creep, also known as cold flow.

What is Creep?

Creep is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress. For a PTFE gasket, this means it can slowly "flow" out from between the flanges under constant bolt pressure, especially at elevated temperatures.

The Impact on Sealing

This cold flow leads to a loss of bolt torque over time. As the gasket thins, the clamping force decreases, which can compromise the integrity of the seal and eventually lead to leaks.

How to Mitigate the Risk

This limitation is precisely why different types of PTFE gaskets exist. Modified PTFE includes fillers like glass, silica, or carbon that are specifically added to the material matrix to significantly improve its creep resistance and mechanical stability. Proper installation and torque procedures are also vital.

Making the Right Choice for Your Application

The ideal PTFE gasket depends entirely on your operational priorities. Choosing correctly involves matching the material's strengths and weaknesses to the demands of the system.

- If your primary focus is purity and chemical inertness: Virgin PTFE is the definitive choice, especially for food-grade, medical, or semiconductor applications where contamination is not an option.

- If your primary focus is sealing rough or damaged flanges: Expanded PTFE (ePTFE) provides the necessary softness and extreme conformability to create a reliable seal on imperfect surfaces.

- If your primary focus is high pressure or temperature cycling: A modified PTFE with fillers like glass or silica is required to resist creep and maintain long-term seal integrity under demanding mechanical loads.

Understanding these characteristics empowers you to select a gasket that ensures both safety and long-term reliability in your system.

Summary Table:

| Key Characteristic | Benefit | Key Consideration |

|---|---|---|

| Chemical Inertness | Resists almost all chemicals, acids, and caustics. Ideal for pure processes. | N/A |

| Wide Temp Range | Performs from -100°C to 260°C (-148°F to 500°F). Simplifies material selection. | N/A |

| Low Friction / Non-Stick | Self-lubricating; reduces assembly torque, prevents galling. | N/A |

| Flexibility & Conformability | Creates a tight seal on imperfect flange surfaces. | N/A |

| Creep (Cold Flow) | N/A | Can lead to seal compression loss over time. Mitigate with modified PTFE or proper installation. |

Need a PTFE gasket that perfectly matches your application's demands?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, gaskets, liners, and labware. Whether your priority is ultimate chemical purity for semiconductor or medical applications, superior conformability for damaged flanges, or enhanced creep resistance for high-pressure systems, we deliver.

We provide custom fabrication from prototypes to high-volume orders, ensuring you get a sealing solution that guarantees safety, reliability, and longevity.

Contact our experts today to discuss your specific requirements and get a solution tailored for your success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry