In short, PTFE sheet material is exceptionally valuable for its unique combination of four key properties: extreme chemical resistance, a very wide operational temperature range, an incredibly low coefficient of friction, and excellent electrical insulation. These characteristics make it a go-to material for demanding applications where conventional plastics or metals would quickly fail.

PTFE is a high-performance polymer engineered for reliability in extreme conditions. Its primary benefit is not just one single attribute, but its ability to maintain high performance across a wide spectrum of chemical, thermal, and electrical challenges simultaneously.

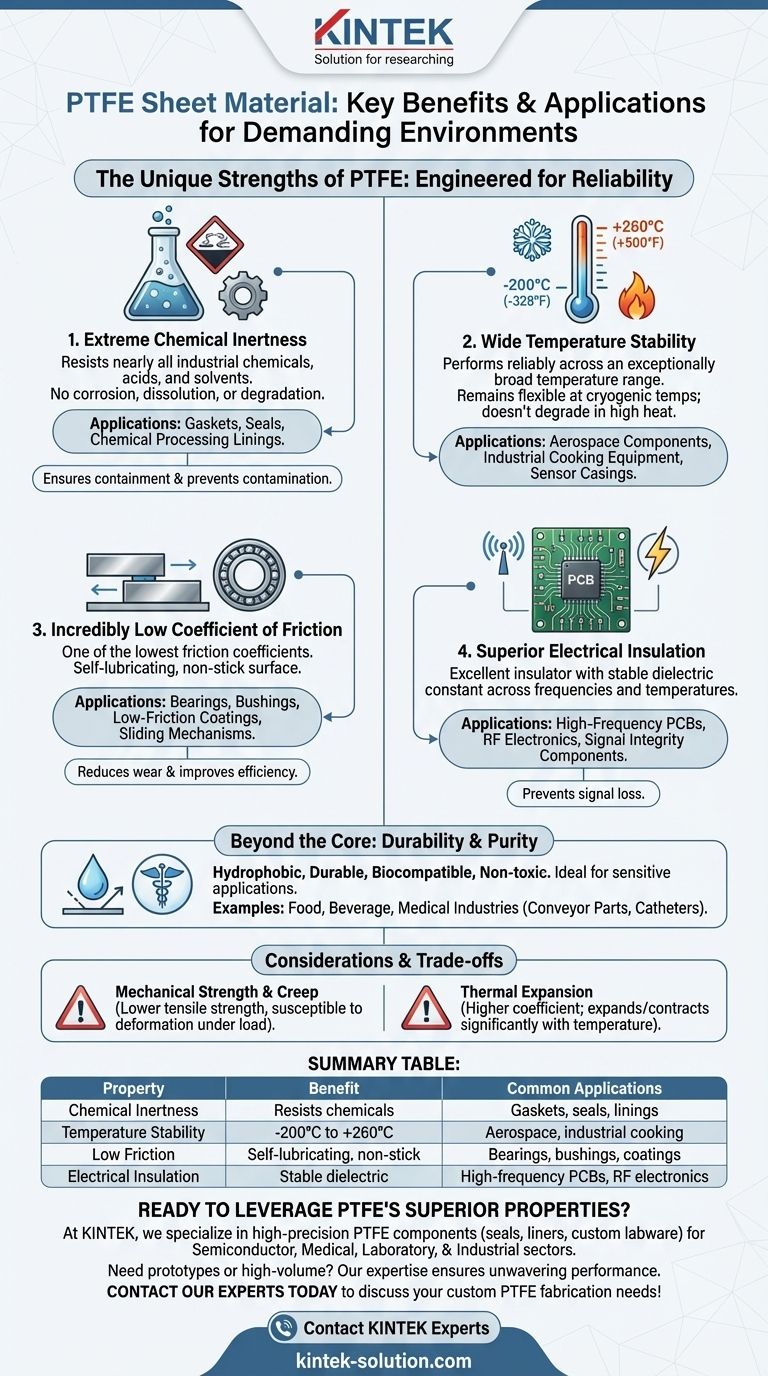

The Core Properties of PTFE Explained

To understand why PTFE (polytetrafluoroethylene), often known by the brand name Teflon, is so widely used, we must examine its fundamental characteristics. Each property solves a specific engineering problem.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, including aggressive acids, strong alkalis, and organic solvents. This inertness means it will not corrode, dissolve, or degrade when exposed to harsh substances.

This makes it an ideal material for gaskets, seals, and linings in chemical processing equipment, where it ensures containment and prevents contamination.

Extreme Temperature Stability

PTFE performs reliably across an exceptionally broad temperature range, typically from -200°C to +260°C (-328°F to +500°F). It remains flexible at cryogenic temperatures and does not degrade in high heat.

This thermal stability allows it to be used in everything from aerospace components to industrial cooking equipment and sensor casings exposed to severe temperature swings.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This gives it a "self-lubricating" or non-stick quality, allowing surfaces to slide against each other with minimal resistance.

This property is critical for applications involving rotating or sliding mechanisms, such as bearings, bushings, and low-friction coatings, where it reduces wear and improves efficiency.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a very high dielectric strength. Crucially, its dielectric constant remains stable across a wide range of frequencies and temperatures.

This consistency makes it indispensable in high-frequency electronics, such as for PCBs (Printed Circuit Boards) used in RF and high-speed digital applications, where it prevents signal loss and ensures signal integrity.

Durability and Purity

Beyond its primary traits, PTFE is also hydrophobic (resists moisture), durable, and often biocompatible and non-toxic. This makes it suitable for use in sensitive applications.

Its clean, non-stick surface is easy to maintain, and its non-toxic nature makes it a safe choice for the food, beverage, and medical industries for parts like conveyor components, catheters, and syringes.

Understanding the Trade-offs and Considerations

While PTFE's benefits are significant, it is a specialized material. A complete understanding requires acknowledging its limitations, which often dictate its proper application.

Mechanical Strength and Creep

Compared to engineering metals or even other high-performance plastics, PTFE is relatively soft and has lower tensile strength. It is also susceptible to "creep" or cold flow, meaning it can deform slowly over time under a constant load. This must be accounted for in structural designs.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than many other materials. This means it will expand and contract more significantly with temperature changes, a factor that is critical when designing parts with tight tolerances.

Cost vs. Performance

PTFE is a premium material, and its cost reflects its high-performance capabilities. Its use is most easily justified in applications where its unique combination of properties is not just beneficial but absolutely necessary for performance and safety.

Making the Right Choice for Your Goal

Selecting PTFE is about matching its unique strengths to the specific demands of your project.

- If your primary focus is sealing against aggressive chemicals: PTFE's inertness makes it the definitive choice for gaskets and seals in chemical processing or laboratory equipment.

- If your primary focus is high-frequency electronics: Its stable dielectric constant is essential for ensuring signal integrity in RF circuits and high-speed digital PCBs.

- If your primary focus is reducing friction in moving parts: Its self-lubricating properties are ideal for creating durable, low-wear bearings, bushings, and slide plates.

- If your primary focus is purity and safety: Its non-toxic and biocompatible nature makes it a trusted material for components in food, medical, and pharmaceutical manufacturing.

Ultimately, PTFE is chosen because it provides unwavering performance and longevity in environments that would compromise or destroy lesser materials.

Summary Table:

| Key Property | Key Benefit | Common Applications |

|---|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals | Gaskets, seals, linings for chemical processing |

| Temperature Stability | Performs from -200°C to +260°C | Aerospace components, industrial cooking equipment |

| Low Coefficient of Friction | Self-lubricating, non-stick quality | Bearings, bushings, low-friction coatings |

| Electrical Insulation | Stable dielectric constant across frequencies | High-frequency PCBs, RF electronics |

Ready to leverage the superior properties of PTFE for your critical components?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures your parts deliver unwavering performance and longevity in the most demanding environments.

Contact our experts today to discuss your custom PTFE fabrication needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application