In the chemical industry, the primary advantages of using Polytetrafluoroethylene (PTFE) valves are their exceptional chemical inertness, high-temperature stability, and inherent safety. Because PTFE is non-reactive with nearly all industrial chemicals, it prevents valve degradation and media contamination, ensuring both system integrity and product purity in the most aggressive environments.

The core challenge in chemical processing is safely containing and controlling corrosive materials. PTFE-lined valves solve this by creating a virtually impenetrable and non-reactive barrier, making them the default choice for applications where lesser materials would quickly fail.

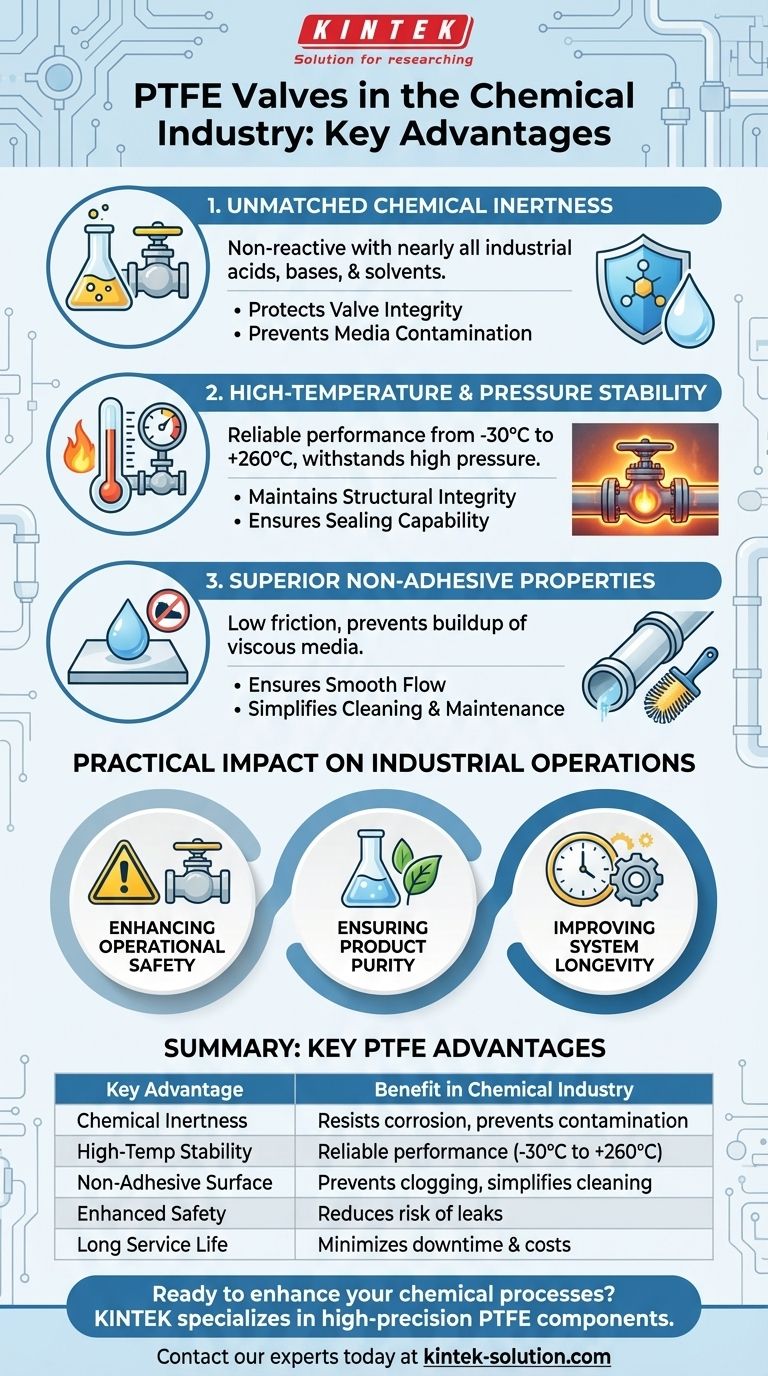

Why PTFE Sets the Standard for Chemical Handling

The unique molecular structure of PTFE gives it a combination of properties that are ideal for managing hazardous and high-purity substances. It is not just one feature, but the synergy of several, that makes it so effective.

Unmatched Chemical Inertness

PTFE is renowned for its resistance to corrosion and chemical attack. Its strong carbon-fluorine bonds make it non-reactive to the vast majority of acids, bases, and solvents used in industrial processes.

This inertness is critical for two reasons: it protects the valve's structural components from being eaten away by the media, and it prevents the valve material from leaching into and contaminating the product.

High-Temperature and Pressure Stability

Chemical reactions often involve high temperatures. PTFE performs reliably across a wide operating temperature range, typically from -30°C to +200°C, with some grades withstanding continuous service up to +260°C.

This thermal stability ensures the valve maintains its structural integrity and sealing capability without melting or degrading, even under harsh production conditions.

Superior Non-Adhesive Properties

PTFE has one of the lowest coefficients of friction of any solid material, giving it a powerful non-stick or non-adhesive surface.

This property is highly beneficial in valve applications as it prevents viscous or sticky media from building up on internal surfaces. This ensures smooth flow, minimizes the risk of clogging, and simplifies system cleaning and maintenance.

The Practical Impact on Industrial Operations

These material properties translate directly into tangible operational benefits, improving safety, longevity, and overall efficiency.

Enhancing Operational Safety

The most critical benefit is enhanced safety. By resisting chemical attack, PTFE linings and components drastically reduce the risk of dangerous leaks or catastrophic valve failure when handling aggressive substances.

Ensuring Product Purity

In industries like pharmaceuticals or specialty chemicals, product purity is non-negotiable. Because PTFE is inert and does not shed particles, it is an ideal material for wetted parts, ensuring the process media remains uncontaminated.

Improving System Longevity and Efficiency

Valves made with or lined with PTFE have a significantly longer service life in corrosive environments compared to traditional metal valves. This durability reduces the frequency of replacement and minimizes costly downtime for maintenance.

Understanding the Trade-offs

While PTFE's chemical performance is unparalleled, it is essential to approach it as an engineered material with specific characteristics, not a universal solution.

Mechanical Strength Limitations

Compared to solid metal alloys, PTFE is a softer material with lower tensile strength. In applications involving extremely high pressures, abrasive slurries, or significant physical stress, the mechanical limits of the valve design must be carefully evaluated.

Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion. Valve designers must account for this to ensure that tight seals and close tolerances are maintained across the entire operating temperature range of the application.

Making the Right Choice for Your Application

Selecting a PTFE valve should be based on the primary demands of your specific chemical process.

- If your primary focus is safety and product purity: PTFE is the superior choice for handling highly corrosive, hazardous, or high-purity media where material inertness is paramount.

- If your primary focus is long-term reliability: The exceptional durability of PTFE in chemical environments leads to a lower total cost of ownership by minimizing maintenance and replacement cycles.

- If your primary focus is process efficiency in high-temperature systems: PTFE's ability to maintain stability at elevated temperatures while preventing material buildup ensures consistent and reliable operation.

Ultimately, specifying PTFE valves is a strategic decision to ensure safety, preserve product quality, and maximize the operational lifespan of your critical chemical systems.

Summary Table:

| Key Advantage | Benefit in Chemical Industry |

|---|---|

| Chemical Inertness | Resists corrosion and prevents product contamination. |

| High-Temperature Stability | Reliable performance from -30°C to +260°C. |

| Non-Adhesive Surface | Prevents clogging and simplifies cleaning. |

| Enhanced Safety | Reduces risk of leaks with aggressive substances. |

| Long Service Life | Minimizes downtime and replacement costs. |

Ready to enhance the safety and efficiency of your chemical processes?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom valves, tailored for the demanding environments of the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your systems achieve maximum reliability and product purity.

Contact our experts today to discuss your specific requirements, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials