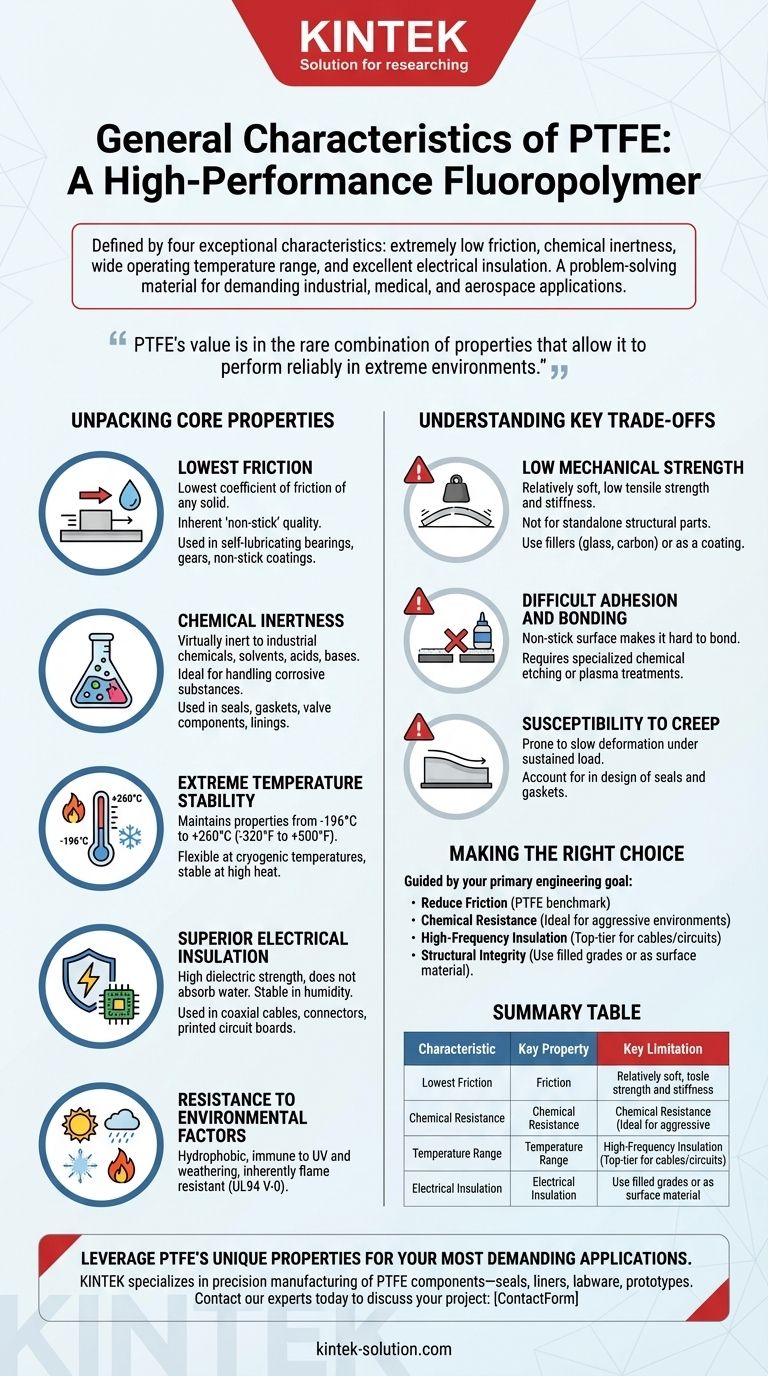

In essence, Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer defined by four exceptional characteristics: an extremely low coefficient of friction, near-total chemical inertness, a very wide operating temperature range, and excellent electrical insulation. These properties make it a problem-solving material for some of the most demanding industrial, medical, and aerospace applications.

PTFE's value isn't just in one standout feature, but in the rare combination of properties that allow it to perform reliably in extreme environments where nearly all other materials would fail. Understanding its limitations is just as critical as appreciating its strengths.

Unpacking the Core Properties of PTFE

To determine if PTFE is the right choice for your project, it's essential to understand the practical implications of its primary characteristics.

The Lowest Friction of Any Solid

PTFE possesses the lowest known coefficient of friction of any solid material. This gives it a unique, exceptionally slippery or "non-stick" quality.

This property is not just a surface treatment; it is an inherent part of the material. It allows PTFE to be used in applications requiring smooth, low-resistance movement, such as self-lubricating bearings, gears, and non-stick coatings.

Unmatched Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of industrial chemicals, solvents, acids, and bases. This makes it an ideal material for handling and containing highly corrosive substances.

Its applications in this area include seals, gaskets, valve components, and linings for vessels and pipes used in chemical processing plants.

Extreme Temperature Stability

PTFE maintains its properties across an exceptionally broad temperature spectrum, typically cited as -196°C to +260°C (-320°F to +500°F).

It remains flexible even at cryogenic temperatures and does not degrade at high heat, with a melting point well over 300°C. This stability allows it to be used in environments ranging from deep space to high-temperature industrial processes.

Superior Electrical Insulation

PTFE is an outstanding electrical insulator with a high dielectric strength. It resists high voltages and does not absorb water, ensuring its insulating properties remain stable even in humid conditions.

This makes it a top-tier material for high-frequency applications, such as insulation for coaxial cables, connectors, and printed circuit boards used in telecommunications and aerospace.

Resistance to Environmental Factors

Beyond its core features, PTFE is highly resistant to environmental degradation. It is hydrophobic (repels water), immune to UV radiation and weathering, and is inherently flame resistant with a UL94 V-0 rating.

Understanding the Key Trade-offs

No material is perfect. To use PTFE effectively, you must be aware of its inherent limitations, which often stem directly from its strengths.

Low Mechanical Strength

PTFE is a relatively soft material. It has low tensile strength, stiffness, and abrasion resistance compared to other engineering plastics like nylon or PEEK.

It is generally not suitable for standalone structural components that must bear significant mechanical loads. This is often overcome by using fillers (like glass or carbon) or by applying PTFE as a coating on a stronger substrate.

Difficult Adhesion and Bonding

The same non-stick property that makes PTFE so valuable also makes it extremely difficult to bond to other materials. Its surface is non-adhesive, requiring specialized chemical etching or plasma treatments to prepare it for gluing.

Susceptibility to Creep

As a soft material, PTFE is prone to "creep," which is the tendency to slowly deform over time when under a sustained load. This must be accounted for in the design of components like seals and gaskets to ensure long-term performance.

Making the Right Choice for Your Application

Your final decision should be guided by your primary engineering goal.

- If your primary focus is reducing friction: PTFE is the benchmark material for non-stick surfaces, low-drag coatings, and self-lubricating bearings.

- If your primary focus is chemical resistance: It is an ideal choice for seals, linings, and fluid-handling components in chemically aggressive environments.

- If your primary focus is high-frequency electrical insulation: Its stable dielectric properties make it a top-tier material for high-performance cables and circuit boards.

- If your primary focus is structural integrity: You should consider filled grades of PTFE or use it as a surface material rather than as a standalone load-bearing part.

By balancing its remarkable strengths against its specific weaknesses, you can leverage PTFE to solve your most difficult material science challenges.

Summary Table:

| Characteristic | Key Property | Key Limitation |

|---|---|---|

| Friction | Lowest coefficient of friction of any solid | Low mechanical strength and abrasion resistance |

| Chemical Resistance | Virtually inert to most chemicals | Difficult to bond/adhere to other materials |

| Temperature Range | Stable from -196°C to +260°C | Prone to creep under sustained load |

| Electrical Insulation | Excellent dielectric strength, stable in humidity | Not suitable for structural, load-bearing parts |

Leverage PTFE's Unique Properties for Your Most Demanding Applications

PTFE's combination of extreme chemical resistance, low friction, and thermal stability makes it ideal for solving complex challenges in the semiconductor, medical, laboratory, and industrial sectors.

KINTEK specializes in precision manufacturing of PTFE components—from custom seals, liners, and labware to complex prototypes and high-volume production runs. We ensure your parts meet exact specifications for performance in critical environments.

Ready to solve your material challenge? Contact our experts today to discuss your project requirements and receive a custom solution.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What alternatives exist for PTFE in consumer products? Discover Safer Options for Cookware, Clothing & Cosmetics

- What benefits does Teflon coating offer in chemical manufacturing? Boost Equipment Lifespan & Purity

- How does graphite-filled PTFE perform? A Guide to Superior Self-Lubricating Components

- What should consumers be cautious about regarding PTFE? The Hidden Risks of 'Forever Chemicals'

- What are the key differences between PTFE and RPTFE? Choose the Right Material for Your Application

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What are some unique properties of PTFE that make it valuable for various applications? The Ultimate Guide to PTFE's Elite Performance

- What are the properties of pure PTFE material? Unlock Superior Chemical & Thermal Performance