In short, fillers are added to PTFE to overcome its inherent weaknesses, primarily its softness, poor wear resistance, and tendency to deform under load (a phenomenon known as "creep"). By incorporating materials like glass, carbon, or stainless steel, virgin PTFE is transformed into a robust engineering composite with significantly improved mechanical and thermal properties.

The core purpose of using fillers is to enhance the performance of PTFE in demanding applications where the virgin material would fail. Fillers act as a reinforcement, improving strength, wear resistance, and thermal stability, thereby expanding PTFE's utility far beyond its base capabilities.

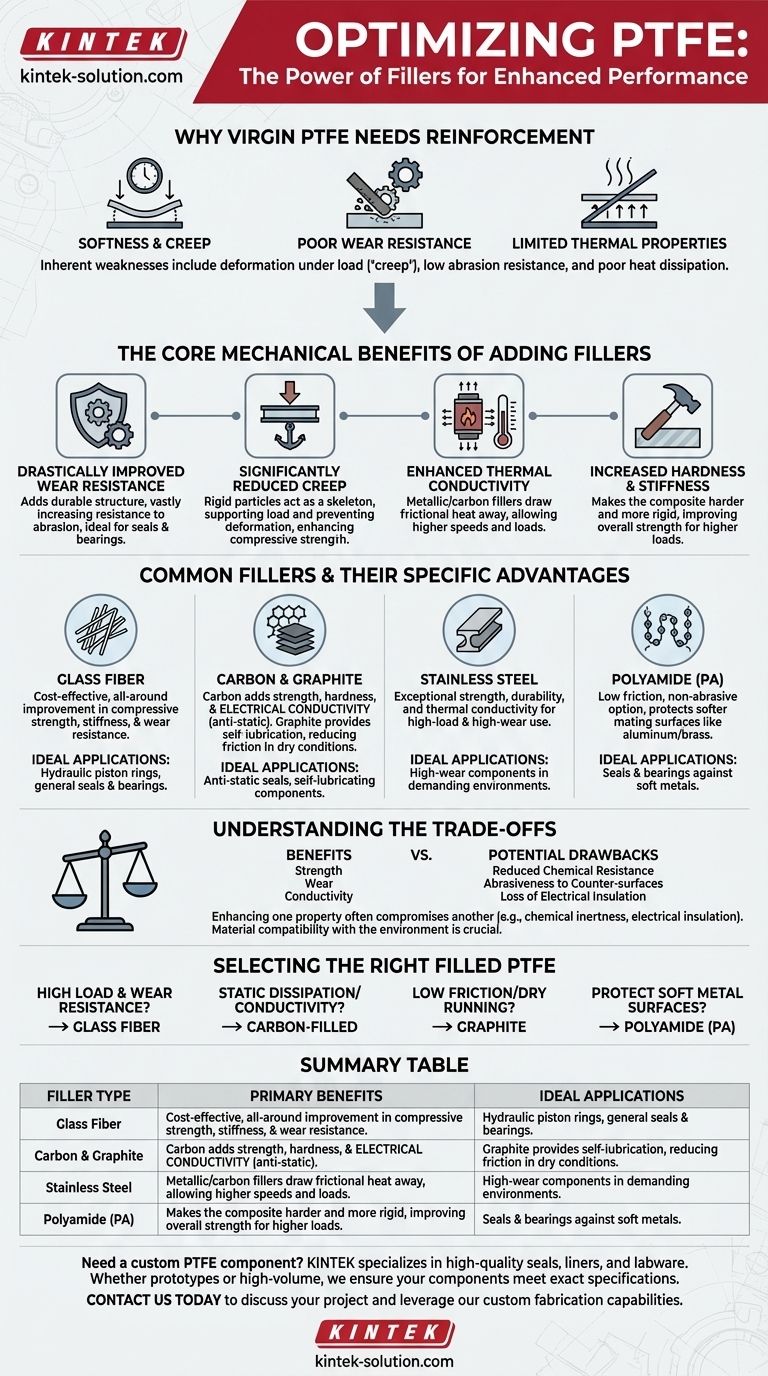

Why Virgin PTFE Needs Reinforcement

While renowned for its extremely low friction and broad chemical resistance, virgin PTFE has significant mechanical limitations that restrict its use.

The Challenge of "Creep"

PTFE is a relatively soft material. Under a sustained load, even at room temperature, it will slowly deform or "cold flow." This makes it unsuitable for components that must maintain precise dimensions under pressure.

Poor Wear Resistance

Despite its slipperiness, virgin PTFE abrades easily. In dynamic applications like bearings or seals, it can wear away quickly, leading to premature failure.

Limited Thermal Properties

PTFE is an excellent thermal insulator. In high-speed applications, this prevents the dissipation of frictional heat, which can cause the material to soften and fail.

The Core Mechanical Benefits of Adding Fillers

Fillers are chosen to systematically address these weaknesses, creating a compound tailored for a specific operational environment.

Drastically Improved Wear Resistance

Fillers add a durable structure to the soft PTFE matrix, vastly increasing its resistance to abrasion. This is one of the most common reasons for using a filled compound, especially in seals and bearings.

Significantly Reduced Creep

The rigid particles of the filler material act like a skeleton within the PTFE, supporting the load and preventing the polymer from deforming. This leads to much higher compressive strength and dimensional stability.

Enhanced Thermal Conductivity

Many fillers, especially metallic or carbon-based ones, are more thermally conductive than PTFE. They help draw frictional heat away from the operating surface, allowing the component to run at higher speeds and loads without overheating.

Increased Hardness and Stiffness

Adding a filler material makes the resulting composite harder and more rigid than virgin PTFE. This improves the material's overall strength and ability to handle higher loads.

Common Fillers and Their Specific Advantages

The choice of filler directly influences the final properties of the compound.

Glass Fiber

Glass is the most common and cost-effective filler. It provides an excellent all-around improvement in compressive strength, stiffness, and wear resistance, making it ideal for applications like hydraulic piston rings.

Carbon and Graphite

Carbon significantly increases compressive strength, hardness, and wear resistance. Critically, it also adds electrical conductivity, making it suitable for anti-static applications.

Graphite is often added alongside carbon or glass. It provides self-lubricating properties, reducing the coefficient of friction and improving wear characteristics, especially in dry-running conditions.

Stainless Steel

For high-load and high-wear applications, stainless steel fillers provide exceptional strength and durability. They also improve the thermal conductivity of the compound.

Polyamide (PA)

Polyamide is a polymer filler known for its low friction coefficient. It is a non-abrasive option, making it ideal for applications running against softer metal surfaces like stainless steel, brass, or aluminum.

Understanding the Trade-offs

Enhancing one property of PTFE with a filler almost always comes at the expense of another. This is the critical trade-off in material selection.

Compromised Chemical Resistance

The primary trade-off is a reduction in chemical inertness. The filler material may be attacked by chemicals that virgin PTFE would easily resist. The filler must be compatible with the intended service environment.

Potential for Abrasion

Aggressive fillers like glass can be abrasive to softer counter-surfaces. In such cases, a less abrasive filler like graphite or polyamide might be a better choice.

Loss of Electrical Insulation

Virgin PTFE is an excellent electrical insulator. The addition of conductive fillers like carbon or stainless steel will eliminate this property, which may or may not be desirable depending on the application.

Selecting the Right Filled PTFE for Your Application

The optimal choice is always dictated by the primary demands of your specific use case.

- If your primary focus is high load and general-purpose wear resistance: Glass-filled PTFE is the most common and economical choice.

- If your primary focus is static dissipation or electrical conductivity: Carbon-filled PTFE is the standard material for these requirements.

- If your primary focus is low friction in dry or non-lubricated conditions: A compound containing graphite will provide the necessary self-lubricating properties.

- If your primary focus is running against soft metal surfaces like aluminum: A non-abrasive filler like polyamide is the safest option to prevent damage to the mating component.

Ultimately, fillers elevate PTFE from a specialty polymer to a versatile engineering workhorse, but success requires a clear understanding of how each additive modifies the material to meet a specific challenge.

Summary Table:

| Filler Type | Primary Benefits | Ideal Applications |

|---|---|---|

| Glass Fiber | Cost-effective, improves compressive strength, stiffness, and wear resistance | Hydraulic piston rings, general-purpose seals and bearings |

| Carbon/Graphite | Increases hardness, wear resistance, and adds electrical conductivity | Anti-static seals, components requiring self-lubrication |

| Stainless Steel | Exceptional strength, durability, and thermal conductivity for high-load applications | High-wear components in demanding environments |

| Polyamide (PA) | Non-abrasive, low friction coefficient for use with soft metal surfaces | Seals and bearings running against aluminum, brass, or stainless steel |

Need a custom PTFE component that balances performance with precision? KINTEK specializes in manufacturing high-quality PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise in filled PTFE compounds ensures your components meet exact specifications for wear resistance, thermal stability, and chemical compatibility. Contact us today to discuss your project and leverage our custom fabrication capabilities!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- How does the chemical resistance of PTFE oil seals benefit their use? Ensure Leak-Free Reliability in Harsh Chemical Environments

- What are the key advantages of PTFE gaskets? Superior Sealing for Harsh Chemical & Thermal Environments

- What are the standard sheet sizes for PTFE? Optimize Your Material Selection

- What are the advantages of using PTFE as the material for rotary shaft lip seals? Achieve Unmatched Reliability in Extreme Conditions

- How does the method of PTFE molding affect the performance of the parts produced? Choose the Right Process for Optimal Strength.

- What are some common applications of PTFE balls? Essential Uses in Chemical & Low-Friction Systems

- What makes ePTFE suitable for filtration applications? Unlock Superior Performance for Demanding Environments

- What are the standard sizes available for PTFE wear strips and bands? Custom Sizes for Optimal Performance