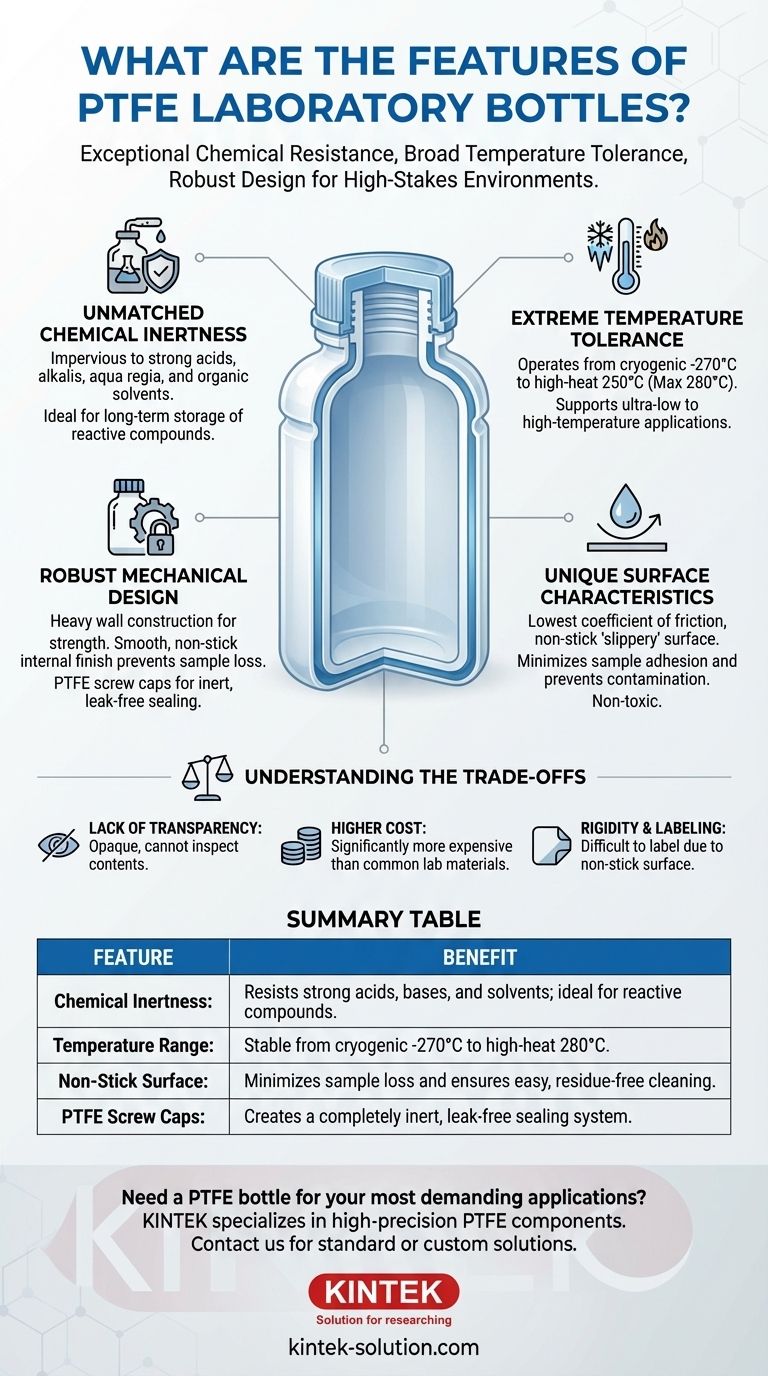

In short, PTFE laboratory bottles are defined by their exceptional chemical resistance, an extremely broad temperature tolerance, and robust physical design. They are engineered for high-stakes laboratory environments where sample purity and container integrity under harsh conditions are non-negotiable.

The core reason to choose a PTFE bottle is for its near-total chemical inertness and stability across a vast temperature range, from cryogenic lows to high-heat applications. It is a specialized tool for tasks that would cause standard glass or plastic labware to fail.

Unpacking the Core Properties of PTFE

The unique combination of features in Polytetrafluoroethylene (PTFE) makes it a high-performance material for demanding scientific work. Understanding these properties helps clarify why it's chosen for specific applications.

Unmatched Chemical Inertness

PTFE is virtually impervious to chemical attack. It is highly resistant to the most aggressive substances used in a lab.

This includes strong acids, alkalis, aqua regia, and a wide array of organic solvents. This makes PTFE bottles ideal for long-term storage of reactive compounds and for conducting dissolutions or digestions.

Extreme Temperature Tolerance

The operational temperature range for PTFE is remarkably wide. It remains functional and stable in conditions that would destroy most other materials.

These bottles can be used continuously from cryogenic temperatures of -270°C up to 250°C (with a maximum use temperature of around 280°C). This versatility supports applications from ultra-low temperature storage to high-temperature reactions.

Robust Mechanical Design

PTFE lab bottles are built for reliability and to prevent contamination. They typically feature a heavy wall construction that provides high strength and durability.

The internal finish is exceptionally smooth and non-stick, which helps prevent sample loss and ensures easy, residue-free cleaning. Critically, the screw caps are also made of PTFE, creating a completely inert and leak-free sealing system.

Unique Surface Characteristics

PTFE possesses the lowest coefficient of friction of any known solid, making it famously "slippery" or non-stick.

This property is crucial for quantitative analysis, as it minimizes the chance of your sample adhering to the bottle's surface. Furthermore, the material is non-toxic and biocompatible, ensuring it will not leach contaminants into the stored substance.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not the default choice for every application. Understanding its limitations is key to using it effectively.

Lack of Transparency

PTFE is an opaque material. Unlike glass or plastics like polycarbonate, you cannot visually inspect the contents of a PTFE bottle. This makes it difficult to quickly assess volume or observe reactions.

Higher Cost

As a high-performance polymer, PTFE is significantly more expensive than common lab materials like glass, polyethylene (PE), or polypropylene (PP). Its use is typically justified by the necessity for extreme chemical or thermal resistance.

Rigidity and Labeling

The same non-stick surface that prevents sample adhesion also makes the bottle difficult to label. Standard adhesive labels will not stick, requiring alternative methods for marking. While strong, its flexibility and impact resistance differ from other common lab plastics.

Making the Right Choice for Your Application

Selecting the right bottle material comes down to the specific demands of your work.

- If your primary focus is storing highly corrosive chemicals: PTFE is the safest and most reliable choice, offering unmatched resistance to acids, bases, and solvents.

- If your primary focus is working at extreme temperatures: PTFE's ability to perform in both cryogenic and high-heat conditions makes it one of the few viable options.

- If your primary focus is trace analysis or sample purity: The inert, non-stick surface of PTFE minimizes analyte adhesion and prevents container-leached contamination.

- If your primary focus is general, room-temperature storage of benign reagents: A more cost-effective material like glass or HDPE is likely a more practical choice.

Ultimately, choosing a PTFE bottle is an investment in certainty for your most demanding applications.

Summary Table:

| Feature | Benefit |

|---|---|

| Chemical Inertness | Resists strong acids, bases, and solvents; ideal for reactive compounds. |

| Temperature Range | Stable from cryogenic -270°C to high-heat 280°C. |

| Non-Stick Surface | Minimizes sample loss and ensures easy, residue-free cleaning. |

| PTFE Screw Caps | Creates a completely inert, leak-free sealing system. |

Need a PTFE bottle for your most demanding applications?

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We ensure your samples are protected with containers that offer unmatched chemical resistance and thermal stability.

Whether you require a standard design or a custom-fabricated solution from prototype to high-volume production, our expertise guarantees quality and reliability. Contact us today to discuss your specific needs and let us provide the certainty your work demands.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How do Teflon membranes enhance chemical resistance in laboratory equipment? Maximize Purity and Durability

- What advantages do PTFE syringe filters offer in laboratory settings? Unmatched Chemical Resistance & Purity

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What are the applications of PTFE-lined bottle caps? Ensure Ultimate Purity and Chemical Resistance

- What are the primary uses of PTFE filters? Achieve Pure, Sterile Filtration for Aggressive Chemicals

- How are PTFE stirrers and shafts typically constructed for industrial use? Choose the Right Method for Your Process

- What are the main materials considered for laboratory impellers? PTFE vs. Stainless Steel

- Why is PTFE particularly valuable in laboratory settings? Achieve Unmatched Purity and Safety