In short, the primary disadvantages of Reinforced PTFE (RPTFE) stem directly from its reinforcing fillers. While these fillers enhance mechanical properties like strength and creep resistance over virgin PTFE, they introduce significant drawbacks, including increased cost, reduced chemical compatibility, potential for contamination, and fabrication challenges.

The core issue with RPTFE is not a failure of the base PTFE material, but a series of trade-offs introduced by the filler. You gain mechanical strength but sacrifice some of the key benefits of pure PTFE, such as its broad chemical inertness and compliance with purity standards.

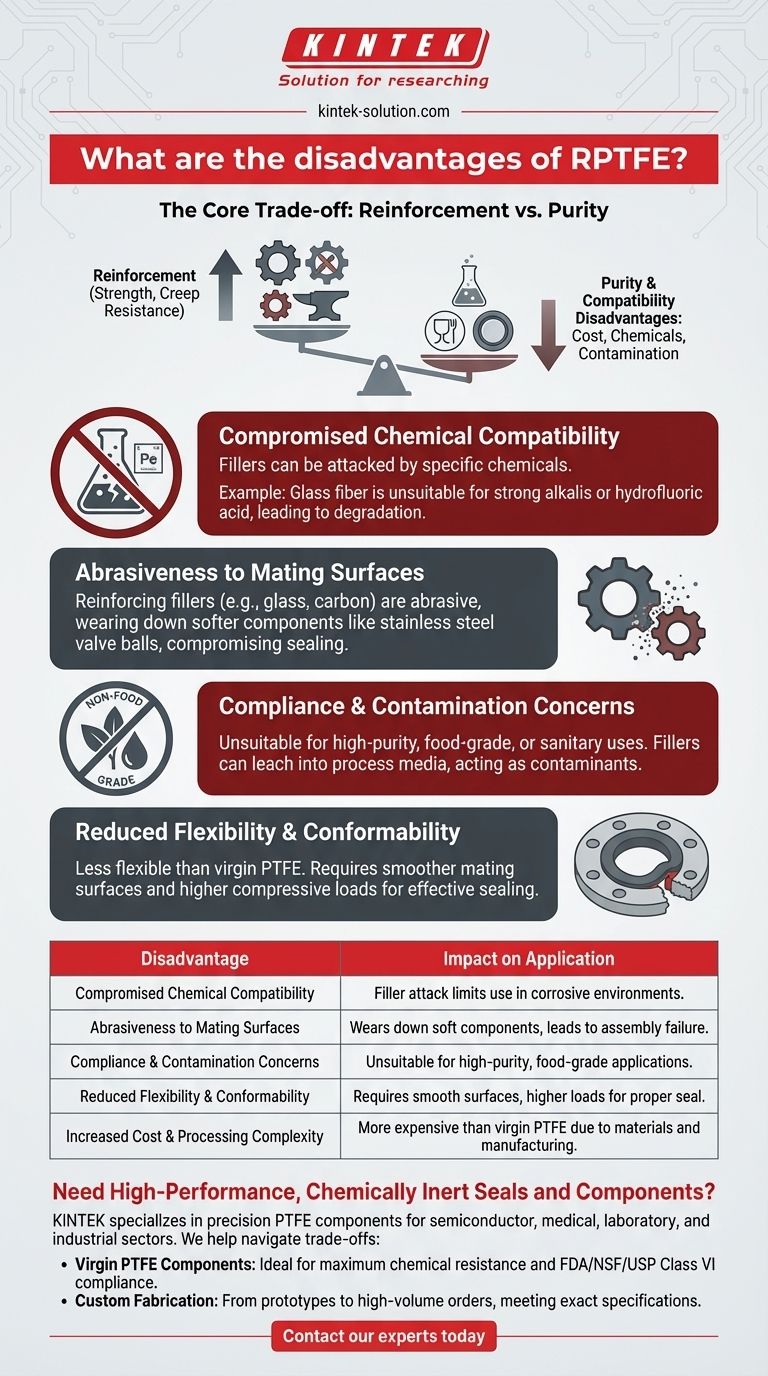

The Core Trade-off: Reinforcement vs. Purity

To understand the disadvantages of RPTFE, you must first understand its composition. RPTFE is simply Polytetrafluoroethylene (PTFE) with a filler material, such as glass fiber, carbon, or stainless steel, mixed in. These fillers are the source of RPTFE's limitations.

Increased Cost and Processing Complexity

RPTFE is more expensive than virgin PTFE. This is due to the cost of the filler material itself and the more complex manufacturing process required to ensure a homogenous blend.

This complexity can also affect the consistency and quality control of mass-produced parts, requiring more stringent oversight than for virgin PTFE.

Compromised Chemical Compatibility

While the PTFE base remains highly inert, the filler material can be attacked by chemicals that would not affect pure PTFE.

For example, glass-reinforced RPTFE is unsuitable for strong alkalis or hydrofluoric acid, which would degrade the glass fibers and lead to premature failure of the seal or component.

Reduced Flexibility and Conformability

The addition of rigid fillers makes RPTFE a harder, less flexible material. Virgin PTFE is soft and easily conforms to surface imperfections, creating a highly effective seal.

RPTFE is less forgiving. It requires smoother mating surfaces and higher compressive loads to achieve a proper seal, making it less effective in applications with rough or irregular flanges.

Critical Performance Limitations

The mechanical changes in RPTFE create specific limitations that are critical to consider during the design phase.

Abrasiveness to Mating Surfaces

Reinforcing fillers, particularly glass fiber and carbon, are abrasive. Over time, an RPTFE component can wear down softer mating surfaces, such as stainless steel valve balls or stems.

This wear can compromise the sealing performance of the entire assembly, not just the RPTFE part itself, leading to costly damage and downtime.

Compliance and Contamination Concerns

The presence of fillers almost always disqualifies RPTFE from use in high-purity, food-grade, or sanitary applications.

Fillers can leach into the process media, acting as a contaminant. For this reason, materials like virgin PTFE, which can be manufactured to meet FDA, NSF, and USP Class VI standards, are the required choice for these industries.

Difficulty with Adhesion and Bonding

Like virgin PTFE, RPTFE has extremely low surface energy, making it nearly impossible to bond using conventional cements or adhesives.

While this is a property of the base PTFE, it's an important disadvantage to remember. The material cannot be easily repaired or integrated into assemblies that rely on bonding.

Making the Right Choice for Your Application

Choosing between RPTFE and virgin PTFE requires a clear understanding of your primary operational goal.

- If your primary focus is high pressure and temperature resistance: RPTFE is often the superior choice, provided the filler material is fully compatible with your process chemistry.

- If your primary focus is broad chemical inertness or food safety: Virgin PTFE is the only reliable option to ensure purity and compliance.

- If your primary focus is cost-effectiveness or sealing on imperfect surfaces: Virgin PTFE's lower cost and superior flexibility make it the better starting point.

Ultimately, selecting the right material depends on a careful evaluation of the trade-offs between mechanical performance and chemical purity.

Summary Table:

| Disadvantage | Impact on Application |

|---|---|

| Compromised Chemical Compatibility | Filler materials can be attacked by chemicals, limiting use in corrosive environments. |

| Abrasiveness to Mating Surfaces | Fillers like glass fiber can wear down softer components, leading to assembly failure. |

| Compliance & Contamination Concerns | Fillers can leach out, making RPTFE unsuitable for high-purity, food-grade, or sanitary uses. |

| Reduced Flexibility & Conformability | Requires smoother mating surfaces and higher compressive loads to achieve a proper seal. |

| Increased Cost & Processing Complexity | More expensive than virgin PTFE due to filler materials and complex manufacturing. |

Need High-Performance, Chemically Inert Seals and Components?

Choosing the right PTFE material is critical for your application's success. The disadvantages of RPTFE highlight the importance of material purity and compatibility.

KINTEK specializes in precision PTFE components for the semiconductor, medical, laboratory, and industrial sectors. We help you navigate these trade-offs by offering:

- Virgin PTFE Components: Ideal for maximum chemical resistance and compliance with FDA, NSF, and USP Class VI standards.

- Custom Fabrication: From prototypes to high-volume orders, we ensure your parts meet exact specifications for performance and purity.

Don't let material limitations compromise your project. Contact our experts today to discuss your requirements and get a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the primary applications of PTFE? Unlocking High-Performance Solutions

- What are some key properties of PTFE? Discover the High-Performance Polymer for Extreme Applications

- What is the temperature resistance of Teflon? Master Its Performance from -200°C to 260°C

- Why can't PTFE be processed using conventional polymer techniques? Discover the Sintering Solution

- How does PTFE perform when exposed to different types of water? Unmatched Chemical Resistance in Any Aqueous Environment

- What is the relationship between PTFE and Teflon? A Guide to the Material vs. the Brand Name

- What makes PTFE plastic uniquely versatile across industries? The 4 Key Properties Explained

- What are the temperature properties of PTFE? From -268°C to 260°C, a Guide to Extreme Thermal Stability