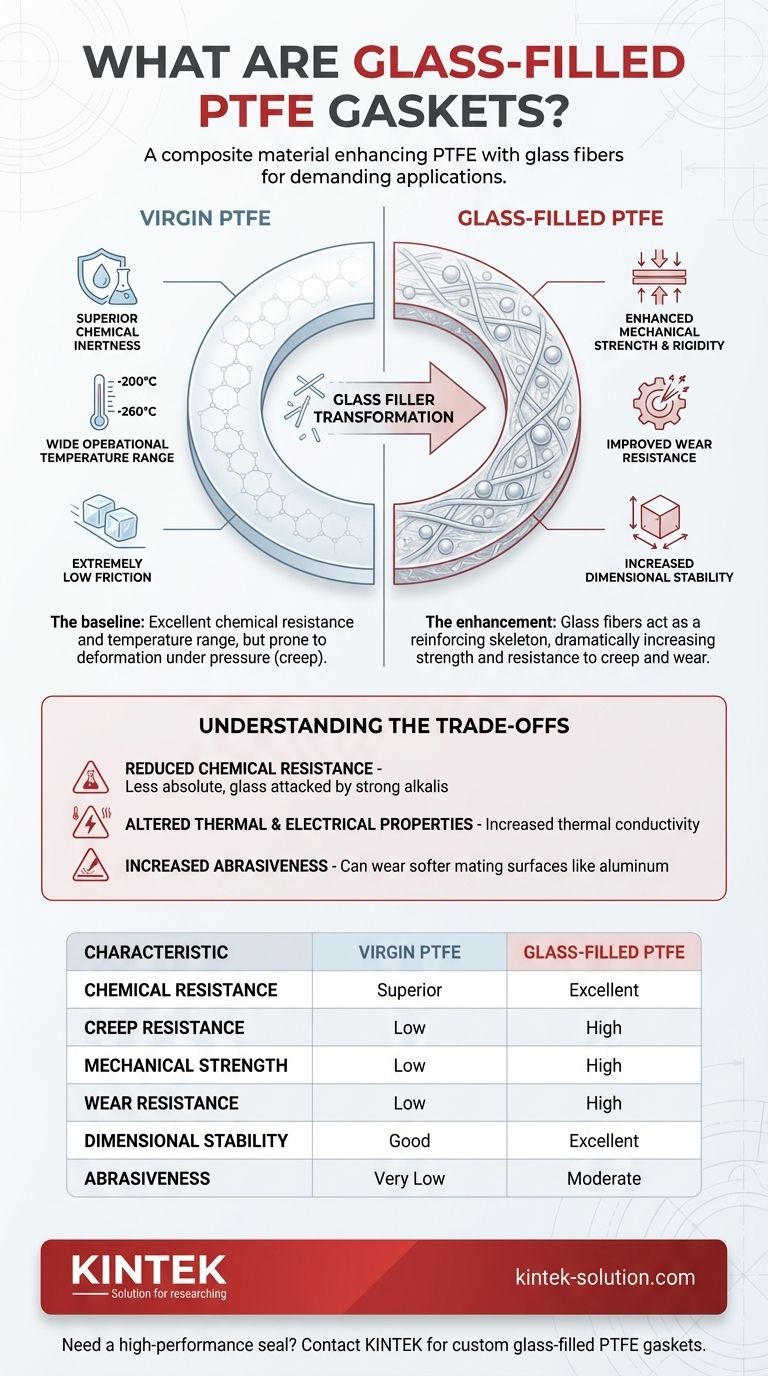

At its core, a glass-filled PTFE gasket is a composite material that enhances standard Polytetrafluoroethylene (PTFE) with glass fibers or microspheres. This addition significantly improves the gasket's mechanical properties, specifically its strength, wear resistance, and ability to resist deformation under load, making it suitable for more demanding applications.

The fundamental trade-off is simple: you are sacrificing some of the absolute chemical purity and electrical insulation of virgin PTFE to gain a significant boost in mechanical strength, rigidity, and dimensional stability, especially for high-pressure and high-temperature sealing.

The PTFE Foundation: Baseline Properties

To understand the benefits of glass fillers, we must first establish the inherent characteristics of virgin PTFE. It is a remarkable polymer known for a unique combination of properties.

Superior Chemical Inertness

PTFE is one of the most non-reactive substances known. It resists attack from the vast majority of industrial chemicals, acids, and bases, making it a default choice for chemically aggressive environments.

Wide Operational Temperature Range

Standard PTFE performs exceptionally well across a massive temperature spectrum. It remains reliable and flexible from cryogenic temperatures (-200°C) up to a continuous service temperature of +260°C.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" quality is critical in applications where self-lubrication is required.

How Glass Fillers Transform PTFE

Adding glass as a filler material directly addresses the primary weakness of virgin PTFE: its tendency to deform under pressure, a phenomenon known as creep or cold flow.

Enhanced Mechanical Strength and Rigidity

The glass fibers act as a reinforcing skeleton within the soft PTFE matrix. This dramatically increases the material's compressive strength and rigidity, preventing the gasket from being squeezed out of a flange under high bolt loads.

Improved Wear Resistance

The hardness of the glass particles significantly improves the material's resistance to abrasive wear. This makes it far more durable in dynamic or high-vibration systems where surfaces may rub against the gasket.

Increased Dimensional Stability

By reinforcing the PTFE, glass fillers reduce the material's tendency to expand or contract with temperature changes. This dimensional stability is crucial for maintaining a reliable seal in applications with fluctuating thermal cycles.

Understanding the Trade-offs

Introducing a filler material is not without consequences. While you gain mechanical performance, you must be aware of the compromises.

Reduced Chemical Resistance

While still excellent, the chemical resistance of glass-filled PTFE is not as absolute as virgin PTFE. The glass filler itself can be attacked by certain aggressive media, such as strong alkalis or hydrofluoric acid.

Altered Thermal and Electrical Properties

Virgin PTFE is an excellent thermal and electrical insulator. The addition of glass fibers increases thermal conductivity, meaning it will transfer heat more readily than pure PTFE. This can be a benefit or a drawback depending on the application's need for insulation. Its electrical properties may also be slightly altered.

Increased Abrasiveness

The hard glass fibers that provide wear resistance can also be abrasive to softer mating surfaces, such as those made from aluminum or brass. This must be considered when designing the flange or sealing surface.

Making the Right Choice for Your Application

Selecting the correct gasket material requires matching its properties to your primary operational goal.

- If your primary focus is ultimate chemical purity and inertness: Stick with virgin PTFE, as it offers the most comprehensive chemical resistance with no risk of filler contamination.

- If your primary focus is sealing under high pressure or temperature: Glass-filled PTFE is the superior choice due to its excellent resistance to creep and deformation.

- If your primary focus is durability in a dynamic or abrasive system: The significantly improved wear resistance of glass-filled PTFE makes it the clear winner.

- If your mating surfaces are soft or easily damaged: Carefully evaluate virgin PTFE first to avoid potential abrasion from the glass filler.

Ultimately, choosing glass-filled PTFE is a strategic decision to enhance the mechanical integrity of a seal in demanding service conditions.

Summary Table:

| Characteristic | Virgin PTFE | Glass-Filled PTFE |

|---|---|---|

| Chemical Resistance | Superior (Highly Inert) | Excellent (Slightly Reduced) |

| Creep/Deformation Resistance | Low | High |

| Mechanical Strength & Rigidity | Low | High |

| Wear & Abrasion Resistance | Low | High |

| Dimensional Stability | Good | Excellent |

| Abrasiveness to Mating Surfaces | Very Low | Moderate |

Need a high-performance seal that can handle pressure, temperature, and wear?

At KINTEK, we specialize in precision-manufactured PTFE components, including custom glass-filled PTFE gaskets. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures you get a component that delivers:

- Enhanced Durability: Superior resistance to creep and abrasion for longer service life.

- Reliable Performance: Consistent sealing under high pressure and temperature fluctuations.

- Custom Fabrication: Tailored solutions from prototypes to high-volume production runs.

Let us help you solve your toughest sealing challenges. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some common variations and grades of PTFE used in seals? Optimize Performance with the Right Material

- What makes PTFE a popular choice for sealing applications? Discover Its Superior Chemical & Temperature Resistance

- Why are envelope gaskets also called 'encased' or 'enclosed' PTFE seals? The Key to Superior Chemical Sealing

- What is the chemical formula and material of PTFE Disk? Unlock the Power of C₂F₄ Polymer

- Why is tool selection important in the CNC machining of PTFE parts? Achieve Precision and Quality

- Where are thick PTFE washers (2mm – 4mm) typically used? For High-Pressure Sealing & Electrical Insulation

- How is surface preparation performed for PTFE coating application? Achieve Unbreakable Adhesion for Your Components

- What are the common grades of PTFE used in machining? Choose the Right Grade for Your Application