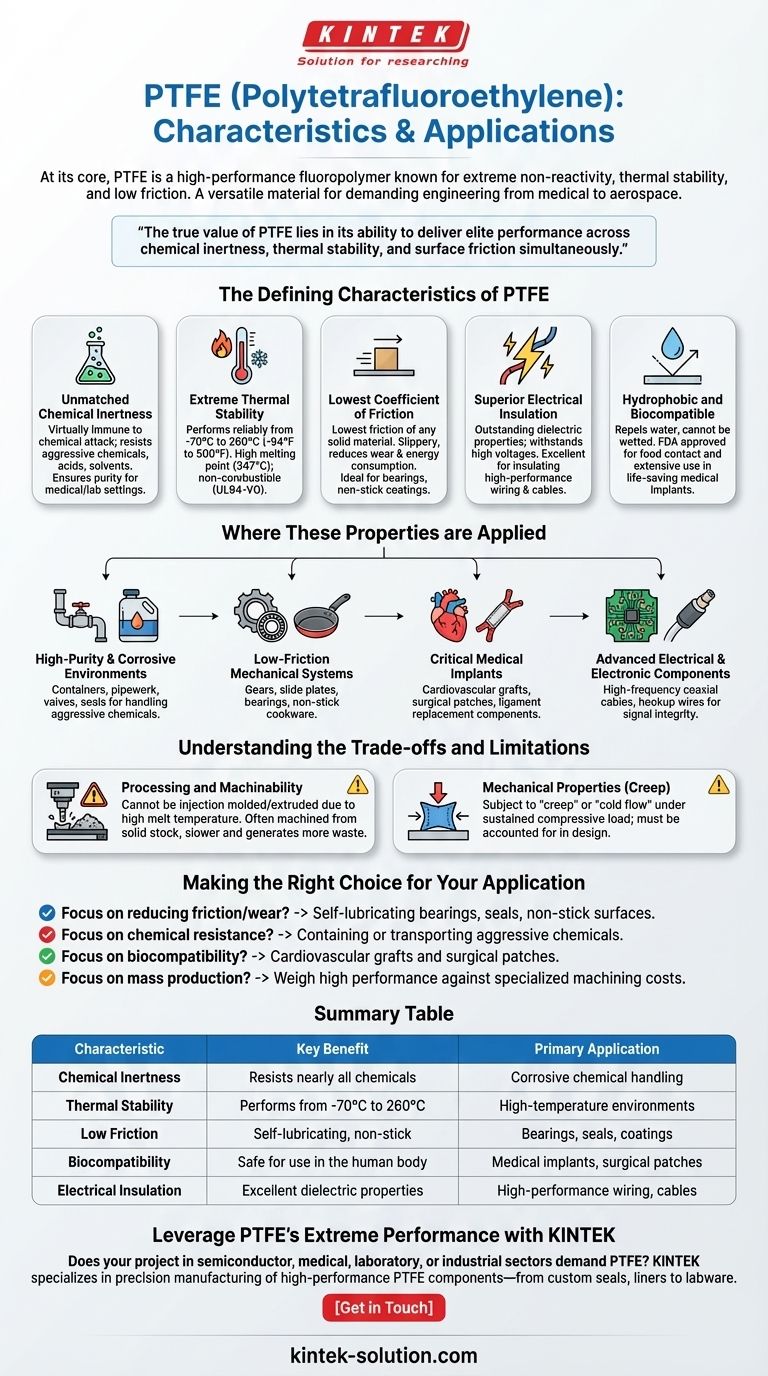

At its core, Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer best known for its extreme non-reactivity, thermal stability, and incredibly low coefficient of friction. This unique combination of properties makes it one of the most versatile and valuable materials for demanding engineering applications, from medical implants to aerospace components.

The true value of PTFE lies not in a single characteristic, but in its rare ability to deliver elite performance across three critical areas simultaneously: chemical inertness, thermal stability, and surface friction. This makes it the material of choice for extreme environments where others would fail.

The Defining Characteristics of PTFE

To understand PTFE's wide range of applications, you must first understand the fundamental properties that set it apart from nearly all other polymers.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack. It is highly resistant to a wide range of industrial chemicals, acids, and solvents, making it invaluable for handling corrosive materials.

This non-reactive nature also ensures its purity, a critical factor in medical and laboratory settings.

Extreme Thermal Stability

PTFE performs reliably across an exceptionally broad temperature range, typically from -70°C to 260°C (-94°F to 500°F).

It also has a very high melting point of around 347°C (657°F) and is non-combustible, with a UL94-VO flame rating, meaning it does not promote the spread of flames.

The Lowest Coefficient of Friction

PTFE has the lowest coefficient of friction of any known solid material, making it one of the most "slippery" substances in existence.

This property is central to its use in applications where reducing wear, friction, and energy consumption is paramount, such as in bearings or non-stick coatings.

Superior Electrical Insulation

PTFE possesses outstanding dielectric properties, meaning it is an excellent electrical insulator that can withstand high voltages.

This makes it an ideal material for insulating high-performance wiring and cables, especially in computer and aerospace applications.

Hydrophobic and Biocompatible

The material is hydrophobic, meaning it repels water and cannot be wetted. It is also highly biocompatible, as the human body does not react to its presence.

This combination of inertness and purity has led to its FDA approval for food contact and its extensive use in life-saving medical implants.

Where These Properties are Applied

The unique characteristics of PTFE directly translate into its use in some of the world's most critical and high-performance applications.

In High-Purity and Corrosive Environments

Because it is so non-reactive, PTFE is used to create containers, pipework, valves, and seals for handling the most aggressive and corrosive chemicals in processing plants.

For Low-Friction Mechanical Systems

Its incredibly low friction surface makes it the ideal choice for gears, slide plates, and bearings that operate without external lubrication. This is also the principle behind its most famous consumer application: non-stick cookware.

In Critical Medical Implants

PTFE's biocompatibility allows it to be used inside the human body with minimal risk of rejection. Common applications include cardiovascular grafts to repair blood vessels, surgical patches, and components for ligament replacement.

For Advanced Electrical and Electronic Components

The excellent insulating properties of PTFE are essential for manufacturing high-frequency coaxial cables and hookup wires where signal integrity and safety are critical.

Understanding the Trade-offs and Limitations

While its properties are exceptional, PTFE is not a universally perfect material. Its limitations are primarily related to its processing and mechanical behavior.

Processing and Machinability

PTFE's high melt temperature and viscosity prevent it from being processed using common, high-volume methods like injection molding or extrusion.

Instead, components are often machined from solid stock material. This process is slower and generates more waste, making individual PTFE parts relatively expensive.

Mechanical Properties (Creep)

A key consideration when designing with PTFE is its tendency to "creep" or "cold flow." This means the material can slowly deform over time when subjected to a sustained compressive load.

This behavior must be accounted for in the design of components like seals and gaskets to ensure long-term performance.

Making the Right Choice for Your Application

Selecting PTFE is a decision driven by the need for performance in extreme conditions. Use these points as a guide for your specific goal.

- If your primary focus is reducing friction and wear: PTFE is the definitive choice for self-lubricating bearings, seals, and non-stick surfaces.

- If your primary focus is chemical resistance: Its near-total inertness makes it ideal for containing or transporting aggressive chemicals where other materials would corrode.

- If your primary focus is biocompatibility: Its proven track record in medical implants makes it a trusted material for cardiovascular grafts and surgical patches.

- If your primary focus is cost-effective mass production: You must carefully weigh the high performance against the specialized and costly machining required to form PTFE parts.

By understanding its unique strengths and practical limitations, you can leverage PTFE to solve engineering challenges in the most demanding environments.

Summary Table:

| Characteristic | Key Benefit | Primary Application |

|---|---|---|

| Chemical Inertness | Resists nearly all chemicals | Corrosive chemical handling (seals, liners) |

| Thermal Stability | Performs from -70°C to 260°C | High-temperature environments |

| Low Friction | Self-lubricating, non-stick | Bearings, seals, non-stick coatings |

| Biocompatibility | Safe for use in the human body | Medical implants, surgical patches |

| Electrical Insulation | Excellent dielectric properties | High-performance wiring, cables |

Leverage PTFE's Extreme Performance for Your Application

Does your project in the semiconductor, medical, laboratory, or industrial sector demand the unique properties of PTFE? KINTEK specializes in the precision manufacturing of high-performance PTFE components—from custom seals, liners, and labware to complex prototypes and high-volume production runs.

We understand the critical balance between PTFE's superior characteristics and its design considerations, like creep resistance. Our expertise ensures your components are fabricated to the highest standards, delivering reliability in the most demanding environments.

Contact us today to discuss your specific requirements: Get in Touch

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What is Expanded PTFE and how does it differ from regular PTFE? Choosing the Right Material for Your Application

- Why is Teflon considered an exceptional material choice? Unmatched Chemical & Thermal Resistance

- What are mechanical engineering applications of Teflon? Solve Friction, Heat, and Chemical Challenges

- How does Teflon coating benefit cookware? Achieve Effortless Cooking and Easy Cleanup

- What are the three main steps in the manufacturing process of PTFE? From Monomer to High-Performance Polymer

- How does Teflon's friction coefficient benefit mechanical applications? Reduce Wear and Energy Consumption

- What is the chemical name for Teflon, and what is its abbreviation? Unveiling PTFE’s Unique Properties

- Why is PTFE important in the chemical and steel industries? Ensure Safety and Reliability in Harsh Environments