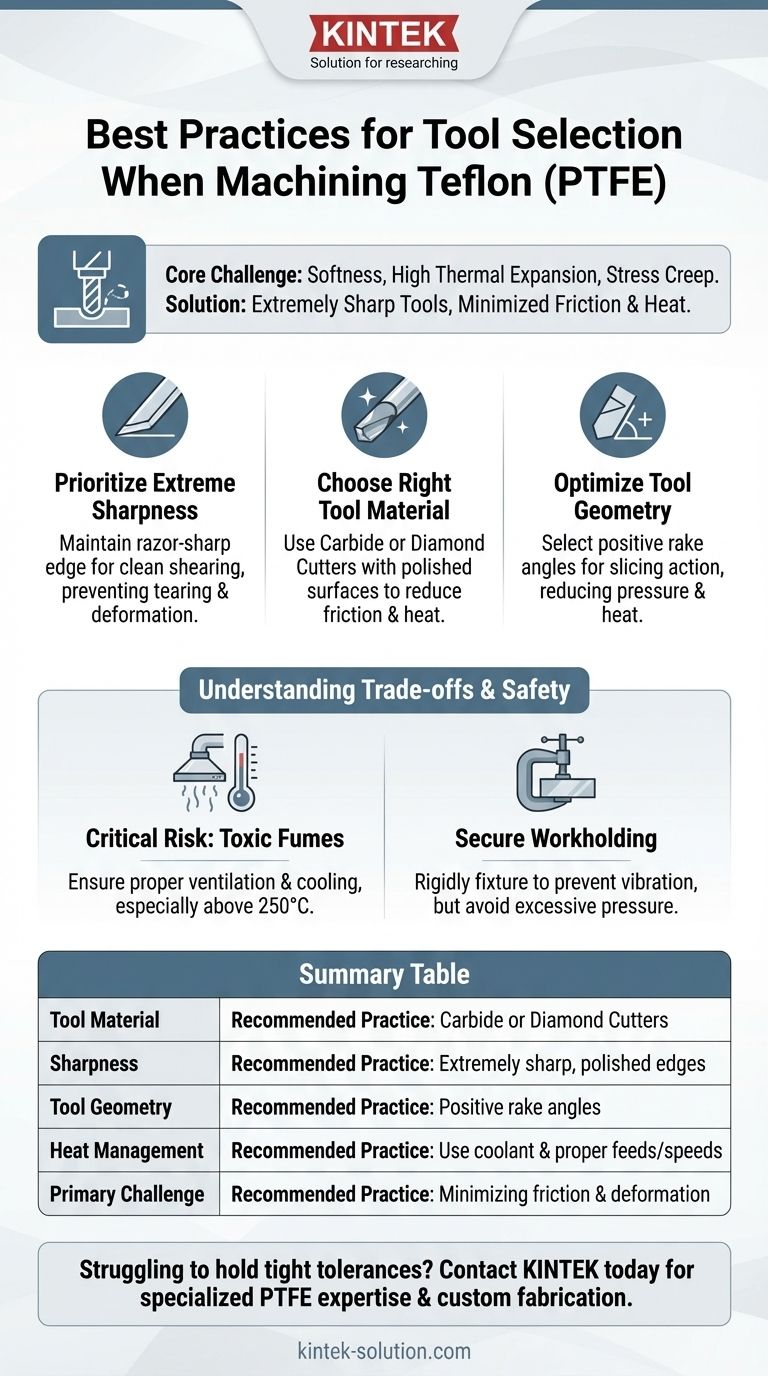

For machining Teflon (PTFE), the most effective practice is to use extremely sharp tools, typically made from carbide, that feature polished surfaces and positive rake angles. This combination is essential to slice the material cleanly rather than pushing it, which minimizes friction, heat generation, and deformation.

The core challenge in machining Teflon isn't hardness, but its unique combination of softness, high thermal expansion, and stress creep. Your tool selection strategy must prioritize minimizing cutting forces and heat to prevent the material from deforming and losing dimensional accuracy.

Why Teflon Machining Demands a Specialized Approach

Teflon’s properties make it deceptively simple to cut, yet difficult to machine accurately. Understanding these properties is the key to selecting the right tools and preventing common failures like poor surface finish and an inability to hold tolerances.

The Challenge of Softness and Low Strength

Teflon is exceptionally soft, which means tools can easily push and deform the material instead of cutting it. This leads to dimensional inaccuracies and "chatter," which ruins the surface finish.

To counteract this, your tools must be extremely sharp with a narrow cutting edge. A sharp tool requires less force, slicing through the material cleanly without causing it to compress or deflect.

The Problem of Thermal Expansion

Teflon has a very high coefficient of thermal expansion. Even a small amount of heat generated from friction during machining will cause the part to expand significantly.

When the part cools, it will contract, resulting in a final dimension that is smaller than intended. This makes holding tight tolerances incredibly difficult. The solution is to select tools that minimize friction and heat buildup.

The Difficulty of Holding Tight Tolerances

Beyond thermal expansion, Teflon is prone to stress creep. This means the material can slowly deform over time when under pressure, such as the force exerted by clamping or the cutting tool itself.

This property, combined with its softness, requires a machining strategy that is gentle and precise, starting with a tool geometry designed for low cutting forces.

Core Principles for Tool Selection

Based on Teflon's material properties, your tool selection should be guided by three main principles: sharpness, friction reduction, and proper geometry.

Prioritize Extreme Sharpness

This is the most critical factor. A dull or even moderately sharp tool will tear and deform Teflon. You must maintain a razor-sharp edge on all cutting tools to ensure a clean shearing action.

Regularly inspect and sharpen or replace tools to prevent degradation in cut quality.

Choose the Right Tool Material

Carbide is the most commonly recommended material for machining Teflon. It holds a sharp edge far longer than high-speed steel (HSS), leading to more consistent results over longer production runs.

For the best performance, use carbide tools with highly polished surfaces and flutes. A polished, mirror-like finish dramatically reduces friction, which in turn minimizes heat generation and prevents material from sticking to the tool. For specialized, high-volume applications, diamond cutters offer superior performance and tool life.

Optimize Tool Geometry

The shape of the cutting edge is crucial. Always select tools with positive rake angles. A positive rake angle creates a slicing action that lifts the chip away from the workpiece, reducing cutting pressure and heat.

For specific operations like drilling, consider specialized tools. Parabolic flute drills, for example, are excellent for evacuating the soft, stringy chips that Teflon produces, preventing them from binding in the hole.

Understanding the Trade-offs and Safety Concerns

Selecting the right tool is only part of the solution. You must also account for the operational environment and potential hazards.

The Critical Risk of Toxic Fumes

Teflon can begin to decompose at temperatures above 250°C (482°F), releasing toxic gases. Aggressive machining with the wrong tools can easily generate this level of heat.

Always ensure proper ventilation and use an effective cooling system. A non-aromatic, water-soluble coolant is highly recommended to manage temperature, improve surface finish, and extend tool life.

The Need for Secure Workholding

Because Teflon is so soft, it can easily vibrate or deflect during machining if not clamped securely. This vibration is a primary cause of poor surface finish.

Ensure your workpiece is rigidly fixtured, but be careful not to apply excessive clamping pressure that could deform the part or introduce internal stresses.

Making the Right Choice for Your Goal

Your optimal tool selection depends on your primary objective for the machining process.

- If your primary focus is achieving the tightest possible tolerances: Prioritize extremely sharp, polished tools and an effective cooling system to aggressively manage heat and thermal expansion.

- If your primary focus is maximizing production speed and tool life: Invest in polished carbide tooling, or even diamond cutters for high-volume jobs, to minimize wear and friction.

- If your primary focus is ensuring operator safety: Your top priority must be heat management through sharp tools, appropriate feeds and speeds, and a reliable cooling system to prevent the generation of toxic fumes.

By selecting tools that respect Teflon's unique material properties, you can move from fighting the material to achieving precise and repeatable results.

Summary Table:

| Key Consideration | Recommended Practice |

|---|---|

| Tool Material | Carbide or Diamond Cutters |

| Sharpness | Extremely sharp, polished edges |

| Tool Geometry | Positive rake angles |

| Heat Management | Use coolant and proper feeds/speeds |

| Primary Challenge | Minimizing friction and deformation |

Struggling to hold tight tolerances when machining Teflon/PTFE?

At KINTEK, we understand the unique challenges of machining PTFE components. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your parts are manufactured with the precision and care PTFE demands. We prioritize techniques that minimize heat and deformation to guarantee dimensional accuracy for the semiconductor, medical, laboratory, and industrial industries.

Let us put our specialized knowledge to work for you. Contact KINTEK today to discuss your PTFE component needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications