To ensure optimal performance and longevity, the best practices for installing PTFE sheets revolve around meticulous surface preparation and the use of appropriate bonding techniques. Maintenance focuses on regular, gentle cleaning and proactive inspections to preserve the material's unique low-friction surface and prevent mechanical damage.

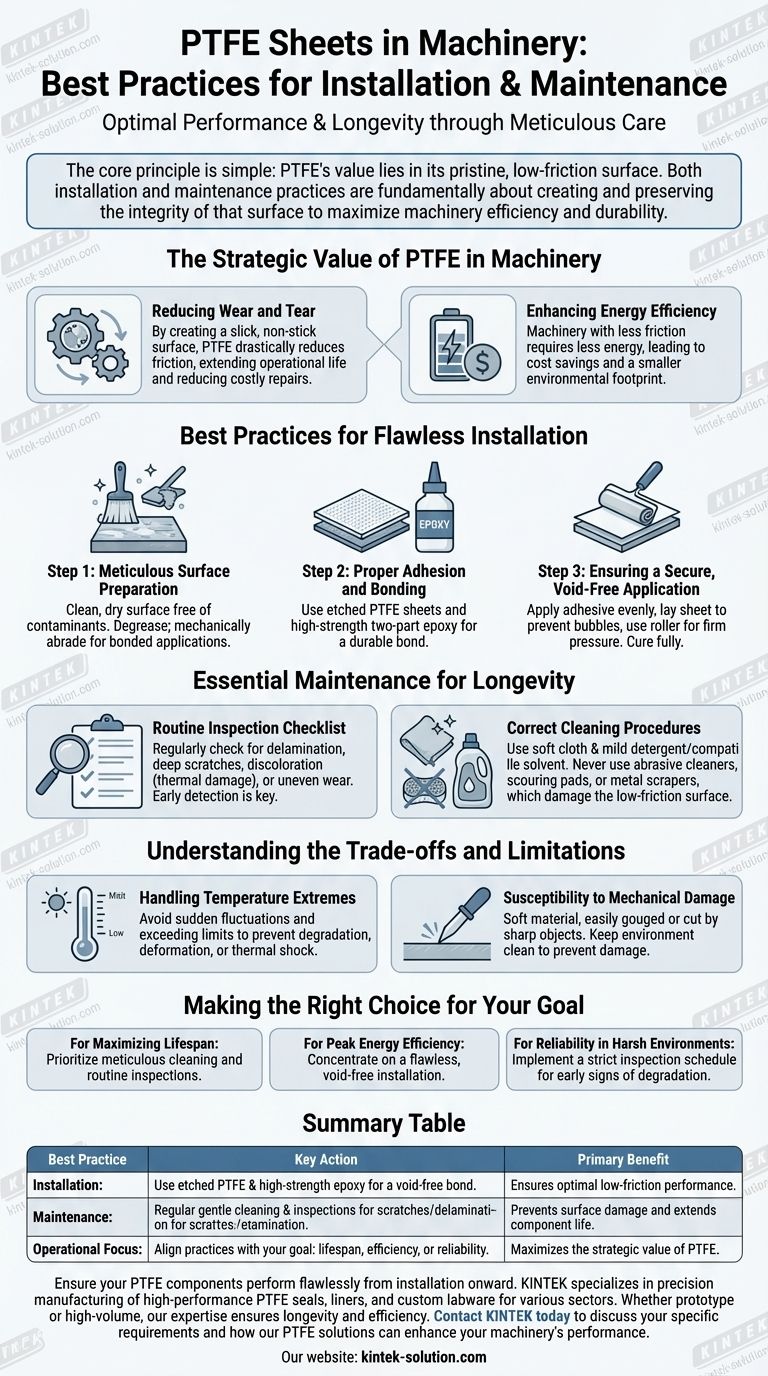

The core principle is simple: PTFE's value lies in its pristine, low-friction surface. Both installation and maintenance practices are fundamentally about creating and preserving the integrity of that surface to maximize machinery efficiency and durability.

The Strategic Value of PTFE in Machinery

Polytetrafluoroethylene (PTFE) is more than just a protective layer; it's a performance-enhancing component. Its primary value comes from an extremely low coefficient of friction.

Reducing Wear and Tear

By creating a slick, non-stick surface, PTFE sheets drastically reduce the friction between moving parts. This directly translates to less wear, extending the operational life of critical machine components and reducing the frequency of costly repairs.

Enhancing Energy Efficiency

Machinery operating with less friction requires less energy to perform the same task. This reduction in resistance means lower energy consumption, leading to significant cost savings and a smaller environmental footprint over the machine's lifecycle.

Best Practices for Flawless Installation

A successful installation is the foundation for PTFE's long-term performance. Any flaw in this stage will compromise its benefits.

Step 1: Meticulous Surface Preparation

The substrate must be perfectly clean, dry, and free of any contaminants like oil, grease, or dust. Using a suitable solvent for degreasing is a critical first step. For bonded applications, mechanically abrading or sandblasting the surface can create a better profile for the adhesive to grip.

Step 2: Proper Adhesion and Bonding

Standard PTFE is notoriously difficult to bond. For these applications, it is essential to use etched PTFE sheets, which have been chemically treated on one side to accept adhesives. A high-strength, two-part epoxy is often the recommended adhesive for creating a permanent, durable bond.

Step 3: Ensuring a Secure, Void-Free Application

Apply the adhesive evenly to the prepared substrate. Carefully lay the PTFE sheet, starting from one edge and working your way across to prevent trapping air bubbles. Use a roller or squeegee to apply firm, even pressure across the entire surface, ensuring a complete bond. Allow the adhesive to cure fully according to the manufacturer's instructions before putting the machinery back into service.

Essential Maintenance for Longevity

Proper maintenance is not about intensive work; it's about consistent, gentle care to protect the PTFE surface.

Routine Inspection Checklist

Regularly inspect the PTFE sheet for any signs of wear or damage. Look specifically for delamination (peeling away from the substrate), deep scratches, discoloration (which can indicate thermal damage), or uneven wear patterns. Early detection is key to preventing catastrophic failure.

Correct Cleaning Procedures

Clean the PTFE surface using a soft cloth and a mild detergent or solvent that is chemically compatible with your operational environment. Never use abrasive cleaners, scouring pads, or metal scrapers, as these will permanently damage the low-friction surface, negating the material's primary benefit.

Understanding the Trade-offs and Limitations

While highly effective, PTFE is not without its operational boundaries. Understanding these is crucial for proper application and maintenance.

Handling Temperature Extremes

PTFE has a wide operating temperature range, but it is not infinite. Exposing it to temperatures beyond its specified limits can cause it to degrade, deform, or lose its structural integrity. Avoid sudden, extreme temperature fluctuations, as this can cause thermal shock and stress the bond with the substrate.

Susceptibility to Mechanical Damage

PTFE is a relatively soft material. It is highly resistant to wear from smooth, sliding contact but can be easily gouged or cut by sharp objects or abrasive particles. Keeping the operational environment clean is a critical and often overlooked aspect of PTFE maintenance.

Making the Right Choice for Your Goal

Your maintenance and installation focus should align with your primary operational objective.

- If your primary focus is maximizing machinery lifespan: Prioritize meticulous cleaning and routine inspections to prevent abrasive contaminants from damaging the PTFE surface.

- If your primary focus is peak energy efficiency: Concentrate on a flawless installation, ensuring a perfect, void-free bond that guarantees the lowest possible coefficient of friction.

- If your primary focus is reliability in harsh environments: Implement a strict inspection schedule to look for early signs of thermal or chemical degradation before they compromise the component.

By treating PTFE installation and maintenance with this level of precision, you transform a simple sheet of material into a strategic asset for machine performance.

Summary Table:

| Best Practice | Key Action | Primary Benefit |

|---|---|---|

| Installation | Use etched PTFE & high-strength epoxy for a void-free bond. | Ensures optimal low-friction performance. |

| Maintenance | Regular gentle cleaning & inspections for scratches/delamination. | Prevents surface damage and extends component life. |

| Operational Focus | Align practices with your goal: lifespan, efficiency, or reliability. | Maximizes the strategic value of PTFE in your application. |

Ensure your PTFE components perform flawlessly from installation onward. KINTEK specializes in the precision manufacturing of high-performance PTFE seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our expertise ensures you get components designed for longevity and efficiency.

Contact KINTEK today to discuss your specific requirements and how our PTFE solutions can enhance your machinery's performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications