The definitive best practices for installing and maintaining PTFE expansion joints revolve around meticulous alignment, strict adherence to manufacturer specifications, and a proactive inspection schedule. These components are critical for absorbing movement and vibration in piping systems, and their reliability is directly tied to the precision of their installation and the diligence of their upkeep.

The central principle is this: an expansion joint is designed to manage the dynamic movements of a properly installed system, not to correct for static installation errors. Its longevity depends entirely on creating a low-stress environment where it can function as intended.

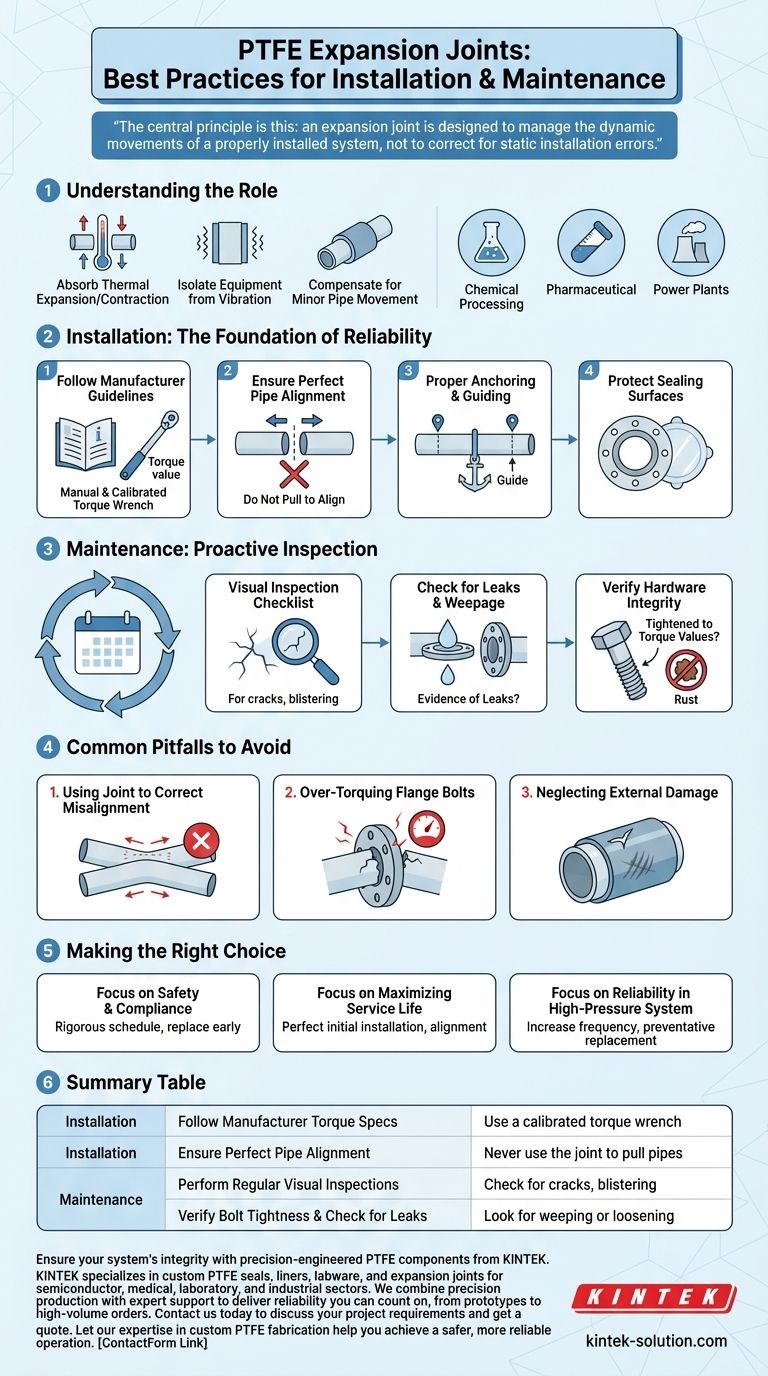

Understanding the Role of PTFE Expansion Joints

Before diving into procedures, it's crucial to understand why these components are so vital. They are not merely connectors; they are engineered solutions to complex physical forces within a pipeline.

What They Do

PTFE (Polytetrafluoroethylene) expansion joints are flexible connectors that serve a critical function. They absorb thermal expansion and contraction, isolate equipment from vibration, and compensate for minor pipe movement to maintain the overall integrity of the pipeline.

Where They Are Used

Their exceptional chemical resistance and durability make them essential in demanding environments. You will find them in chemical processing plants handling corrosive materials, pharmaceutical facilities requiring hygiene and purity, and power plants withstanding high-pressure steam and temperature fluctuations.

Installation: The Foundation of Reliability

The installation phase is the single most important factor in determining the service life and safety of a PTFE expansion joint. Errors made here will inevitably lead to premature failure.

The Golden Rule: Follow Manufacturer Guidelines

Every expansion joint is engineered for specific conditions. The manufacturer's installation manual is the authoritative document and must be followed precisely, especially regarding torque values for bolts and allowable movement limits.

The Critical Importance of Pipe Alignment

The connecting pipes must be perfectly aligned before installing the joint. The expansion joint must never be used to pull pipes into alignment. Forcing a fit introduces lateral or angular stress that the joint was not designed to handle, causing rapid wear and failure.

Ensure Proper Anchoring and Guiding

The piping system itself must be properly anchored and guided. Anchors direct thermal movement into the expansion joint, while guides prevent the pipe from buckling or bowing under pressure. Without these, forces can be misdirected, overwhelming the joint.

Protect the Sealing Surfaces

The PTFE sealing surfaces are critical for preventing leaks. They must be kept clean and protected from scratches, dents, or any other damage during handling and installation. Never use sharp tools to scrape the flange faces.

Maintenance: A Proactive Inspection Program

Once installed, reliability depends on regular and thorough inspections. This is not a "fit and forget" component, especially in high-pressure or chemically aggressive environments.

The Visual Inspection Checklist

At regular intervals, visually inspect the entire assembly. Look for any signs of cracking, blistering, discoloration, or delamination on both the inner PTFE liner and the outer reinforcement.

Check for Leaks and Weepage

Examine the flange connections for any evidence of leaks or chemical weeping. Even minor leakage is a clear indicator that the seal is compromised and requires immediate attention.

Verify Hardware Integrity

Vibration and thermal cycling can cause bolts to loosen over time. Periodically check that all fasteners are tightened to the manufacturer's specified torque values. Inspect for any signs of corrosion on bolts, nuts, and flanges.

Common Pitfalls to Avoid

Mistakes with expansion joints are common and costly. Understanding these pitfalls is key to preventing them.

Mistake #1: Using the Joint to Correct Misalignment

This is the most frequent cause of failure. An expansion joint used as a "fudge factor" to connect misaligned pipes is under constant, unintended stress and will fail.

Mistake #2: Over-Torquing Flange Bolts

While loose bolts are a problem, over-tightening is just as damaging. Excessive torque can crack the flange, crush the PTFE sealing face, and create a leak path. Always use a calibrated torque wrench.

Mistake #3: Neglecting External Damage

Do not focus solely on the internal liner. The outer cover protects the reinforcement layers from the environment. Any cuts, abrasions, or UV damage to the exterior can compromise the joint's structural integrity.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your system's operational priorities.

- If your primary focus is safety and compliance: Implement a rigorous, documented inspection schedule and replace joints at the very first sign of wear or degradation.

- If your primary focus is maximizing service life: Invest heavily in a perfect initial installation, ensuring precise pipe alignment and proper anchoring to prevent the chronic stresses that cause most failures.

- If your primary focus is reliability in a high-pressure system: Increase the frequency of inspections and consider a time-based, preventative replacement schedule rather than waiting for a failure to occur.

Treating PTFE expansion joints as engineered components, not simple fittings, is the key to unlocking their full potential for safety and reliability.

Summary Table:

| Best Practice Category | Key Action | Critical Detail |

|---|---|---|

| Installation | Follow Manufacturer Torque Specs | Use a calibrated torque wrench to avoid damage. |

| Installation | Ensure Perfect Pipe Alignment | Never use the joint to pull pipes into position. |

| Maintenance | Perform Regular Visual Inspections | Check for cracks, blistering, or discoloration. |

| Maintenance | Verify Bolt Tightness & Check for Leaks | Look for weeping or signs of fastener loosening. |

Ensure your system's integrity with precision-engineered PTFE components from KINTEK.

Proper installation and maintenance are critical, but they start with a high-quality expansion joint designed for your specific application. KINTEK specializes in manufacturing custom PTFE seals, liners, labware, and expansion joints for the semiconductor, medical, laboratory, and industrial sectors. We combine precision production with expert support to deliver reliability you can count on, from prototypes to high-volume orders.

Contact us today to discuss your project requirements and get a quote. Let our expertise in custom PTFE fabrication help you achieve a safer, more reliable operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability