In demanding industrial applications, the benefits of a PTFE reducing flange extend far beyond simply connecting two different pipe sizes. They provide unparalleled chemical resistance, function across a wide temperature range, and possess a unique non-stick surface. These core attributes translate directly into enhanced process efficiency, superior safety, and significant long-term cost-effectiveness.

A PTFE reducing flange is not just a connector; it is a problem-solver for the most challenging points in a piping system. It ensures that the transition between pipe sizes does not become a weak link for corrosion, contamination, or blockages.

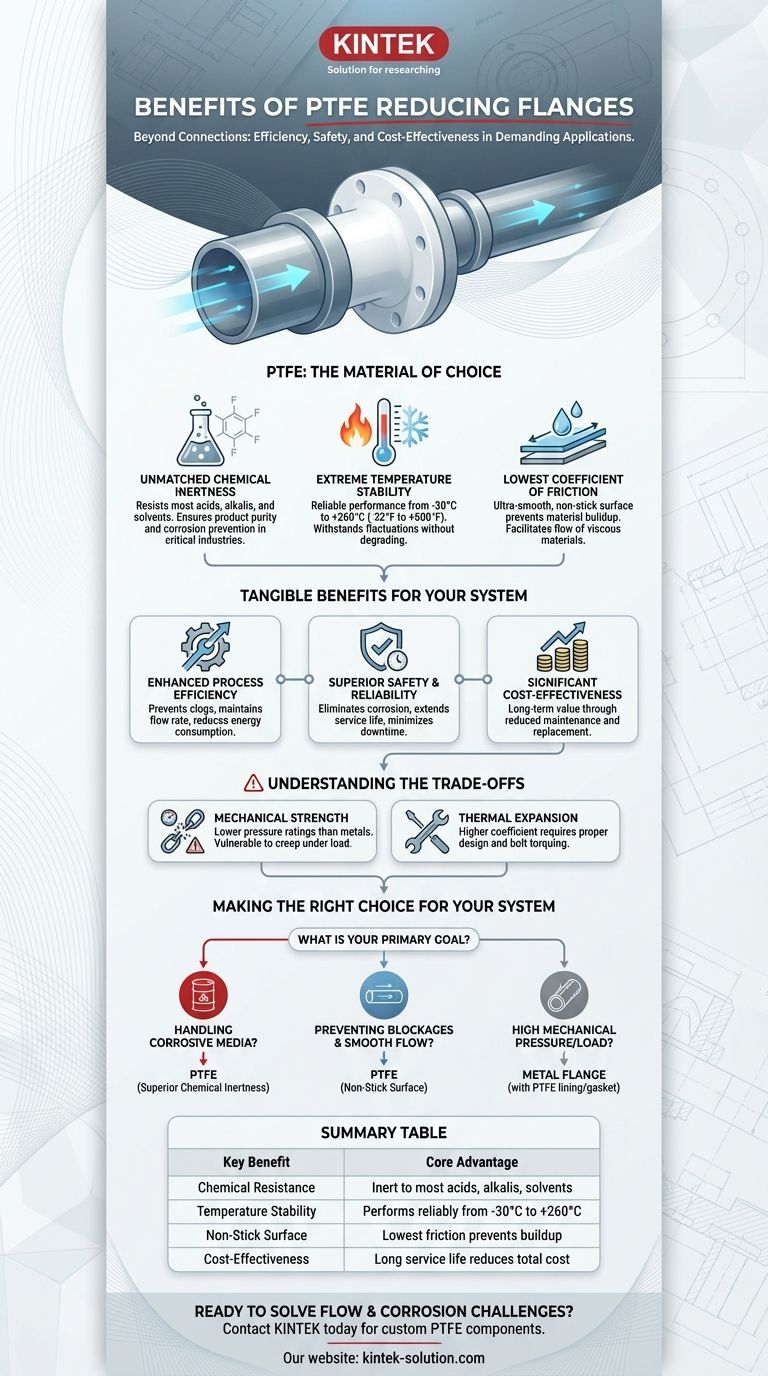

Why PTFE is the Material of Choice for Critical Applications

The value of a PTFE reducing flange is rooted in the fundamental properties of its material, Polytetrafluoroethylene (PTFE). This material provides a unique combination of characteristics that are difficult to find in any other single polymer or metal.

Unmatched Chemical Inertness

PTFE is renowned for its near-universal resistance to chemical attack. It remains completely unaffected by most acids, alkalis, solvents, and other aggressive substances.

This property makes it an essential material in chemical processing, pharmaceutical manufacturing, and semiconductor industries where product purity and the prevention of corrosion are paramount.

Extreme Temperature Stability

Thanks to the powerful carbon-fluorine bonds in its molecular structure, PTFE maintains its integrity across an exceptionally wide operating temperature range, typically from -30°C to +260°C (-22°F to +500°F).

This allows it to perform reliably in systems that experience significant temperature fluctuations, from cryogenic applications to high-heat processes, without becoming brittle or degrading.

The Lowest Coefficient of Friction

PTFE has the lowest coefficient of friction of any known solid material, giving it an extremely smooth, non-stick surface.

This is often compared to the difficulty of getting two wet ice cubes to stick together. In a piping system, this means materials—especially viscous or sticky ones—flow past it with minimal resistance.

Translating Material Properties into Tangible Benefits

Understanding the core properties of PTFE allows us to see how they deliver concrete advantages in an operational environment.

Enhanced Process Efficiency

The non-stick surface of a PTFE flange is critical for maintaining consistent flow. It prevents material from adhering to the flange's internal surfaces, which minimizes the risk of clogs and blockages.

By reducing friction and buildup, the system maintains its designed flow rate, which enhances overall productivity and reduces the energy required for pumping.

Superior Safety and Reliability

In systems handling hazardous chemicals, a leak is not an option. PTFE's chemical inertness prevents the flange itself from becoming a point of failure due to corrosion.

Furthermore, its durability and resistance to aging mean it has a very long service life. This reduces the need for frequent replacement and minimizes system downtime, creating a more reliable and safer operation.

Significant Cost-Effectiveness

While the initial investment may be higher than for some metal flanges, the total cost of ownership is often much lower.

The long service life, minimal maintenance requirements, and prevention of costly downtime for repairs or cleanouts make PTFE a highly cost-effective solution for demanding applications.

Understanding the Trade-offs

No material is perfect for every situation. To make an informed decision, it's critical to understand the limitations of PTFE.

Mechanical Strength and Pressure

PTFE is a polymer, not a metal. It has lower tensile strength and is more susceptible to "creep" (a slow deformation under sustained load) than steel or other metal alloys.

This means PTFE flanges have lower pressure and temperature ratings compared to their metal counterparts. They are not suitable for high-pressure structural applications without reinforcement.

Thermal Expansion

PTFE has a significantly higher coefficient of thermal expansion than metals. In systems with wide and rapid temperature swings, this must be accounted for during design and installation to maintain a proper seal.

Proper bolt torquing procedures are essential to accommodate this expansion and contraction and prevent leaks from developing over time.

Making the Right Choice for Your System

Selecting a PTFE reducing flange depends on balancing its powerful advantages against its specific limitations and your primary operational goal.

- If your primary focus is handling highly corrosive media: The chemical inertness of PTFE makes it the superior choice, preventing material degradation and ensuring system purity.

- If your primary focus is preventing blockages or ensuring smooth flow: PTFE's non-stick surface is invaluable for processes involving viscous, sticky, or high-purity materials.

- If your primary focus is high mechanical pressure or structural load: A metal flange, perhaps lined with PTFE or used with a PTFE gasket, is a more appropriate choice to handle the structural stress.

By understanding its unique profile, you can leverage the PTFE reducing flange as a strategic component for creating a robust, efficient, and safe piping system.

Summary Table:

| Key Benefit | Core Advantage |

|---|---|

| Chemical Resistance | Inert to most acids, alkalis, and solvents, ensuring purity and preventing corrosion. |

| Temperature Stability | Performs reliably from -30°C to +260°C (-22°F to +500°F). |

| Non-Stick Surface | Lowest coefficient of friction prevents material buildup and clogging. |

| Cost-Effectiveness | Long service life and minimal maintenance reduce total cost of ownership. |

Ready to solve your toughest flow and corrosion challenges?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom reducing flanges, seals, liners, and labware. Our expertise ensures your critical applications in the semiconductor, medical, laboratory, and industrial sectors benefit from superior material properties and reliable performance.

We partner with you from prototype to high-volume production, delivering the exact specifications you need for safety, efficiency, and long-term value.

Contact KINTEK today to discuss your specific requirements and get a quote for your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications