In short, fillers are added to Polytetrafluoroethylene (PTFE) to enhance its mechanical and physical properties. While pure PTFE offers remarkable characteristics like low friction and chemical resistance, it is mechanically soft. Fillers are used to significantly improve its wear resistance, reduce deformation under load (creep), increase strength, and modify thermal or electrical properties for specific engineering applications.

While pure PTFE is an exceptional polymer, its inherent softness limits its use in demanding structural or dynamic roles. Fillers are the primary method for transforming PTFE into a robust engineering material, customizing its properties to overcome specific challenges like high loads, abrasion, or thermal management.

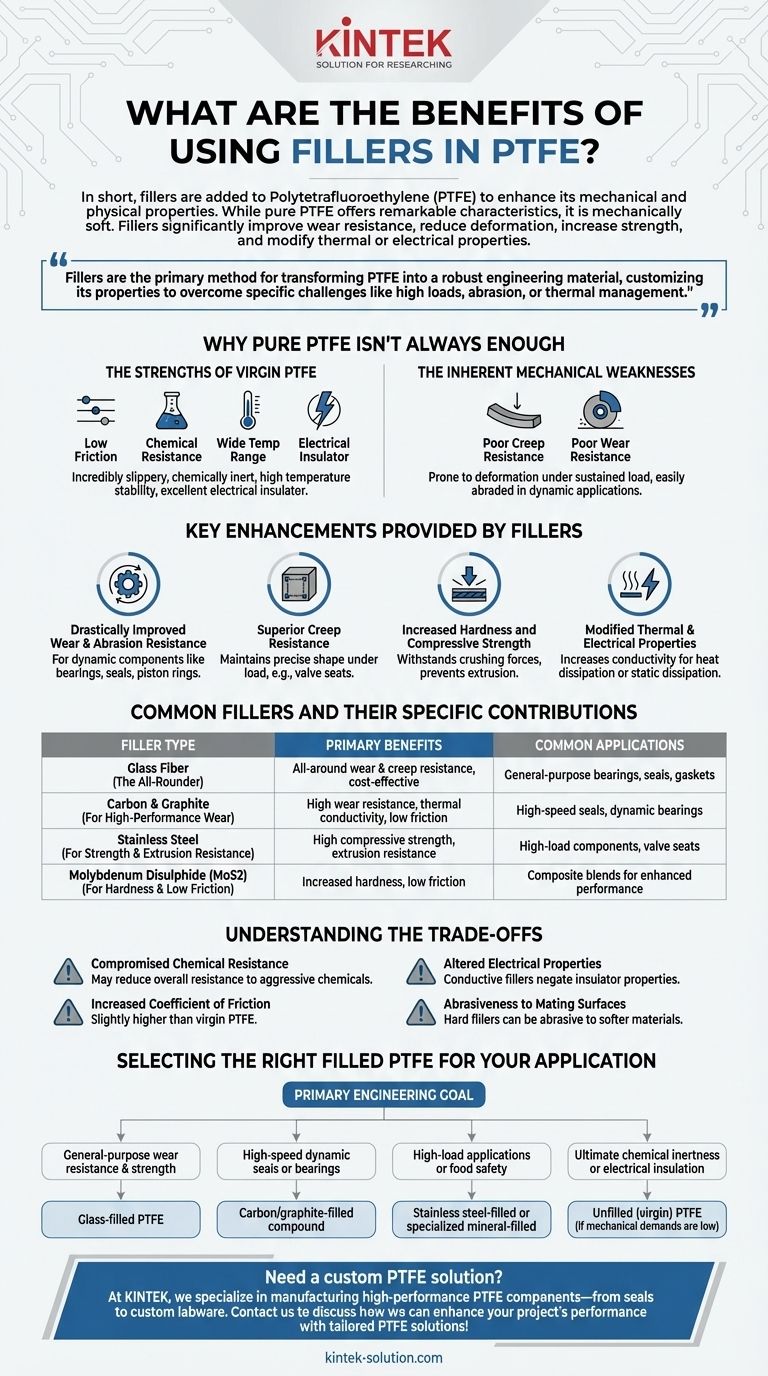

Why Pure PTFE Isn't Always Enough

The Strengths of Virgin PTFE

Virgin, or unfilled, PTFE is a unique material valued for several core properties. It has one of the lowest coefficients of friction of any solid, making it incredibly slippery.

It also offers outstanding chemical resistance across a wide range of substances and maintains its properties over a broad operating temperature range (up to +260°C). Furthermore, it is an excellent electrical insulator.

The Inherent Mechanical Weaknesses

The primary drawback of virgin PTFE is its poor mechanical strength. It is a relatively soft material that is prone to two key failures.

First, it has low resistance to creep, which is the tendency to slowly deform or flow when subjected to a sustained load. Second, it has poor wear resistance, meaning it can be easily abraded in dynamic applications.

Key Enhancements Provided by Fillers

Drastically Improved Wear & Abrasion Resistance

Adding a filler material creates a composite that is significantly harder and more durable than pure PTFE. This is the most common reason for using a filler.

This enhancement allows filled PTFE to be used in dynamic components like bearings, seals, and piston rings where it will be subjected to constant friction.

Superior Creep Resistance

Fillers act as a reinforcing skeleton within the soft PTFE matrix. This structure provides rigidity and support, drastically reducing the material's tendency to deform under sustained pressure.

This property is critical for components that must maintain their precise shape under load, such as valve seats and high-pressure gaskets.

Increased Hardness and Compressive Strength

Fillers like glass fiber and stainless steel significantly increase the material's hardness and its ability to withstand crushing forces. This prevents the material from being physically damaged or extruded from its housing under high loads.

Modified Thermal & Electrical Properties

While pure PTFE is an excellent thermal and electrical insulator, some applications require conductivity.

Fillers like carbon, graphite, and stainless steel can be added to increase thermal conductivity, helping to dissipate heat in high-speed applications. These same fillers can also make the material electrically conductive, which is useful for static dissipation.

Common Fillers and Their Specific Contributions

The choice of filler is determined entirely by the demands of the application. Each type offers a unique profile of benefits.

Glass Fiber (The All-Rounder)

This is the most widely used filler in PTFE. It provides an excellent all-around improvement in wear resistance, creep resistance, and compressive strength at a reasonable cost.

Carbon & Graphite (For High-Performance Wear)

Carbon provides excellent wear and creep resistance. When blended with graphite, it also improves thermal conductivity and maintains a low coefficient of friction, making it ideal for high-speed, high-pressure dynamic seals.

Stainless Steel (For Strength & Extrusion Resistance)

Adding stainless steel powder creates a very strong, hard-wearing material. It is particularly effective in high-load applications and provides excellent resistance to extrusion (being forced out of a gap).

Molybdenum Disulphide (MoS2) (For Hardness & Low Friction)

Often used in combination with other fillers, MoS2 increases the hardness and stiffness of the PTFE composite while also helping to reduce its coefficient of friction.

Understanding the Trade-offs

Adding fillers is not a universal improvement. You must consider the compromises to PTFE's inherent properties.

Compromised Chemical Resistance

Pure PTFE is nearly chemically inert. However, the filler material may not be, which can reduce the compound's overall resistance to certain aggressive chemicals.

Increased Coefficient of Friction

While still very low, the coefficient of friction for a filled PTFE is almost always slightly higher than that of virgin PTFE.

Altered Electrical Properties

Adding conductive fillers like carbon or stainless steel will negate PTFE's natural properties as an excellent electrical insulator.

Abrasiveness to Mating Surfaces

Hard fillers, particularly glass fiber, can be abrasive to softer counter-surfaces like aluminum or plastic. The hardness of the mating hardware must be a key design consideration.

Selecting the Right Filled PTFE for Your Application

The ideal material is a direct function of your primary engineering goal.

- If your primary focus is general-purpose wear resistance and strength: Glass-filled PTFE is the most common and cost-effective starting point.

- If your primary focus is high-speed dynamic seals or bearings: A carbon/graphite-filled compound offers excellent wear properties and thermal conductivity to dissipate heat.

- If your primary focus is high-load applications or food safety: Consider stainless steel-filled PTFE for its high compressive strength or a specialized mineral-filled grade for compliance.

- If your primary focus is ultimate chemical inertness or electrical insulation: Unfilled (virgin) PTFE remains the superior choice, provided the mechanical demands are low.

By understanding these enhancements and trade-offs, you can select a filled PTFE compound that is precisely engineered to meet your specific performance requirements.

Summary Table:

| Filler Type | Primary Benefits | Common Applications |

|---|---|---|

| Glass Fiber | All-around wear & creep resistance, cost-effective | General-purpose bearings, seals, gaskets |

| Carbon/Graphite | High wear resistance, thermal conductivity | High-speed seals, dynamic bearings |

| Stainless Steel | High compressive strength, extrusion resistance | High-load components, valve seats |

| Molybdenum Disulphide (MoS2) | Increased hardness, low friction | Composite blends for enhanced performance |

Need a custom PTFE solution for your specific application? At KINTEK, we specialize in manufacturing high-performance PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our precision production and custom fabrication expertise ensure your filled PTFE parts meet exact mechanical, thermal, and chemical demands. Contact us today to discuss how we can enhance your project’s performance with tailored PTFE solutions!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE's biocompatibility and its medical applications? A Guide to Safe, Non-Reactive Medical Devices

- In which industries is PTFE commonly used? Discover High-Performance Applications

- What makes PTFE a revolutionary material in modern engineering? Unlock Unmatched Chemical & Thermal Resistance

- How is Teflon made? The Science Behind Its Incredible Properties

- What are the key properties of PTFE relevant to troubleshooting and maintenance? Master PTFE's Strengths and Weaknesses

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How is Fine Powder PTFE different from Granular PTFE? Choose the Right Material for Your Process

- What were the unexpected properties of the newly discovered PTFE? Unveiling the Game-Changing Material