At its core, PTFE Industrial and Heavy Wall tubing is chosen for its exceptional durability and resilience in demanding operational environments. Its primary benefits are superior resistance to virtually all industrial chemicals and solvents, high-temperature stability up to 500°F (260°C), and a robust physical structure that resists mechanical stress and ensures a long service life.

The decision to use PTFE Industrial and Heavy Wall tubing is not just a material choice; it is a strategic investment in system reliability. Its unique properties are designed to prevent equipment failure, reduce maintenance, and ensure operational integrity in the harshest chemical and thermal conditions.

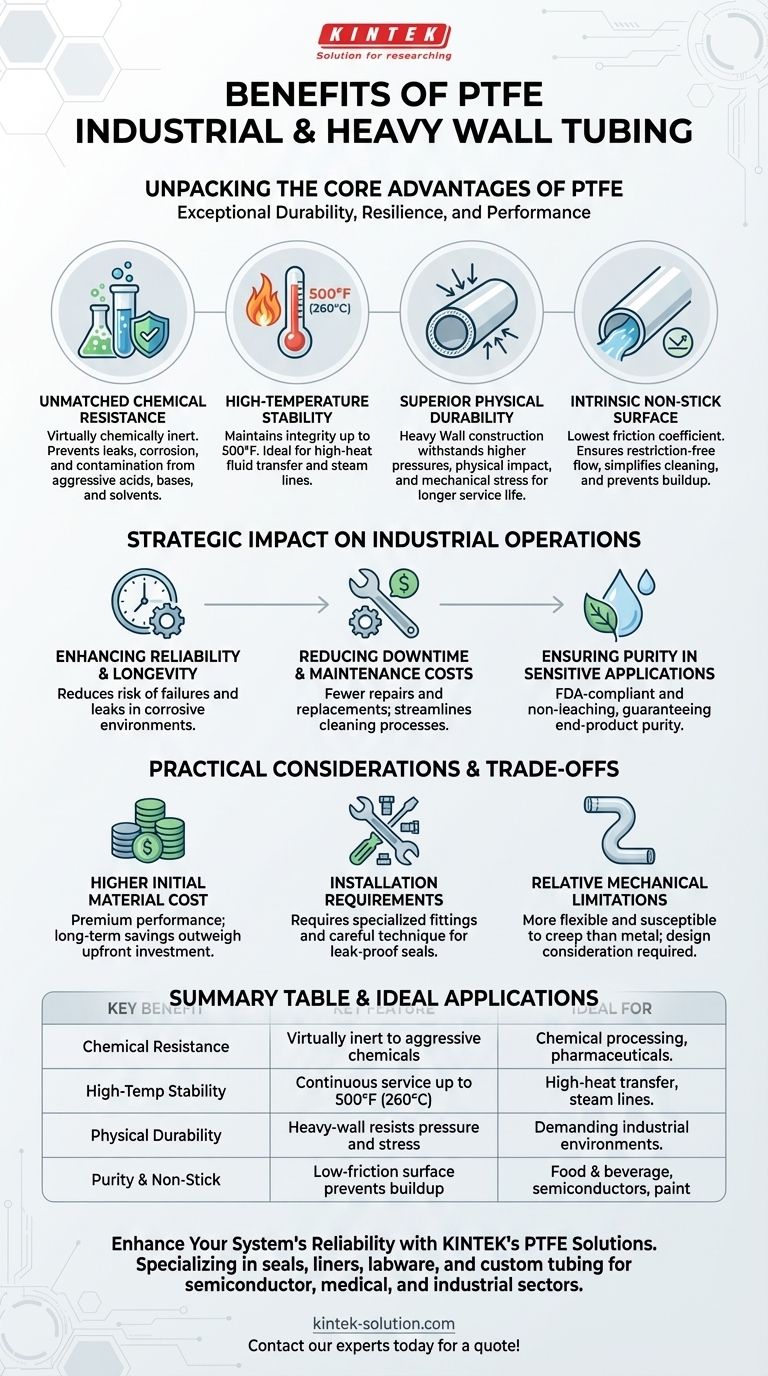

Unpacking the Core Advantages of PTFE

The value of PTFE tubing stems from a unique combination of chemical, thermal, and physical properties that outperform conventional plastics and even some metals in specific scenarios.

Unmatched Chemical and Solvent Resistance

PTFE is virtually chemically inert. This means it will not react with or degrade when exposed to the most aggressive acids, bases, and solvents used in industrial processes.

This inertness is critical for preventing leaks, corrosion, and contamination within a fluid handling system, protecting both the equipment and the purity of the product being transferred.

High-Temperature Stability

This tubing maintains its structural integrity and performance characteristics at continuous service temperatures up to 500°F (260°C).

Where other polymers would soften, melt, or leach chemicals, PTFE remains stable, making it a default choice for high-heat fluid transfer, steam lines, and other thermally demanding applications.

Superior Physical Durability

The "Heavy Wall" designation is key. This indicates a thicker, more robust construction designed to withstand higher pressures, physical impact, and mechanical stress compared to standard tubing.

This added durability translates directly to a longer service life and greater resistance to kinking or collapse, especially in dynamic industrial settings.

Intrinsic Non-Stick and Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid material, creating an exceptionally smooth, non-stick internal surface.

This property ensures restriction-free fluid flow and significantly simplifies cleaning. It prevents materials from building up on the tube walls, which is crucial for applications in food processing, pharmaceuticals, and paint delivery.

The Strategic Impact on Industrial Operations

Selecting PTFE Heavy Wall tubing goes beyond simple material specifications. It has a direct and positive impact on operational efficiency, safety, and profitability.

Enhancing System Reliability and Longevity

By resisting chemical attack and thermal degradation, PTFE tubing provides a reliable, long-lasting sealing and transport solution.

This durability drastically reduces the risk of premature leaks and catastrophic equipment failures, which are common points of failure for less robust materials in corrosive environments.

Reducing Downtime and Maintenance Costs

The inherent reliability of PTFE directly lowers operational costs. Fewer failures mean less unplanned downtime for repairs and a reduced need for frequent component replacement.

Its non-stick surface can also streamline Clean-in-Place (CIP) procedures, further minimizing the time and resources spent on maintenance.

Ensuring Purity in Sensitive Applications

In industries like pharmaceuticals, food and beverage, and semiconductors, preventing contamination is non-negotiable.

PTFE's chemical inertness and FDA-compliant status ensure that nothing leaches from the tubing into the fluid it carries. This guarantees the purity and integrity of the end product.

Understanding the Practical Considerations

While its benefits are significant, PTFE is not a universal solution. Acknowledging its trade-offs is crucial for making an informed decision.

Higher Initial Material Cost

PTFE is a premium performance polymer, and its upfront cost is higher than that of common materials like PVC, nylon, or polyethylene. This initial investment must be weighed against the long-term savings from reduced maintenance and increased reliability.

Installation and Fitting Requirements

To achieve a reliable, leak-proof seal, especially under high pressure or temperature, PTFE tubing often requires specialized fittings and careful installation techniques. Improper installation can compromise the integrity of the entire system.

Relative Mechanical Limitations

While the "heavy wall" design improves its rigidity, PTFE is inherently more flexible and susceptible to creep (deformation under sustained load) than metal tubing. In applications with extreme structural or pressure demands, this must be a design consideration.

Making the Right Choice for Your Application

Ultimately, the choice to use PTFE Industrial and Heavy Wall tubing should be driven by the specific demands of your project.

- If your primary focus is handling highly corrosive chemicals or solvents: PTFE is the safest and most reliable choice due to its near-total chemical inertness.

- If your primary focus is high-temperature fluid transfer: Its 500°F (260°C) service temperature makes it one of the few viable polymer options.

- If your primary focus is maximizing system uptime in a harsh environment: The combination of durability and chemical resistance makes it a strategic investment to minimize failure.

- If your primary focus is maintaining product purity: PTFE's non-stick, non-leaching properties and FDA compliance are its key differentiators.

Choosing this material is a deliberate decision to prioritize long-term performance and safety over short-term cost savings.

Summary Table:

| Key Benefit | Key Feature | Ideal For |

|---|---|---|

| Chemical Resistance | Virtually inert to aggressive acids, bases, solvents | Chemical processing, pharmaceuticals |

| High-Temp Stability | Continuous service up to 500°F (260°C) | High-heat fluid transfer, steam lines |

| Physical Durability | Heavy-wall construction resists pressure and stress | Demanding industrial environments |

| Purity & Non-Stick | Low-friction surface prevents contamination and buildup | Food & beverage, semiconductors, paint |

Ready to enhance your system's reliability with high-performance PTFE components?

At KINTEK, we specialize in the precision manufacturing of PTFE seals, liners, labware, and custom tubing for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a custom prototype or a high-volume order, our expertise ensures you get a solution built for durability and performance in your most demanding applications.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How can PTFE lip seals be enhanced for extreme temperature performance? Optimize with Fillers & Design

- How can Teflon PTFE sheets assist in crafting with glue or resin? Achieve a Clean, Reusable Workspace

- What types of fluids can PTFE control valves handle? Master Corrosive Chemicals with Confidence

- What are the advantages of using Teflon backup rings in chemical processing? Protect Seals from Harsh Chemicals & Extreme Temperatures

- How is PTFE used in the automotive industry? Enhancing Vehicle Reliability and Performance

- How are PTFE gaskets utilized in electrical components? Ensure Superior Insulation & Sealing

- What temperature range can PTFE seals typically operate in? From Cryogenic -200°C to High-Temp 260°C

- Why are PTFE gaskets suitable for pharmaceutical and food equipment? Ensure Purity and FDA Compliance