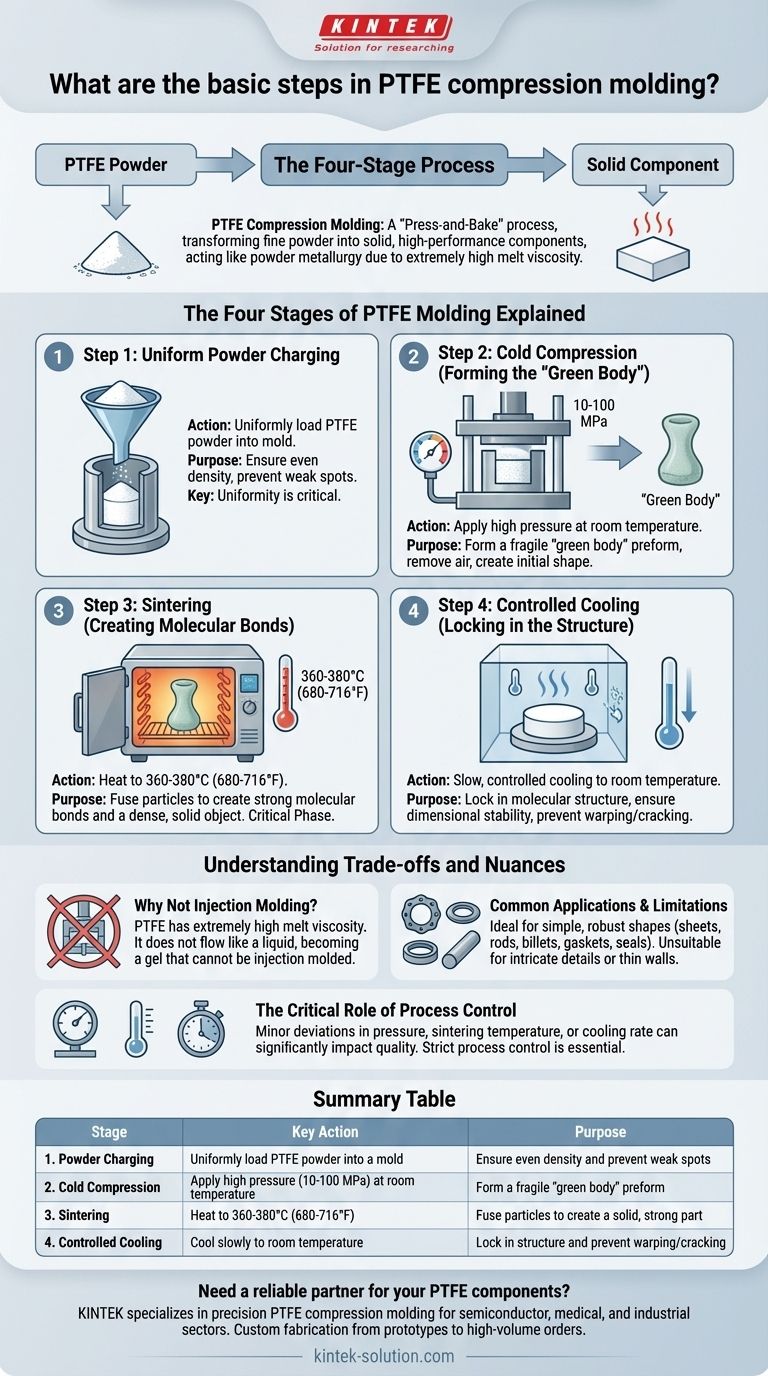

At its core, PTFE compression molding is a four-stage process that transforms a fine powder into a solid, high-performance component. It involves uniformly filling a mold with PTFE resin, compressing it under high pressure at room temperature, heating it in a process called sintering to fuse the particles, and finally, cooling it under controlled conditions to achieve its final form.

Unlike common plastics that are melted and injected, PTFE has an extremely high melt viscosity, making it impossible to process conventionally. Therefore, compression molding acts more like powder metallurgy—a "press-and-bake" method that fuses particles together without ever reaching a true liquid state.

The Four Stages of PTFE Molding Explained

Each step in the compression molding process is critical for developing the unique properties of the final PTFE part, from its chemical resistance to its mechanical strength.

Step 1: Uniform Powder Charging

The process begins by carefully loading a specific amount of PTFE powder into a mold cavity.

The key to this stage is uniformity. Any uneven distribution of the powder can lead to variations in density, creating weak spots and compromising the structural integrity of the finished component.

Step 2: Cold Compression (Forming the "Green Body")

Next, the powder is compressed at room temperature using pressures ranging from 10 to 100 MPa.

This high pressure forces the individual powder particles into close contact, removing air and creating a fragile, preliminary shape. This pre-sintered form is often called a "green body" or a preform. It has the correct shape but lacks any significant mechanical strength.

Step 3: Sintering (Creating Molecular Bonds)

The green body is carefully removed from the mold and placed into an oven for sintering, the most critical phase of the process.

The component is heated to a precise temperature between 360-380°C (680-716°F). At this temperature, the PTFE particles fuse together, creating strong molecular bonds and transforming the fragile preform into a dense, solid object. This is where the material's final mechanical properties are established.

Step 4: Controlled Cooling (Locking in the Structure)

After sintering, the component must be cooled back to room temperature in a highly controlled manner.

Slow cooling is essential. Rapid cooling can introduce internal stresses, leading to warping or even cracking. This final stage solidifies the part's molecular structure and ensures its dimensional stability and performance.

Understanding the Trade-offs and Nuances

While straightforward, the success of PTFE compression molding hinges on understanding its unique requirements and limitations.

Why Not Use Traditional Injection Molding?

The primary reason for this specialized process is PTFE's extremely high melt viscosity. Even when heated above its melting point, it does not flow like a liquid. Instead, it becomes a viscous, gel-like substance that cannot be forced into a mold with the speed and precision of injection molding.

Common Applications and Limitations

Compression molding is ideal for producing simple, robust shapes with thick walls.

This method excels at creating stock materials like sheets, rods, and billets, which are often machined into more complex parts. It is also perfect for manufacturing components like gaskets, seals, and bearings. However, it is generally unsuitable for creating parts with intricate details or thin walls.

The Critical Role of Process Control

The quality of a molded PTFE part is highly sensitive to process variables. Minor deviations in pressure, sintering temperature, or cooling rate can significantly impact the final part's density, porosity, and mechanical strength. This makes strict process control absolutely essential for producing reliable components.

Making the Right Choice for Your Goal

Understanding this process allows you to specify parts and materials more effectively.

- If your primary focus is component reliability: Insist on controlled sintering and cooling cycles, as these steps are most critical for ensuring consistent material properties and preventing premature failure.

- If your primary focus is producing simple stock shapes: Recognize that compression molding is the most direct and cost-effective method for creating high-quality PTFE billets, rods, and sheets for subsequent machining.

- If your primary focus is designing complex parts: Understand that your part will likely be machined from a compression-molded stock shape rather than molded directly, which will influence design considerations like feature size and tolerances.

Mastering these four fundamental steps is the key to successfully specifying, manufacturing, or troubleshooting any compression-molded PTFE component.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1. Powder Charging | Uniformly load PTFE powder into a mold | Ensure even density and prevent weak spots |

| 2. Cold Compression | Apply high pressure (10-100 MPa) at room temperature | Form a fragile "green body" preform |

| 3. Sintering | Heat to 360-380°C (680-716°F) | Fuse particles to create a solid, strong part |

| 4. Controlled Cooling | Cool slowly to room temperature | Lock in structure and prevent warping/cracking |

Need a reliable partner for your PTFE components?

KINTEK specializes in precision PTFE compression molding, manufacturing high-performance seals, liners, and labware for the semiconductor, medical, and industrial sectors. Our strict process control ensures your parts have the consistent density, strength, and chemical resistance you require.

We offer custom fabrication from prototypes to high-volume orders. Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the three basic types of Teflon back-up rings? Choose the Right Design for Your Sealing System

- What type of valves are most suitable for highly corrosive or chemical industries? The Definitive Guide to PTFE Lined Butterfly Valves

- What are the advantages of PFA lined ball valves in chemical plants? Achieve Superior Chemical Resistance and Reliability

- How does the compressibility of ePTFE gaskets benefit sealing applications? Achieve Superior, Leak-Free Seals

- What types of applications are PTFE O-rings best suited for? Solve Sealing Challenges in Extreme Conditions

- How are PTFE bridge bearing pads installed on supporting pads? A Guide to Direct Bonding vs. Embedded Plates

- How does the non-absorbent nature of PTFE Teflon washers affect their performance? Ensure Long-Term Sealing Reliability

- What role do Teflon-encapsulated O-Rings play in the oil and gas and chemical processing industries? A Critical Sealing Solution