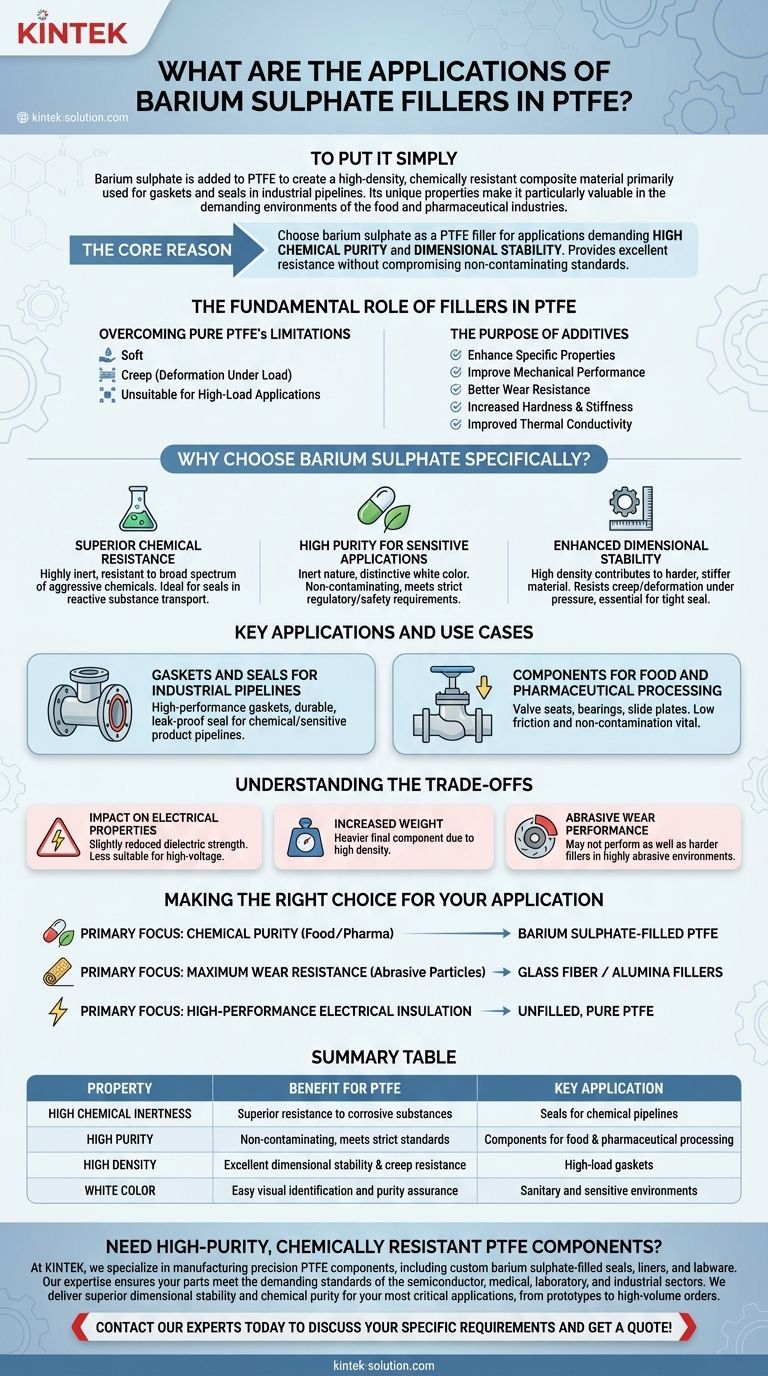

To put it simply, barium sulphate is added to PTFE to create a high-density, chemically resistant composite material primarily used for gaskets and seals in industrial pipelines. Its unique properties make it particularly valuable in the demanding environments of the food and pharmaceutical industries.

The core reason to choose barium sulphate as a PTFE filler is for applications demanding high chemical purity and dimensional stability. Unlike other fillers, it provides excellent resistance to a wide range of chemicals without compromising the non-contaminating standards required in sensitive industries.

The Fundamental Role of Fillers in PTFE

Overcoming Pure PTFE's Limitations

Polytetrafluoroethylene (PTFE), known by the brand name Teflon, is remarkably non-reactive and has a very low coefficient of friction. However, pure PTFE is relatively soft and suffers from creep, which is the tendency to slowly deform under a sustained load.

This deformation makes pure PTFE unsuitable for high-load applications like gaskets or structural components, where maintaining a precise shape is critical.

The Purpose of Additives

Fillers are materials added to the PTFE base resin to enhance specific properties. By integrating materials like barium sulphate, engineers can create a composite that retains PTFE's core benefits while dramatically improving its mechanical performance.

Common enhancements from fillers include significantly better wear resistance, increased hardness and stiffness, and improved thermal conductivity.

Why Choose Barium Sulphate Specifically?

While many fillers exist, including glass, carbon, and stainless steel, barium sulphate is selected for a distinct set of characteristics.

Superior Chemical Resistance

Barium sulphate is highly inert, making it resistant to a broad spectrum of aggressive chemicals. This makes it an ideal choice for seals and pipework components that transport reactive or corrosive substances.

High Purity for Sensitive Applications

Its inert nature and distinctive white color are critical in the pharmaceutical and food processing industries. The material does not leach or contaminate the products it comes into contact with, ensuring it meets strict regulatory and safety requirements.

Enhanced Dimensional Stability

As the references note, barium sulphate-filled PTFE has a high density. This contributes to a harder, stiffer material with much greater resistance to creep and deformation under pressure, which is essential for maintaining a tight seal in pipeline gaskets.

Key Applications and Use Cases

Gaskets and Seals for Industrial Pipelines

The primary application is in creating high-performance gaskets and seals for use in steel or stainless steel pipelines. These components provide a durable, leak-proof seal in systems transporting chemicals or sensitive products.

Components for Food and Pharmaceutical Processing

Because of its purity, barium sulphate-filled PTFE is used for various components within processing equipment. This can include valve seats, bearings, and slide plates where both low friction and non-contamination are vital.

Understanding the Trade-offs

No engineering material is perfect. Choosing a filled PTFE involves balancing benefits with potential downsides.

Impact on Electrical Properties

Pure PTFE is an exceptional electrical insulator. Adding mineral fillers like barium sulphate can slightly reduce the material's dielectric strength, making it less suitable for high-voltage electrical applications.

Increased Weight

The high density that improves stability also results in a heavier final component compared to pure PTFE or composites with lighter fillers like glass microspheres.

Abrasive Wear Performance

While its wear resistance is a major improvement over pure PTFE, it may not perform as well as harder fillers like alumina or glass fiber in highly abrasive environments. Its strength lies in chemical, not abrasive, resistance.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary operational demand.

- If your primary focus is chemical purity for food or pharma: Barium sulphate-filled PTFE is an excellent choice for seals and gaskets.

- If your primary focus is maximum wear resistance against abrasive particles: Consider a composite with glass fiber or alumina fillers.

- If your primary focus is high-performance electrical insulation: Unfilled, pure PTFE remains the superior option.

Choosing the right PTFE filler is about precisely matching the material's specific strengths to the demands of your engineering challenge.

Summary Table:

| Property | Benefit for PTFE | Key Application |

|---|---|---|

| High Chemical Inertness | Superior resistance to corrosive substances | Seals for chemical pipelines |

| High Purity | Non-contaminating, meets strict industry standards | Components for food & pharmaceutical processing |

| High Density | Excellent dimensional stability & creep resistance | High-load gaskets |

| White Color | Easy visual identification and purity assurance | Sanitary and sensitive environments |

Need high-purity, chemically resistant PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom barium sulphate-filled seals, liners, and labware. Our expertise ensures your parts meet the demanding standards of the semiconductor, medical, laboratory, and industrial sectors.

We deliver superior dimensional stability and chemical purity for your most critical applications, from prototypes to high-volume orders.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining