The fundamental advantage of PTFE/Teflon is its extreme inertness. This single characteristic, born from its powerful carbon-fluorine bonds, is the source of its most valued properties: near-total chemical resistance, an incredibly low coefficient of friction, high thermal stability, and excellent dielectric insulation. These attributes make it one of the most versatile and reliable problem-solving materials in modern engineering.

While famous for the non-stick surface on cookware, PTFE's true industrial value lies in its chemical and thermal stability. These core properties create a cascade of benefits, leading to unparalleled durability, efficiency, and safety in the most demanding environments.

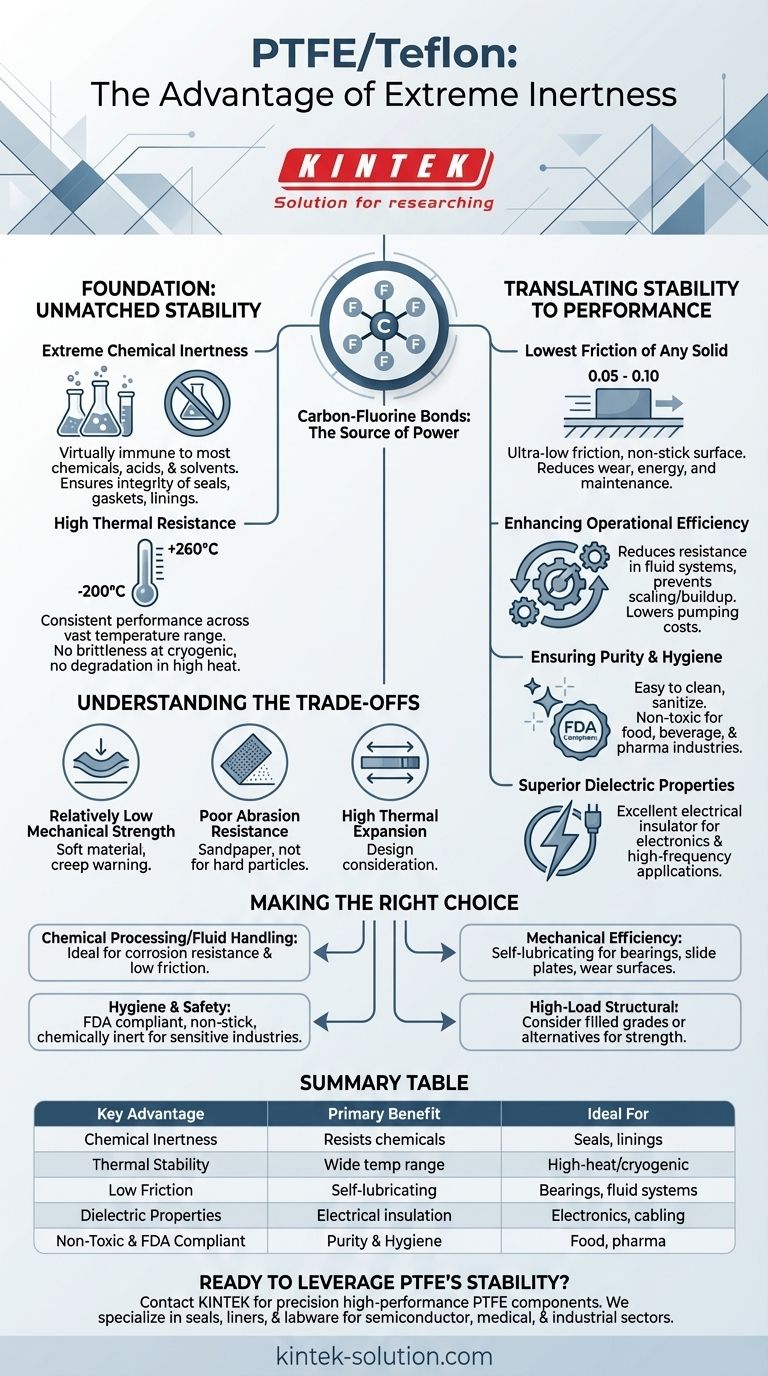

The Foundation: Unmatched Chemical and Thermal Stability

The primary benefits of PTFE all stem from its unique molecular structure, which makes it exceptionally stable and non-reactive.

### Extreme Chemical Inertness

PTFE is virtually immune to almost all industrial chemicals, acids, and solvents. This makes it an essential material for components that handle corrosive substances.

This property ensures the integrity and longevity of parts like seals, gaskets, and pipe linings, preventing system failure and contamination.

### High Thermal Resistance

It performs consistently across a vast temperature range, typically from -325 °F to +500 °F (-200 °C to +260 °C).

Unlike other polymers, PTFE does not become brittle at cryogenic temperatures or degrade in high-heat applications, ensuring reliable performance under extreme thermal stress.

### Resistance to Aging and Weathering

PTFE does not degrade or become brittle over time when exposed to the elements, including moisture and UV radiation. This gives components an exceptionally long service life and shelf-life.

Translating Stability into Performance

This inherent stability gives rise to a set of performance characteristics that directly improve operational efficiency, safety, and reliability.

### The Lowest Friction of Any Solid

PTFE has one of the lowest coefficients of friction of any known solid material, with a value typically between 0.05 and 0.10.

This is the source of its famous non-stick quality. Materials, whether sticky foods or industrial sludge, have immense difficulty adhering to its surface.

### Enhancing Operational Efficiency

This ultra-low friction significantly reduces wear and tear on moving parts, extending the life of machinery and reducing the need for liquid lubricants.

In fluid systems, PTFE-lined pipes lower resistance, which reduces the energy (and cost) required for pumping. Its non-stick nature also prevents scaling or deposit buildup, maintaining smooth flow and minimizing maintenance.

### Ensuring Purity and Hygiene

Because it is chemically inert and non-stick, PTFE is incredibly easy to clean and sanitize.

It is also non-toxic and FDA-compliant for food contact, making it a default choice for the food, beverage, and pharmaceutical industries where purity and safety are critical.

### Superior Dielectric Properties

PTFE is an excellent electrical insulator with high dielectric strength and low dissipation, making it ideal for high-frequency applications in electronics and cabling.

Understanding the Trade-offs

No material is perfect. To use PTFE effectively, it's critical to understand its limitations.

### Relatively Low Mechanical Strength

PTFE is a relatively soft material. It is not suitable for high-load structural applications on its own, as it can be subject to creep and deformation under constant pressure.

### Poor Abrasion Resistance

While it has low friction, PTFE is not exceptionally hard. It can be worn down by abrasive particles, making it less ideal for high-wear environments with hard contaminants.

### High Thermal Expansion

It has a higher coefficient of thermal expansion than most metals. This must be accounted for in designs where tight tolerances are required across a wide temperature range.

Making the Right Choice for Your Application

Selecting PTFE is a decision for reliability in specific contexts. Use its strengths where they matter most.

- If your primary focus is chemical processing or fluid handling: PTFE's corrosion resistance and low-friction surface make it ideal for linings, seals, and gaskets to ensure system longevity and purity.

- If your primary focus is mechanical efficiency: Its self-lubricating properties are invaluable for bearings, slide plates, and wear surfaces that reduce energy consumption and maintenance.

- If your primary focus is hygiene and safety: Its FDA compliance, non-stick surface, and chemical inertness make it a standard-bearer for equipment in the food, beverage, and pharmaceutical industries.

- If your primary focus is a high-load structural component: You should consider filled grades of PTFE (like glass or carbon-filled) or alternative engineering plastics to meet strength requirements.

Ultimately, choosing PTFE means prioritizing unmatched stability where chemical, thermal, and surface properties are non-negotiable.

Summary Table:

| Key Advantage | Primary Benefit | Ideal For |

|---|---|---|

| Extreme Chemical Inertness | Resists virtually all chemicals and solvents | Seals, gaskets, linings in corrosive environments |

| High Thermal Stability | Performs from -200°C to +260°C | High-heat and cryogenic applications |

| Lowest Coefficient of Friction | Self-lubricating and non-stick | Bearings, slide plates, fluid systems |

| Excellent Dielectric Properties | Superior electrical insulation | Electronics, high-frequency cabling |

| Non-Toxic & FDA Compliant | Ensures purity and hygiene | Food, beverage, pharmaceutical industries |

Ready to leverage the unmatched stability of PTFE for your most demanding applications?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components are fabricated to the highest standards, from prototypes to high-volume orders, delivering the reliability and purity your operations require.

Contact KINTEK today to discuss your specific needs and discover how our PTFE solutions can enhance your product's performance, safety, and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key chemical properties of PTFE that make it useful for cookware? Unlock Superior Non-Stick Performance

- What are the benefits of Teflon's softness? Unlock Superior Flexibility and Low-Friction Performance

- What types of PTFE products are available besides solid forms? Explore Flexible Tapes, Fabrics, and ePTFE

- How does PFA compare to FEP in terms of heat resistance and environmental effects? Choose the Right Fluoropolymer

- How does the low friction property of PTFE benefit industrial applications? Boost Efficiency & Durability

- What are the typical properties of virgin grade PTFE? Unmatched Chemical & Thermal Resistance

- How does PTFE react to common solvents? Discover Its Near-Total Chemical Immunity

- In which industries is PTFE/Teflon commonly used? Discover Its Critical Role in High-Performance Applications