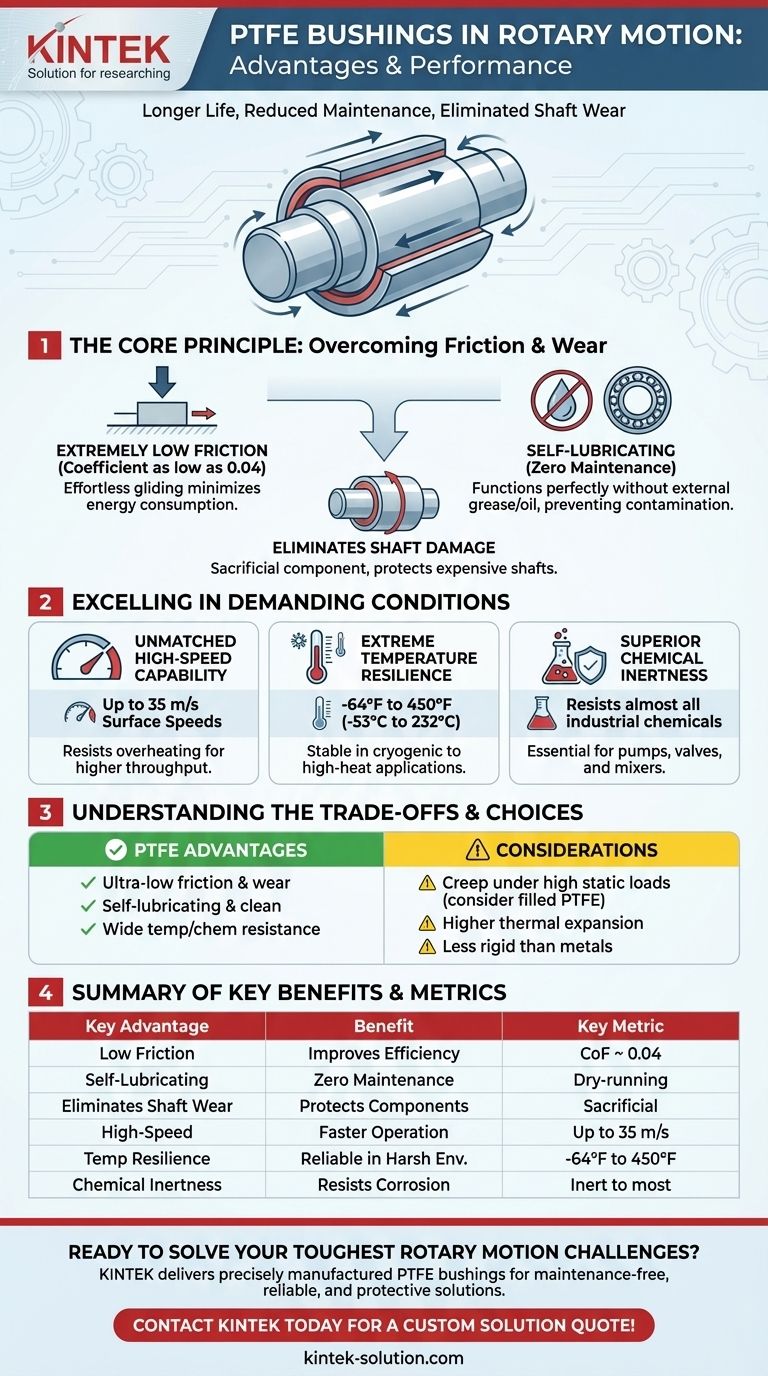

In short, PTFE bushings excel in rotary applications due to their unique combination of an extremely low-friction surface, the ability to run without any lubrication, and exceptional resistance to chemicals and temperature extremes. These properties result in longer component life, reduced maintenance, and the complete elimination of shaft wear caused by the bushing itself.

The core advantage of PTFE is not just its material properties, but its ability to solve critical operational problems. It enables high-performance, maintenance-free rotary systems that can function reliably in environments where conventional materials would quickly fail.

The Core Principle: Overcoming Friction and Wear

The fundamental challenges in any rotary system are friction, heat, and wear. PTFE addresses these issues at a molecular level, providing a robust solution where traditional lubricated metal or plastic bushings fall short.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, with values as low as 0.04.

This means it glides effortlessly over mating surfaces like a rotating shaft. This inherent slipperiness minimizes the energy required to turn the shaft, reducing power consumption and improving overall system efficiency.

Self-Lubricating for Zero Maintenance

Perhaps the most significant advantage is that PTFE is self-lubricating. It can function perfectly without any external grease or oil.

This "dry running" capability is revolutionary for applications where lubrication is undesirable or impossible. It eliminates routine maintenance schedules and prevents contamination from lubricants, which is critical in food processing, medical, and cleanroom environments.

Eliminating Shaft Damage

Traditional bushings, especially when lubrication fails, can gall and wear down the expensive shaft they are meant to protect.

Because PTFE is a softer material, it is designed to be the sacrificial component. The bushing itself will wear slowly over a long service life, leaving the more critical and costly shaft completely untouched.

Excelling in Demanding Operating Conditions

Beyond its frictional properties, PTFE's resilience allows it to perform in environments that would destroy other materials. This makes it a go-to choice for designers facing extreme operational challenges.

Unmatched High-Speed Capability

PTFE seals and bushings can handle shaft surface speeds up to 35 m/s.

This is significantly faster than many elastomers or other plastics can tolerate. Because PTFE generates very little frictional heat, it resists overheating and premature failure, enabling higher performance and greater throughput in high-speed machinery.

Extreme Temperature Resilience

PTFE maintains its integrity across a vast temperature range, typically from -64°F to 450°F (-53°C to 232°C).

This stability allows it to be used in applications ranging from cryogenic equipment to high-temperature industrial ovens and engines, where other polymers would become brittle or melt.

Superior Chemical Inertness

PTFE is inert to almost all industrial chemicals, solvents, and corrosive substances.

This makes it an essential material for pumps, valves, and mixers in the chemical processing, pharmaceutical, and oil and gas industries, ensuring reliable sealing and rotation even when exposed to aggressive media.

Understanding the Trade-offs

While its advantages are significant, PTFE is not a universal solution. An objective assessment requires understanding its limitations.

Considerations for High Loads

Virgin PTFE is a relatively soft material and can be susceptible to creep, or slow deformation under a constant heavy load. For high-load, low-speed applications, a metallic bushing like bronze may be more suitable.

The Role of Fillers

To counteract its softness, PTFE is often blended with additives like glass fiber, carbon, or graphite. These "filled PTFE" compounds enhance wear resistance, improve strength, and reduce creep, broadening its suitability for more demanding structural roles.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. Designers must account for this in high-precision applications, ensuring that proper clearances are maintained as operating temperatures fluctuate to prevent binding.

Making the Right Choice for Your Application

Selecting the right bushing material depends entirely on your primary engineering goal. PTFE offers distinct solutions for specific challenges.

- If your primary focus is reducing maintenance and contamination: PTFE is the ideal choice due to its self-lubricating, dry-running capability and compliance with USDA/FDA standards.

- If your primary focus is maximizing rotational speed and efficiency: PTFE's ultra-low friction minimizes heat buildup and power loss, allowing machinery to run faster and more effectively.

- If your primary focus is reliability in extreme environments: PTFE's unmatched chemical and temperature resistance ensures operational integrity where other materials would degrade and fail.

- If your primary focus is handling high static loads with minimal rotation: You may need to consider a filled PTFE compound or a more rigid material like a metallic bushing.

Ultimately, choosing PTFE is an investment in operational resilience and long-term performance for your most challenging rotary systems.

Summary Table:

| Key Advantage | Benefit | Key Metric |

|---|---|---|

| Extremely Low Friction | Reduces power consumption, improves efficiency | Coefficient of friction as low as 0.04 |

| Self-Lubricating | Enables zero-maintenance, dry-running operation | Eliminates lubricant contamination |

| Eliminates Shaft Wear | Protects critical components, reduces costs | Acts as a sacrificial, long-wearing component |

| High-Speed Capability | Supports faster machinery operation | Handles surface speeds up to 35 m/s |

| Extreme Temperature Resilience | Functions reliably in harsh environments | Stable from -64°F to 450°F (-53°C to 232°C) |

| Superior Chemical Inertness | Resists degradation from corrosive substances | Ideal for chemical, pharmaceutical, and oil & gas industries |

Ready to Solve Your Toughest Rotary Motion Challenges?

PTFE bushings from KINTEK are engineered to deliver unmatched performance in demanding applications. We provide precisely manufactured PTFE components—including seals, liners, and custom bushings—that offer:

- Maintenance-Free Operation: Eliminate lubrication schedules and prevent contamination in cleanroom, medical, and food processing environments.

- Enhanced Reliability: Ensure long-lasting performance in extreme temperatures and corrosive conditions common in semiconductor, industrial, and laboratory settings.

- Protection for Critical Components: Our bushings are designed to be the sacrificial part, preserving your expensive shafts and machinery.

Whether you need a custom prototype or high-volume production, KINTEK prioritizes precision and durability. Let our expertise in PTFE fabrication help you build more resilient and efficient systems.

Contact KINTEK today to discuss your specific application requirements and receive a custom solution quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments