In short, PTFE (Polytetrafluoroethylene) fundamentally improves ball valve performance by providing a superior seal, dramatically extending the valve's service life, and minimizing maintenance requirements. Its unique combination of chemical inertness, low friction, and flexibility allows it to outperform many other sealing materials in demanding industrial applications.

The core reason PTFE is a superior sealing material is its dual resistance to both chemical attack and physical wear. Its near-total chemical immunity prevents degradation, while its exceptionally low friction minimizes the mechanical stress that causes other seals to fail over time.

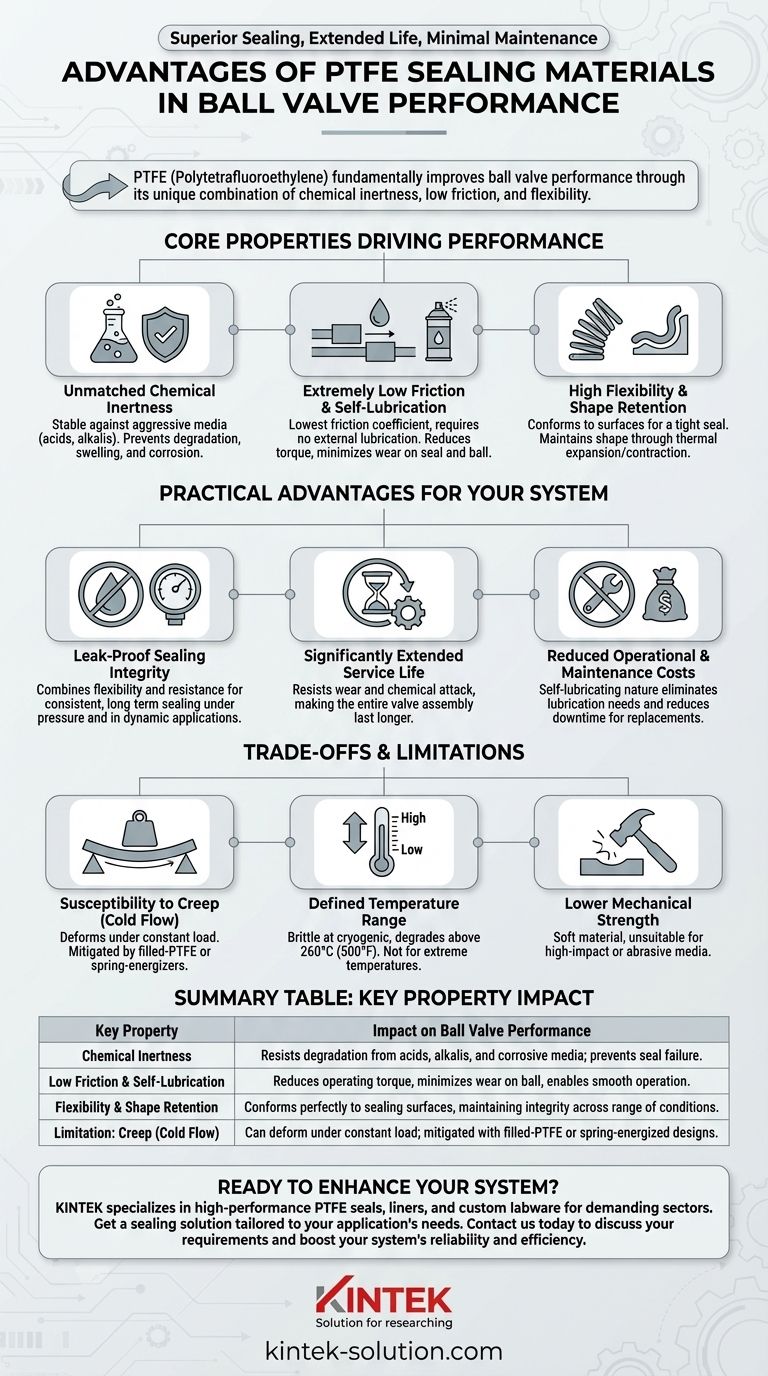

The Core Properties That Drive Performance

To understand why PTFE is so effective, we must look at its intrinsic material properties. These characteristics work together to solve the most common failure points in valve sealing.

Unmatched Chemical Inertness

PTFE is one of the most chemically resistant materials known. It remains stable and effective when exposed to a wide range of aggressive media, including strong acids and alkalis.

This property ensures the seal will not degrade, swell, or corrode, preventing leaks even in the harshest chemical environments.

Extremely Low Friction and Self-Lubrication

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This means it is inherently slippery and requires no external lubrication.

This self-lubricating nature drastically reduces the torque needed to open and close the valve, allowing for faster, smoother, and shock-free operation. More importantly, it minimizes wear on both the seal and the ball surface.

High Flexibility and Shape Retention

The material is highly flexible, allowing it to conform perfectly to the surfaces of the ball and valve body, creating an exceptionally tight seal.

Furthermore, PTFE maintains its shape well during thermal expansion and contraction, ensuring the seal remains effective across a range of operating temperatures. This is critical for preventing leaks in systems with fluctuating temperatures.

Translating Properties into Practical Advantages

These fundamental properties deliver tangible, real-world benefits in the performance and reliability of ball valves.

Leak-Proof Sealing Integrity

The combination of flexibility and chemical resistance means PTFE seals maintain their integrity over long periods. They form a tight, consistent barrier that effectively prevents medium leakage, even under pressure or in dynamic applications with rotating shafts.

Significantly Extended Service Life

Because PTFE seals resist both chemical degradation and physical wear, they last much longer than seals made from other materials. This durability makes the entire valve assembly less prone to aging and failure, directly extending its operational lifespan.

Reduced Operational and Maintenance Costs

Valves with PTFE seals are often described as "maintenance-free." The self-lubricating property eliminates the need for periodic lubrication, and the long service life reduces the frequency of costly downtime for seal replacement.

Understanding the Trade-offs and Limitations

While highly effective, PTFE is not without its limitations. Acknowledging these is key to proper application and engineering.

Susceptibility to Creep (Cold Flow)

The primary weakness of pure PTFE is its tendency to "creep" or deform permanently when subjected to a constant load over time. This can eventually compromise sealing integrity in high-pressure applications.

To counteract this, engineers often use filled-PTFE (mixed with materials like glass or carbon) or design seals with spring-energizers (like the mentioned V-ring packing) that provide a constant mechanical force to maintain the seal's shape.

Defined Temperature Range

Although PTFE has good temperature resistance, it has clear operational limits. It can become brittle at cryogenic temperatures and can begin to degrade at very high temperatures (typically above 260°C or 500°F), releasing harmful fumes.

Lower Mechanical Strength

Compared to metals or harder polymers, PTFE is a relatively soft material. It is not suitable for applications involving high-impact or abrasive media, which can cause mechanical damage to the seal surface.

Making the Right Choice for Your Application

Selecting the right seal depends entirely on the operational demands of your system.

- If your primary focus is handling corrosive chemicals: PTFE's unparalleled chemical inertness provides the most reliable and safe long-term sealing solution.

- If your primary focus is minimizing maintenance and operational torque: The self-lubricating, low-friction nature of PTFE is your greatest asset, ensuring smooth operation and reducing service needs.

- If your primary focus is high-pressure or fluctuating temperatures: Consider a spring-energized or filled-PTFE seal to counteract creep and ensure a consistent, tight seal under load.

Ultimately, understanding these properties allows you to leverage PTFE not just as a component, but as a strategic choice for enhancing system reliability and efficiency.

Summary Table:

| Key Property | Impact on Ball Valve Performance |

|---|---|

| Chemical Inertness | Resists degradation from acids, alkalis, and corrosive media, preventing seal failure and leaks. |

| Low Friction & Self-Lubrication | Reduces operating torque, minimizes wear on the ball, and enables smooth, shock-free operation. |

| Flexibility & Shape Retention | Conforms perfectly to sealing surfaces, maintaining integrity across a range of temperatures and pressures. |

| Limitation: Creep (Cold Flow) | Can deform under constant load; mitigated with filled-PTFE or spring-energized designs for high-pressure use. |

Ready to enhance your ball valve performance with precision PTFE seals?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals, liners, and custom labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution perfectly tailored to your application's demands, whether you need superior chemical resistance, reduced maintenance, or extended service life.

Contact KINTEK today to discuss your specific requirements and let our experts provide a solution that boosts your system's reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some general applications of PTFE with fillers? Enhance Performance in Demanding Seals & Bearings

- What recent advancements have been made in PTFE expansion joint technology? Enhance Durability & Precision

- How are Teflon-encapsulated O-Rings utilized in heavy equipment and hydraulics? Achieve Superior Sealing and Reduce Downtime

- What are the advantages of using PTFE rotary seals over rubber elastomer seals? Superior Performance in Extreme Conditions

- What are the main benefits of using PTFE liners? Achieve Unmatched Chemical and Thermal Resistance

- What are some everyday uses of Teflon sheets? From Cookware to Cars, Discover Its Hidden Role

- What are the tolerance specifications for the thickness of PTFE disks? Why ±20% is the Industry Standard

- How does the low friction property of PTFE benefit O-rings? Extend Seal Life and Boost Efficiency