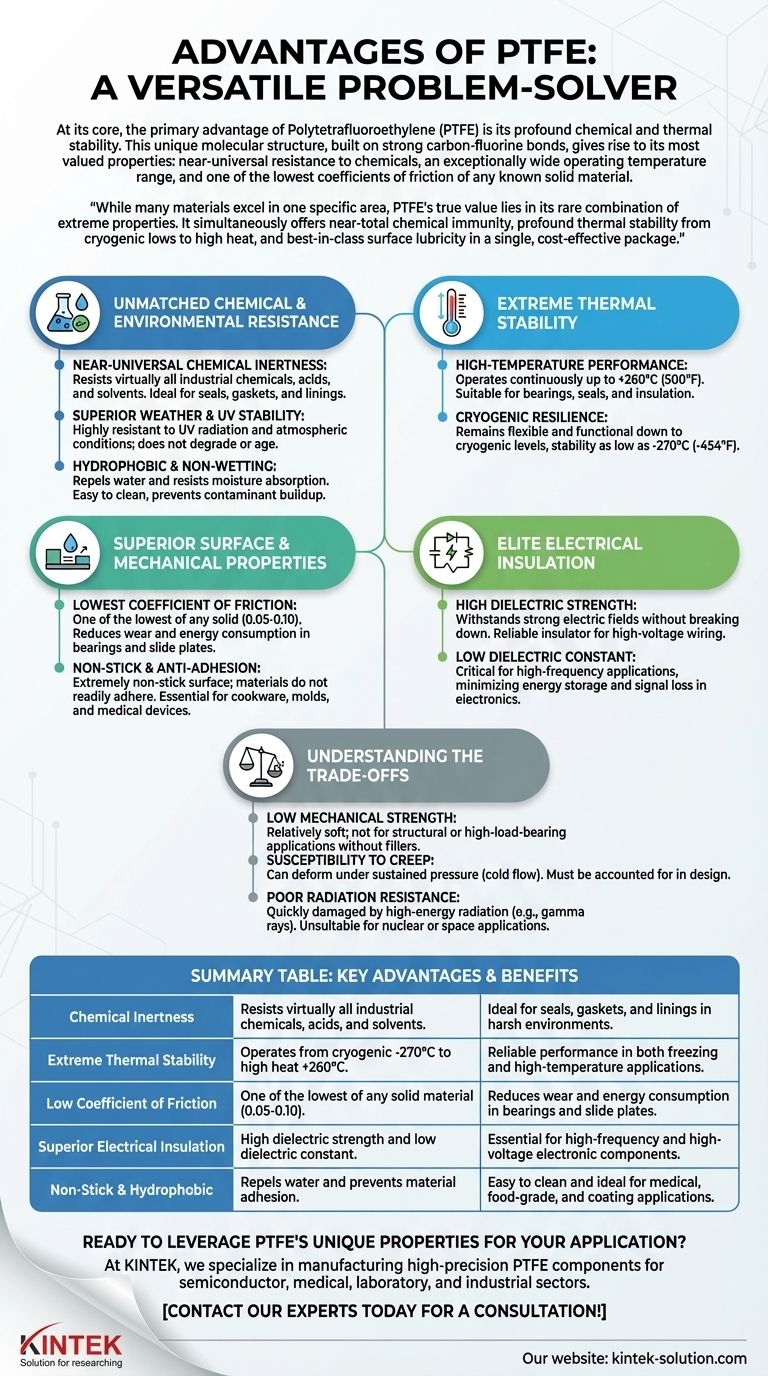

At its core, the primary advantage of Polytetrafluoroethylene (PTFE) is its profound chemical and thermal stability. This unique molecular structure, built on strong carbon-fluorine bonds, gives rise to its most valued properties: near-universal resistance to chemicals, an exceptionally wide operating temperature range, and one of the lowest coefficients of friction of any known solid material. These core traits, combined with excellent electrical insulation and biocompatibility, make it a uniquely versatile problem-solver in demanding environments.

While many materials excel in one specific area, PTFE's true value lies in its rare combination of extreme properties. It simultaneously offers near-total chemical immunity, profound thermal stability from cryogenic lows to high heat, and best-in-class surface lubricity in a single, cost-effective package.

Unmatched Chemical and Environmental Resistance

One of the most defining characteristics of PTFE is its ability to withstand harsh environments that would degrade most other materials. This resilience stems from its fundamental chemical makeup.

Near-Universal Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of industrial chemicals, solvents, acids, and bases. This makes it an essential material for seals, gaskets, linings, and fluid-handling components in the chemical processing and manufacturing industries.

Superior Weather and UV Stability

Unlike many plastics that become brittle or discolor with exposure to sunlight and weather, PTFE is highly resistant to UV radiation and atmospheric conditions. It does not degrade, embrittle, or age over long periods of outdoor exposure, ensuring longevity and reliability.

Hydrophobic and Non-Wetting

PTFE is hydrophobic, meaning it actively repels water and resists moisture absorption. This property, combined with its non-stick nature, makes it easy to clean and prevents the buildup of contaminants, which is critical in food-grade and medical applications.

Extreme Thermal Stability

PTFE maintains its integrity and performance across a remarkably broad spectrum of temperatures, outperforming nearly all other fluoropolymers.

High-Temperature Performance

PTFE can operate continuously at temperatures up to +260°C (500°F) without significant degradation of its physical properties. This makes it suitable for high-temperature bearings, seals, and electrical insulation.

Cryogenic Resilience

Equally impressive is its performance at extremely low temperatures. PTFE remains flexible and functional down to cryogenic levels, with some sources citing stability at temperatures as low as -270°C (-454°F), where other materials would shatter.

Superior Surface and Mechanical Properties

The surface of PTFE is unique in the materials world, leading to its most well-known applications, such as non-stick coatings.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid, often compared to wet ice on wet ice, with values between 0.05 and 0.10. This extreme lubricity reduces wear and energy consumption in mechanical applications like slide plates, gears, and self-lubricating bearings.

Non-Stick and Anti-Adhesion

The same low surface energy that creates low friction also makes PTFE exceptionally non-stick. Materials do not readily adhere to its surface, a property essential not only for cookware but also for industrial molds, process rollers, and medical devices.

Elite Electrical Insulation

PTFE is a premier electrical insulator, trusted in demanding electronics and high-frequency applications where signal integrity is paramount.

High Dielectric Strength

It has a very high dielectric strength, meaning it can withstand a strong electric field without breaking down. This makes it a reliable insulator for high-voltage wiring and components.

Low Dielectric Constant

Critically for high-frequency applications, PTFE has a very low dielectric constant. This ensures that minimal electrical energy is stored in the material, preventing signal loss in coaxial cables, circuit boards, and other sensitive electronic parts.

Understanding the Trade-offs

No material is perfect, and its extreme properties introduce practical limitations. Being a trusted advisor means acknowledging these realities.

Low Mechanical Strength

Compared to engineering plastics like nylon or PEEK, virgin PTFE is a relatively soft material. It has low tensile strength and is not suitable for most structural or high-load-bearing applications without reinforcement from fillers like glass or carbon.

Susceptibility to Creep

Under sustained pressure (compressive load), PTFE can deform over time. This phenomenon, known as "creep" or cold flow, must be accounted for when designing components like seals and gaskets to ensure long-term performance.

Poor Radiation Resistance

PTFE is quickly damaged by high-energy radiation (such as gamma rays). This makes it unsuitable for many applications in the nuclear industry or in space environments with high radiation levels.

Making the Right Choice for Your Application

Selecting PTFE should be a decision based on its unique strengths aligned with your specific goal.

- If your primary focus is sealing aggressive chemicals or operating in extreme temperatures: PTFE's chemical and thermal stability make it an ideal choice for gaskets, O-rings, and vessel linings.

- If your primary focus is reducing friction and wear: Its unparalleled lubricity is perfect for creating self-lubricating bearings, slide plates, and high-performance, non-stick coatings.

- If your primary focus is high-frequency electrical insulation: Its low dielectric constant and high resistance are critical for specialized wiring, connectors, and circuit board substrates.

- If your primary focus is structural strength under high load: You should specify a filled grade of PTFE (e.g., carbon-filled) or consider an entirely different engineering material.

By understanding this unique balance of elite properties and practical limitations, you can leverage PTFE to solve some of the most demanding engineering challenges.

Summary Table:

| Key Advantage | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, acids, and solvents. | Ideal for seals, gaskets, and linings in harsh environments. |

| Extreme Thermal Stability | Operates from cryogenic -270°C to high heat +260°C. | Reliable performance in both freezing and high-temperature applications. |

| Low Coefficient of Friction | One of the lowest of any solid material (0.05-0.10). | Reduces wear and energy consumption in bearings and slide plates. |

| Superior Electrical Insulation | High dielectric strength and low dielectric constant. | Essential for high-frequency and high-voltage electronic components. |

| Non-Stick & Hydrophobic | Repels water and prevents material adhesion. | Easy to clean and ideal for medical, food-grade, and coating applications. |

Ready to leverage PTFE's unique properties for your application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our expertise ensures you get a component that perfectly balances PTFE's elite properties with the practical demands of your project.

Let's discuss how our PTFE solutions can solve your most demanding engineering challenges. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What is the temperature resistance of Teflon? Master Its Performance from -200°C to 260°C

- What makes PTFE an ideal material for corrosion-resistant applications? Unmatched Chemical Inertness for Harsh Environments

- What are the key properties of PTFE plastic? Harness Extreme Chemical & Thermal Resistance

- How is PTFE used in the food and beverage industry? Ensuring Purity and Efficiency in Production

- How does PTFE resist chemical attacks? The Science Behind Its Unmatched Chemical Inertness

- What are the friction and surface properties of PTFE? Discover the Science Behind Its Low Friction & Non-Stick Performance

- What materials are needed to synthesize PTFE? A Guide to the Core Ingredients and Process

- What are the general characteristics of PTFE as a material? Unmatched Performance in Extreme Conditions