To put it simply, the primary advantages of graphite packing over PTFE packing are its superior performance in high-temperature environments and high-speed applications. Its natural self-lubricating properties and high thermal conductivity allow it to handle operational stresses that would cause PTFE to fail.

The choice between graphite and PTFE packing is not a question of which is universally better, but which is correct for your specific operating conditions. Graphite is the definitive choice for thermal and dynamic stress, while PTFE excels in applications where its higher tensile strength is required.

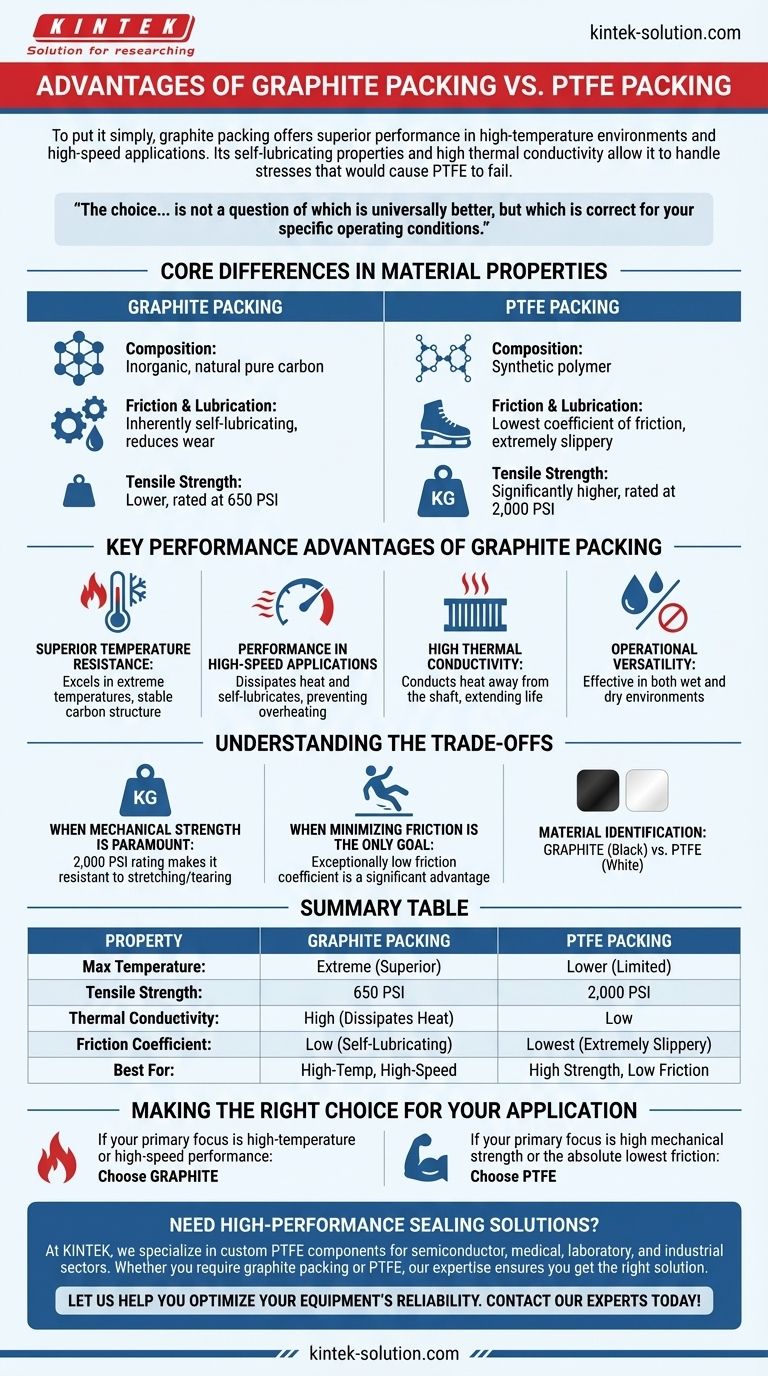

Core Differences in Material Properties

To understand the advantages of each, we must first look at their fundamental differences. These materials originate from entirely different sources, which dictates their performance characteristics.

### Composition: Natural Carbon vs. Synthetic Polymer

Graphite is an inorganic, natural form of pure carbon. This composition is the source of its thermal stability.

PTFE (polytetrafluoroethylene) is a synthetic polymer, which gives it different mechanical properties, such as a higher tensile strength.

### Friction and Lubrication

Graphite packing is inherently self-lubricating. This property reduces friction and wear on shafts, especially during startup and in dry-run conditions.

While graphite has a low coefficient of friction, PTFE has the lowest coefficient of friction of any solid material, making it extremely slippery.

### Tensile Strength

PTFE packing has a significantly higher tensile strength, rated at 2,000 PSI.

Graphite packing has a lower tensile strength, rated at 650 PSI. This makes PTFE mechanically stronger under tension.

Key Performance Advantages of Graphite Packing

Graphite's inherent properties make it the ideal solution for demanding industrial environments where heat and speed are primary concerns.

### Superior Temperature Resistance

Graphite excels in extreme temperatures, both high and low. Its carbon structure remains stable where a synthetic polymer like PTFE would degrade or become brittle.

### Performance in High-Speed Applications

For equipment with high shaft speeds, graphite is the preferred choice. Its ability to dissipate heat and self-lubricate prevents overheating and premature wear.

### High Thermal Conductivity

A key advantage of graphite is its ability to conduct heat away from the shaft. This prevents heat buildup at the sealing point, extending the life of both the packing and the equipment.

### Operational Versatility

Graphite packing is effective in both wet and dry environments, providing a reliable seal without requiring a liquid medium for lubrication.

Understanding the Trade-offs

Choosing graphite is not without trade-offs. While it excels under heat and speed, PTFE holds distinct advantages in other areas that may be critical for your application.

### When Mechanical Strength is Paramount

If your application requires high tensile strength, PTFE is the clear winner. Its 2,000 PSI rating makes it far more resistant to stretching and tearing than graphite.

### When Minimizing Friction is the Only Goal

For applications that are extremely sensitive to friction, PTFE's exceptionally low friction coefficient is a significant advantage over graphite, even though both perform well.

### Material Identification

The materials are also visually distinct. Graphite packing is black, while PTFE packing is white. This can be a factor in environments where process cleanliness and contamination control are critical.

Making the Right Choice for Your Application

Your final decision must be guided by the primary demands of your equipment and process.

- If your primary focus is high-temperature or high-speed performance: Choose graphite for its unmatched thermal stability and self-lubricating properties.

- If your primary focus is high mechanical strength or the absolute lowest friction: Choose PTFE for its superior tensile strength and exceptionally slippery surface.

Understanding these core material differences empowers you to select the precise packing that ensures reliability and longevity for your equipment.

Summary Table:

| Property | Graphite Packing | PTFE Packing |

|---|---|---|

| Max Temperature | Extreme (Superior) | Lower (Limited) |

| Tensile Strength | 650 PSI | 2,000 PSI |

| Thermal Conductivity | High (Dissipates Heat) | Low |

| Friction Coefficient | Low (Self-Lubricating) | Lowest (Extremely Slippery) |

| Best For | High-Temp, High-Speed | High Strength, Low Friction |

Need High-Performance Sealing Solutions?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require graphite packing for extreme temperatures or PTFE packing for superior mechanical strength, our expertise in custom fabrication from prototypes to high-volume orders ensures you get the right solution for your application.

Let us help you optimize your equipment's reliability and longevity. Contact our experts today for a tailored consultation!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What are PTFE seals and why are they considered a reliable solution for extreme environments? Engineered for Harsh Conditions

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals