In essence, a spring-energized Teflon seal is a high-performance sealing device designed to succeed where conventional elastomeric seals, like rubber O-rings, fail. It consists of a polymer jacket, typically made of PTFE (Teflon), and an internal metallic spring that provides a constant load, ensuring a reliable seal in demanding conditions.

This type of seal is not a general-purpose replacement for standard seals; it is a specialized problem-solver engineered for extreme environments involving aggressive chemicals, wide temperature ranges, high pressures, or low-friction requirements.

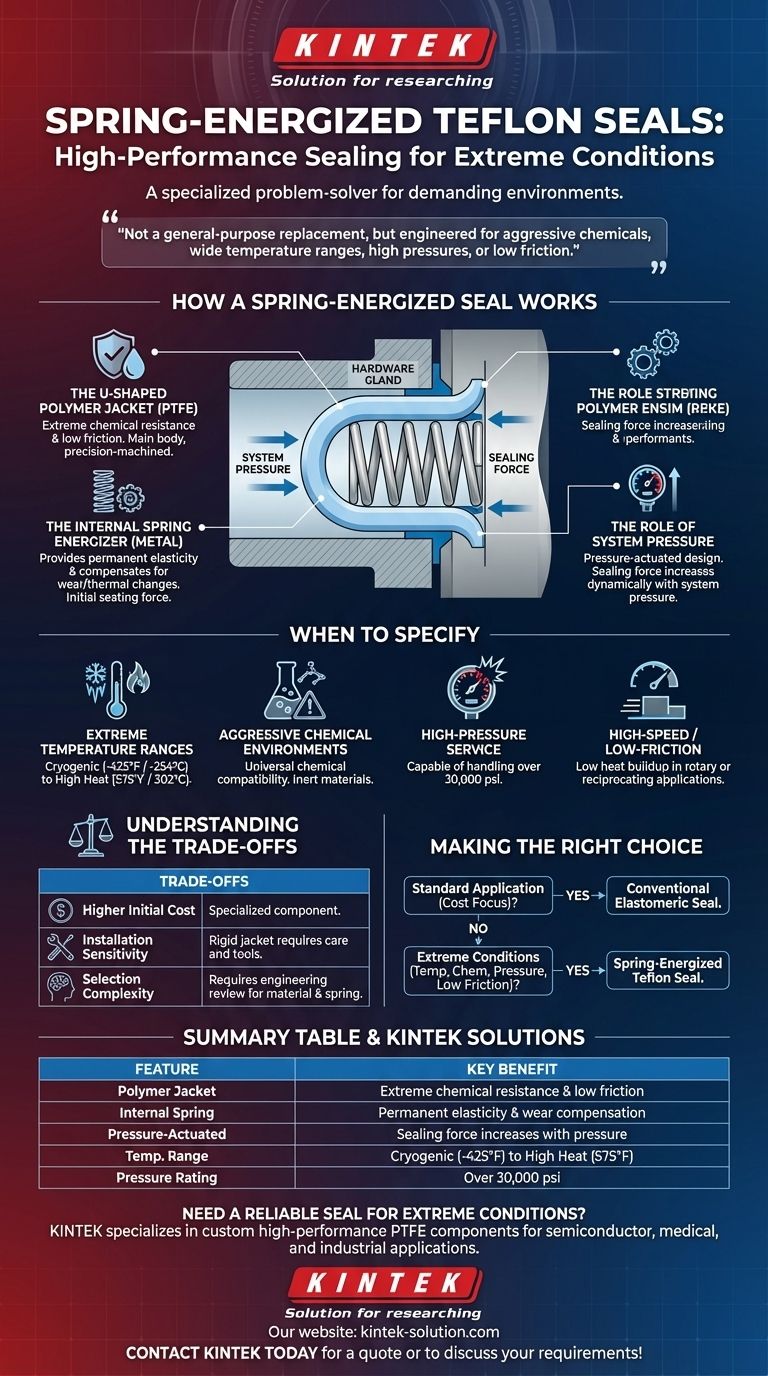

How a Spring-Energized Seal Works

The effectiveness of these seals comes from the synergy of their three core design elements: the jacket, the spring, and the system pressure itself.

The U-Shaped Polymer Jacket

The main body of the seal is a precision-machined U-shaped jacket made from a high-performance polymer, most commonly PTFE (polytetrafluoroethylene), often referred to by its brand name, Teflon.

This material provides the seal's primary benefits: extremely low friction and near-universal chemical resistance.

The Internal Spring Energizer

Inside the U-shaped jacket sits a metal spring. This spring provides the initial seating force, pushing the lips of the jacket outward to create a tight seal, even when system pressure is very low or absent.

Crucially, the spring provides permanent elasticity. It continuously compensates for material wear, thermal expansion or contraction, and prevents the "compression set" (permanent deformation) that plagues elastomeric seals over time.

The Role of System Pressure

These seals are pressure-actuated. The U-shape of the jacket is designed to use the system's own fluid or gas pressure to increase the sealing force.

As pressure increases, it acts on the inside of the "U," pushing the sealing lips more forcefully against the hardware surfaces, thus strengthening the seal dynamically.

When to Specify a Spring-Energized Seal

You should consider this type of seal when your application's operating conditions exceed the capabilities of standard elastomeric seals.

Extreme Temperature Ranges

Spring-energized seals operate reliably in conditions where elastomers would become brittle or degrade. They are rated for cryogenic service down to -425°F (-254°C) and high-temperature service up to 575°F (302°C).

Aggressive Chemical Environments

PTFE is one of the most chemically inert materials available. This makes these seals the default choice for applications involving aggressive solvents, acids, or other chemicals that would quickly destroy a standard rubber seal.

High-Pressure or High-Speed Service

The robust design allows these seals to handle extreme pressures, with some rated for over 30,000 psi. Furthermore, the low-friction nature of the PTFE jacket makes them ideal for high-speed rotary or reciprocating applications where heat buildup would be a major issue.

Understanding the Trade-offs

While powerful, these seals are specialized components with specific considerations. They are not a one-size-fits-all solution.

Higher Initial Cost

As a high-performance, multi-component part, a spring-energized seal is significantly more expensive than a simple O-ring or elastomeric U-cup. Their use must be justified by the severity of the application.

Installation Sensitivity

The PTFE jacket is more rigid than a flexible elastomer. Care must be taken during installation to avoid scratching or gouging the sealing lips, which can compromise performance. Proper installation tools and procedures are critical.

Seal Material and Spring Selection

The performance of the seal is highly dependent on choosing the right combination of jacket material and spring type. Factors like fluid compatibility, temperature, and pressure dictate the optimal configuration, requiring careful engineering review.

Making the Right Choice for Your Application

Selecting the correct seal requires you to weigh performance needs against complexity and cost.

- If your primary focus is cost-effectiveness for a standard application: A conventional elastomeric seal, such as an O-ring or urethane U-cup, is almost always the correct choice.

- If you are dealing with extreme temperatures, either cryogenic or high heat: A spring-energized seal is necessary, as elastomers will not survive.

- If your application involves aggressive chemicals or solvents: The universal chemical compatibility of a PTFE-jacketed seal makes it the safest and most reliable option.

- If your goal is minimizing friction for high-speed or sensitive systems: The inherently low friction of a spring-energized PTFE seal is its defining advantage.

Ultimately, choosing a spring-energized seal is a decision to invest in reliability and performance when the operational demands are simply too great for conventional solutions.

Summary Table:

| Feature | Key Benefit |

|---|---|

| Polymer Jacket (PTFE) | Extreme chemical resistance & low friction |

| Internal Spring | Permanent elasticity & compensates for wear |

| Pressure-Actuated Design | Sealing force increases with system pressure |

| Temperature Range | Cryogenic (-425°F) to High Heat (575°F) |

| Pressure Rating | Capable of handling over 30,000 psi |

Need a reliable seal for extreme conditions?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom spring-energized seals. Our precision production ensures your seals will perform reliably in the most demanding semiconductor, medical, laboratory, and industrial applications.

We offer custom fabrication from prototypes to high-volume orders. Let our experts help you solve your toughest sealing challenges.

Contact KINTEK today for a quote or to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the tensile strength properties of PTFE? Leveraging Flexibility and Chemical Resistance

- What is fluid compatibility in ball valve seats? Ensure Reliable Sealing and Prevent Failure

- What are the strengths and weaknesses of bronze filled PTFE? Enhance Performance in Demanding Applications

- What are the installation requirements for PTFE Lined Butterfly Valves? Ensure Long-Term Reliability & Prevent Failure

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- How does temperature tolerance differ between NBR and PTFE seat materials? A Guide to Extreme Conditions

- What medical applications utilize PTFE ball bearings? Precision & Safety for Implants and Equipment

- Why might an engineer choose to stick with standard O-rings for long-running applications? Maximize Reliability & Minimize Risk