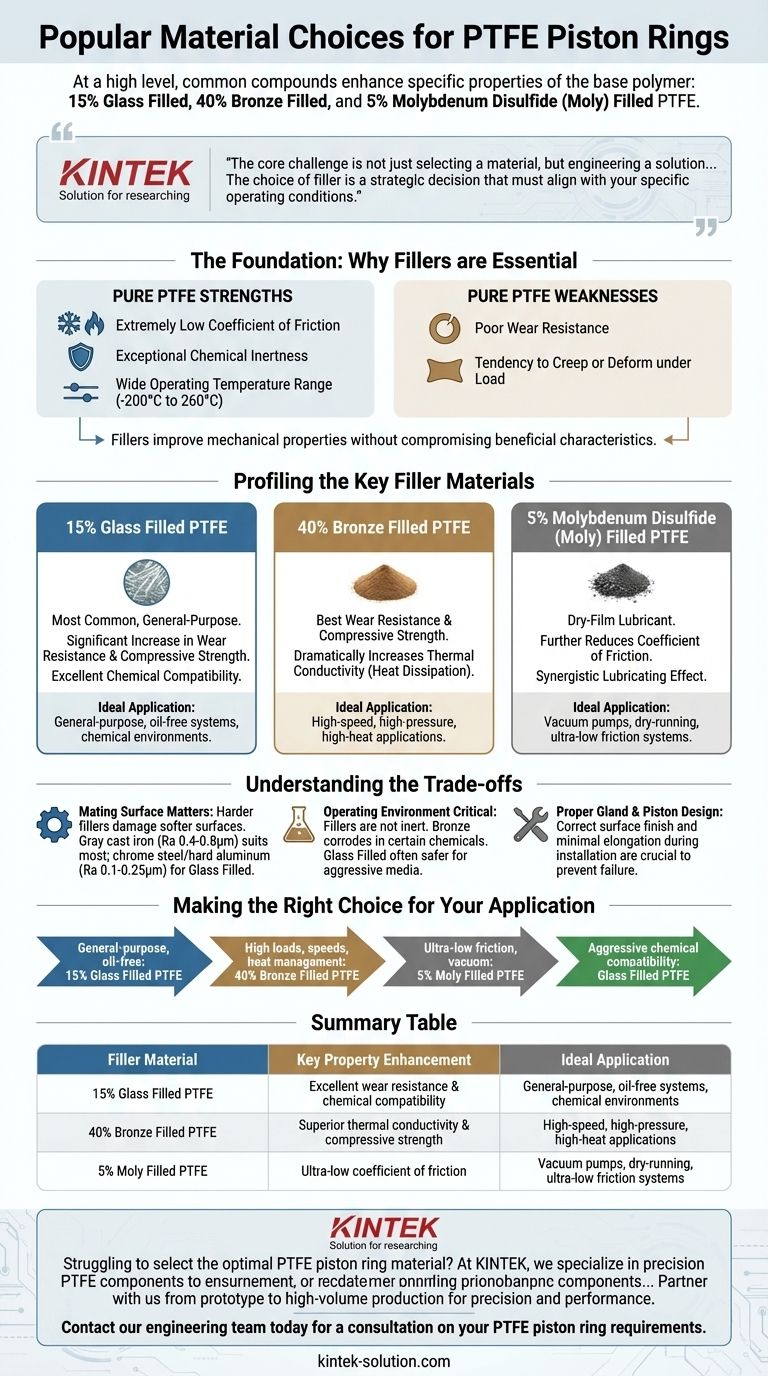

At a high level, the most popular material choices for PTFE piston rings are compounds designed to enhance specific properties of the base polymer. The three most common formulations are 15% Glass Filled PTFE, 40% Bronze Filled PTFE, and 5% Molybdenum Disulfide (Moly) Filled PTFE. Each filler is chosen to overcome the inherent limitations of pure PTFE in demanding applications.

The core challenge is not just selecting a material, but engineering a solution. While pure PTFE offers exceptional low friction and chemical resistance, it lacks the wear resistance and compressive strength needed for most piston ring applications. The choice of filler is a strategic decision that must align with your specific operating conditions, including the mating surface, operating pressures, and chemical environment.

The Foundation: Why Fillers are Essential

Pure Polytetrafluoroethylene (PTFE) is a remarkable polymer, but it is rarely sufficient on its own for dynamic sealing components like piston rings.

The Strengths of Pure PTFE

The base properties of PTFE make it an attractive starting point. It offers an extremely low coefficient of friction, making it ideal for reducing energy loss and for low-lubrication or oil-free systems.

It also has exceptional chemical inertness, resisting nearly all industrial chemicals, and a very wide operating temperature range, from cryogenic (-200°C) to high heat (260°C).

The Weaknesses of Pure PTFE

The primary limitations of pure PTFE are its poor wear resistance and its tendency to creep or deform under load. For a piston ring, which is constantly under pressure and sliding against a cylinder wall, these weaknesses would lead to a very short service life.

Fillers are added to the PTFE matrix to dramatically improve these mechanical properties without significantly compromising its beneficial friction and chemical characteristics.

Profiling the Key Filler Materials

Each filler imparts a distinct set of properties to the final compound. The choice depends entirely on the demands of the application.

15% Glass Filled PTFE

This is often considered the most common and general-purpose filled PTFE. The addition of glass fibers significantly increases wear resistance and compressive strength compared to virgin PTFE.

It maintains excellent chemical compatibility, making it a safe choice in a wide variety of fluid or gas environments. It is a well-balanced, cost-effective option for many applications.

40% Bronze Filled PTFE

Adding bronze powder creates a compound with the best wear resistance and compressive strength of the common fillers. Bronze also dramatically increases thermal conductivity.

This ability to dissipate heat makes it the premier choice for high-speed and high-pressure applications where frictional heat generation is a major concern.

5% Molybdenum Disulfide (Moly) Filled PTFE

Molybdenum disulfide (often called "Moly" or MoS₂) is a dry-film lubricant in its own right. Adding it to PTFE further reduces the coefficient of friction.

This compound is ideal for applications where minimizing friction is the absolute priority, such as in vacuum pumps or other systems where no lubrication can be present. It provides a synergistic lubricating effect with the PTFE.

Understanding the Trade-offs

Selecting a material in isolation is a common mistake. The piston ring is part of a system, and its interaction with other components is critical.

The Mating Surface Matters

The material of the cylinder or bore that the ring slides against is a crucial factor. A harder filler can damage a softer mating surface.

Gray cast iron offers good wear resistance with PTFE rings, but requires a specific surface roughness (Ra 0.4 to 0.8 µm).

For harder, smoother surfaces like chrome steel or hard-anodized aluminum (Ra 0.1 to 0.25 µm), a glass-filled PTFE may be perfectly suitable. Bronze-filled PTFE generally works well against harder steel surfaces.

The Operating Environment is Critical

While PTFE itself is nearly inert, the fillers are not. Bronze, for example, is susceptible to corrosion in certain chemical environments or in the presence of moisture.

For applications in the chemical or pharmaceutical industries involving aggressive media, a glass-filled compound is often a much safer and more reliable choice than a bronze-filled one.

Proper Gland and Piston Design

Even the best material will fail if not installed correctly. The piston groove must have the correct surface finish to prevent premature wear of the ring.

Furthermore, rings must be installed with minimal elongation to avoid permanent deformation and ensure proper sealing force against the cylinder wall.

Making the Right Choice for Your Application

The optimal material is the one that best balances the mechanical, thermal, and chemical demands of your specific system.

- If your primary focus is general-purpose, oil-free performance: Start with 15% Glass Filled PTFE for its balanced properties and excellent wear resistance.

- If your primary focus is high loads, high speeds, or managing heat: Choose 40% Bronze Filled PTFE for its superior thermal conductivity and compressive strength.

- If your primary focus is ultra-low friction or vacuum applications: Select 5% Moly Filled PTFE to achieve the lowest possible friction in dry-running conditions.

- If your primary focus is aggressive chemical compatibility: A glass-filled compound is a more reliable choice than bronze, which can corrode.

Ultimately, choosing the right material is a deliberate process of matching its enhanced properties to the unique challenges of your application.

Summary Table:

| Filler Material | Key Property Enhancement | Ideal Application |

|---|---|---|

| 15% Glass Filled PTFE | Excellent wear resistance & chemical compatibility | General-purpose, oil-free systems, chemical environments |

| 40% Bronze Filled PTFE | Superior thermal conductivity & compressive strength | High-speed, high-pressure, high-heat applications |

| 5% Molybdenum Disulfide (Moly) Filled PTFE | Ultra-low coefficient of friction | Vacuum pumps, dry-running, ultra-low friction systems |

Struggling to select the optimal PTFE piston ring material for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom piston rings, seals, and liners for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in material science and custom fabrication ensures you get a component engineered for your specific operating conditions—whether you need maximum wear resistance, superior thermal management, or the lowest possible friction.

We partner with you from prototype to high-volume production, prioritizing precision and performance to extend component life and enhance system reliability.

Contact our engineering team today for a consultation on your PTFE piston ring requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components