While prized for its exceptional chemical resistance, pure Polytetrafluoroethylene (PTFE) is not without its flaws as a gasket material. The most common defects are its tendency to creep (or "cold flow") under pressure and its low compressibility. Manufacturing processes can also introduce issues such as uneven density in molded gaskets or warping in those cut from sheets, all of which can compromise sealing performance.

The central challenge with standard PTFE gaskets is not a material defect, but rather its natural physical behavior. Successfully using PTFE requires acknowledging its tendency to deform and proactively managing it through material reinforcement and meticulous system design.

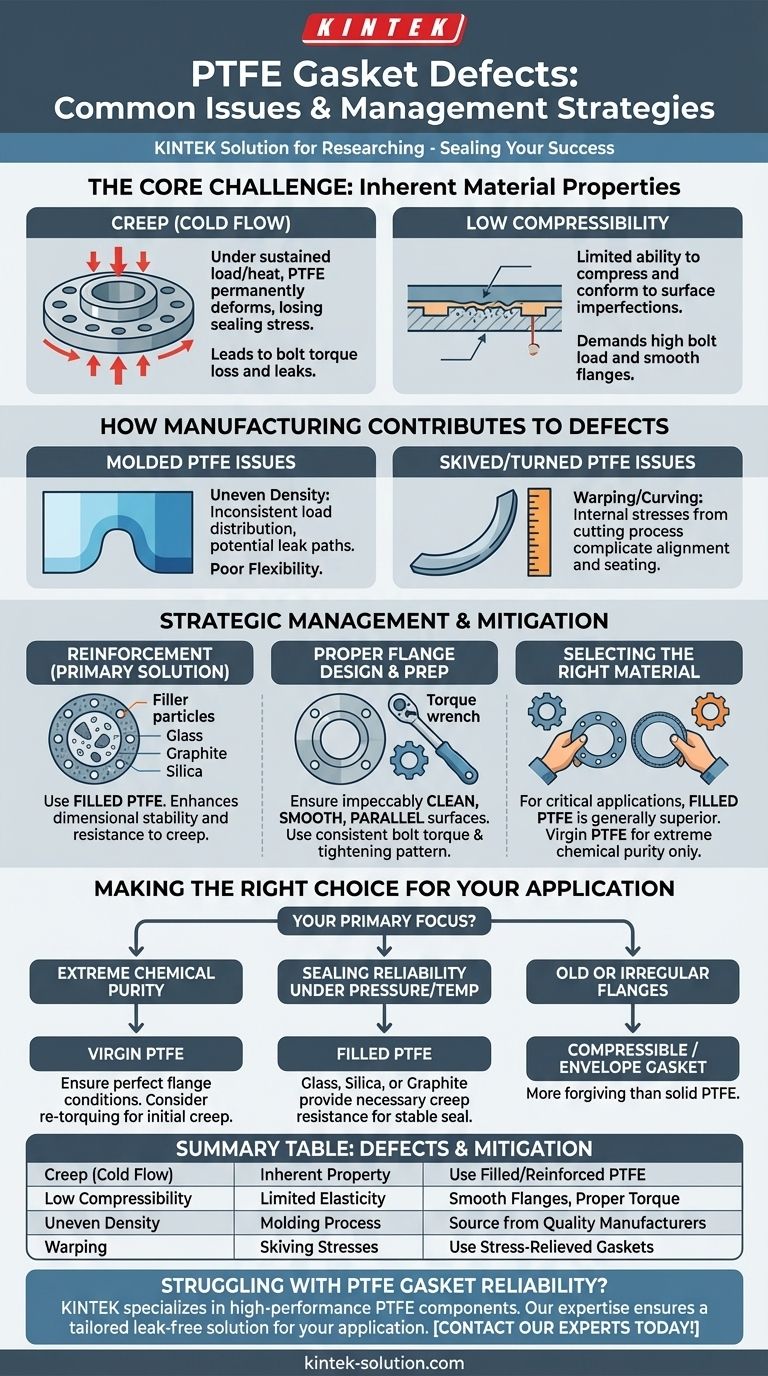

The Core Challenge: Inherent Material Properties

The most significant issues with PTFE gaskets stem directly from the fundamental properties of the polymer itself. Understanding these is the first step toward effective management.

What is Creep (Cold Flow)?

Under sustained compressive load, especially at elevated temperatures, PTFE material will slowly and permanently deform. It essentially "flows" away from the point of highest pressure.

This loss of material under the flange load reduces the sealing stress on the gasket. Over time, this can lead to a loss of bolt torque and, ultimately, a leak.

The Impact of Low Compressibility

Unlike more elastic materials, PTFE is not very "spongy." It has limited ability to compress and conform to surface imperfections.

This means it is less forgiving of flange irregularities. Achieving a reliable seal with PTFE demands a higher bolt load and exceptionally clean, smooth, and parallel flange faces.

How Manufacturing Contributes to Defects

The way a PTFE gasket is produced can introduce its own set of potential problems that affect installation and performance.

Issues with Molded PTFE

Gaskets molded directly from suspended PTFE resin can sometimes suffer from uneven density and poor flexibility.

An inconsistent density across the gasket surface means the compressive load is not distributed evenly, creating potential leak paths and points of premature failure.

Issues with Skived or Turned PTFE

Gaskets cut (or "skived") from large sheets or rods of PTFE generally have a more uniform density.

However, the manufacturing process can induce internal stresses in the material. This can cause the finished gasket to warp or curve, complicating proper alignment and seating during installation.

Strategic Management and Mitigation

Fortunately, these known weaknesses can be effectively managed through a combination of material science and proper engineering practices.

Reinforcement: The Primary Solution to Creep

The most effective way to combat cold flow is to use filled or reinforced PTFE.

Fillers such as glass fiber, silica, or graphite are mixed into the virgin PTFE matrix. These particles create an internal structure that significantly enhances dimensional stability and resistance to creep.

Proper Flange Design and Preparation

Because PTFE is not highly compressible, flange condition is critical. The surfaces must be impeccably clean, smooth, and free of scratches or tool marks.

Ensuring correct bolt torque and using a star or crisscross tightening pattern is also essential to apply a consistent, even pressure across the entire gasket surface.

Selecting the Right Material Grade

For critical, high-pressure, or high-temperature applications, a filled PTFE is almost always the superior choice over virgin PTFE due to its vastly improved mechanical stability. Virgin PTFE should be reserved for applications where its unparalleled chemical purity is the absolute priority.

Understanding the Trade-offs

Choosing the right PTFE gasket involves balancing performance needs. There is no single "best" option for every scenario.

Virgin PTFE vs. Filled PTFE

Virgin PTFE offers the highest level of chemical inertness and purity. However, it provides the lowest resistance to creep.

Filled PTFE gaskets offer dramatically better mechanical performance and sealability, but the filler material may slightly reduce the overall chemical compatibility. For example, glass-filled PTFE is not suitable for strong alkalis or hydrofluoric acid.

Cost vs. Reliability

Reinforced and specially engineered PTFE gaskets carry a higher upfront cost than simple virgin PTFE gaskets.

This additional cost should be viewed as an investment. It protects against the far greater expense and safety risk associated with a system leak, process contamination, or unscheduled downtime.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching the material's properties to the demands of your system.

- If your primary focus is extreme chemical purity or resistance: Virgin PTFE is the correct choice, but you must ensure perfect flange conditions and consider a re-torquing schedule to compensate for initial creep.

- If your primary focus is sealing reliability under pressure or temperature: A filled PTFE (such as glass, silica, or graphite-filled) provides the necessary creep resistance for a long-lasting, stable seal.

- If you are dealing with old or irregular flanges: A more compressible material or a composite gasket with a PTFE envelope may be a more forgiving and effective solution than solid PTFE.

By understanding these inherent material properties, you can engineer a sealing solution that leverages PTFE's strengths while successfully mitigating its weaknesses.

Summary Table:

| Defect Type | Primary Cause | Key Mitigation Strategy |

|---|---|---|

| Creep (Cold Flow) | Inherent PTFE property under load | Use filled/reinforced PTFE (e.g., glass, graphite) |

| Low Compressibility | Limited material elasticity | Ensure smooth, parallel flanges; proper bolt torque |

| Uneven Density | Inconsistent molding process | Source from quality-controlled manufacturers |

| Warping | Internal stresses from skiving/cutting | Use stress-relieved or molded gaskets |

Struggling with PTFE gasket reliability? KINTEK specializes in manufacturing high-performance PTFE components, including seals, liners, and custom gaskets for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a solution tailored to combat creep, cold flow, and other PTFE challenges. Let's engineer a leak-free sealing solution for your application—contact our experts today!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs