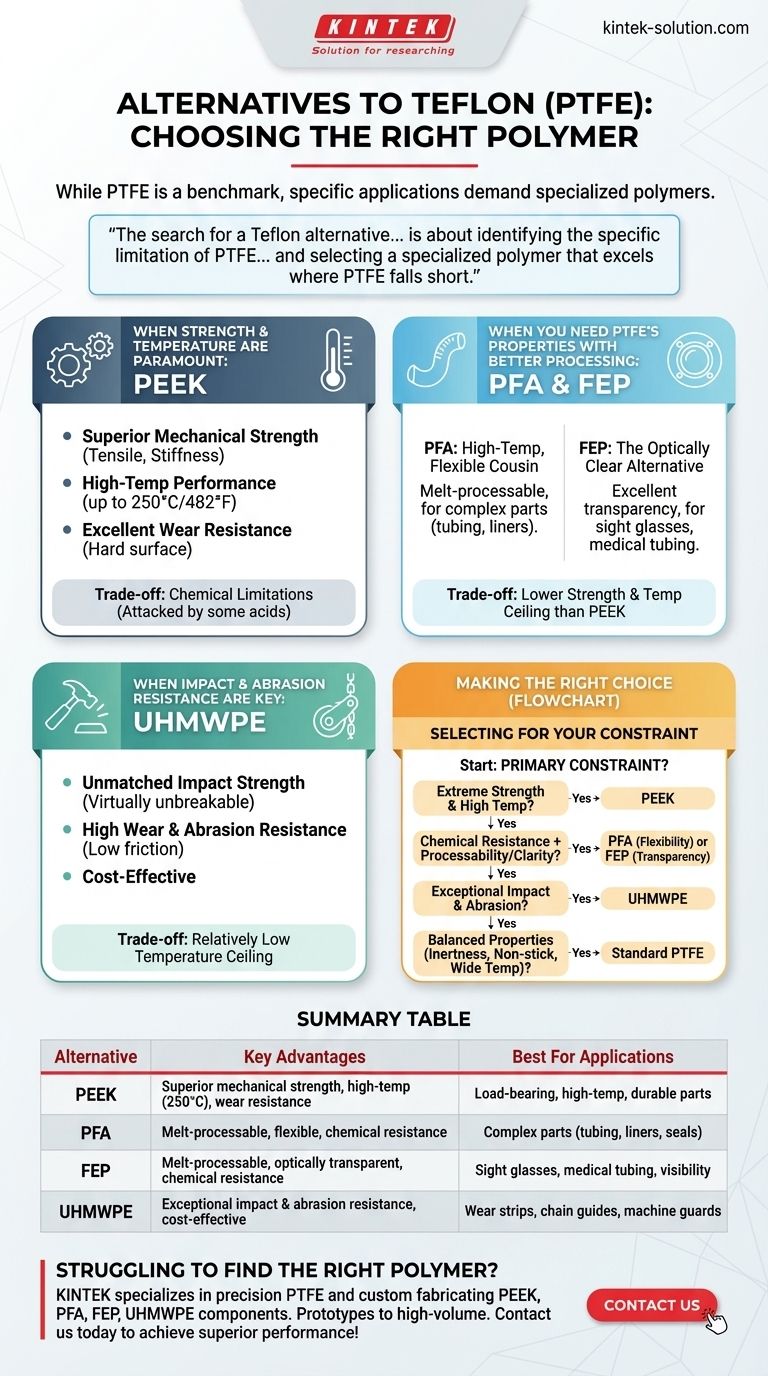

While Teflon (PTFE) is a benchmark material, several high-performance polymers offer superior properties in specific areas. The primary alternatives include PEEK for its mechanical and thermal strength, PFA and FEP for similar chemical resistance with better processability, and UHMWPE for its exceptional impact and wear resistance in mechanical applications.

The search for a Teflon alternative is not about finding a single "better" material. It is about identifying the specific limitation of PTFE in your application—be it strength, temperature, or transparency—and selecting a specialized polymer that excels where PTFE falls short.

When Strength and Temperature are Paramount: PEEK

Polyether Ether Ketone (PEEK) is the go-to alternative when the mechanical or thermal demands of an application exceed PTFE's capabilities.

Superior Mechanical Strength

PEEK offers significantly higher tensile strength and stiffness than PTFE. This makes it suitable for structural components that must bear heavy loads without deforming.

High-Temperature Performance

PEEK maintains its excellent mechanical properties at continuous service temperatures up to 250°C (482°F). This is a considerable advantage over PTFE's upper limit.

Excellent Wear Resistance

In applications involving friction and wear, PEEK demonstrates superior durability. Its hard surface resists abrasion far better than the relatively soft surface of PTFE.

When You Need PTFE's Properties with Better Processing: PFA & FEP

PFA and FEP are both fluoropolymers, sharing PTFE's renowned chemical inertness and non-stick properties. Their advantage lies in their melt-processability, which PTFE lacks.

PFA: The High-Temp, Flexible Cousin

Perfluoroalkoxy (PFA) has a temperature resistance nearly as high as PTFE but offers better flexibility and can be processed using conventional injection molding and extrusion. This makes it ideal for complex parts like tubing, liners, and seals.

FEP: The Optically Clear Alternative

Fluorinated Ethylene Propylene (FEP) is another melt-processable fluoropolymer that is notable for its excellent optical transparency. This makes it a preferred choice for sight glasses, medical tubing, and food processing applications where visibility is critical.

When Impact and Abrasion Resistance are Key: UHMWPE

For tough, mechanical applications at moderate temperatures, Ultra-High Molecular Weight Polyethylene (UHMWPE) is an outstanding and cost-effective option.

Unmatched Impact Strength

UHMWPE is one of the most durable thermoplastics available, with an impact strength that is virtually unbreakable. It is frequently used for wear strips, chain guides, and machine guards.

High Wear and Abrasion Resistance

This material has a very low coefficient of friction and exceptional resistance to abrasion. It often outwears steel in sliding applications, reducing noise and the need for lubrication.

Understanding the Trade-offs

No material is perfect. Choosing an alternative to PTFE requires acknowledging the compromises you are making.

PEEK's Chemical Limitations

While PEEK has good chemical resistance, it is not as universally inert as PTFE and its fluoropolymer relatives. It can be attacked by certain concentrated acids.

Fluoropolymer Strength

PFA and FEP, while easier to process, do not possess the same mechanical strength or high-temperature ceiling as PEEK. They are improvements on PTFE's processability, not its raw strength.

The Temperature Ceiling of UHMWPE

UHMWPE's primary limitation is its relatively low maximum service temperature, which is significantly lower than that of PEEK or any of the fluoropolymers.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary design constraint.

- If your primary focus is extreme mechanical strength and high-temperature stability: PEEK is the clear choice for load-bearing components in harsh environments.

- If your primary focus is chemical resistance but you need better melt-processability or optical clarity: Choose PFA for flexibility or FEP for transparency.

- If your primary focus is exceptional impact strength and abrasion resistance for mechanical parts: UHMWPE provides unmatched durability and value.

- If your primary focus is a balanced profile of chemical inertness, non-stick properties, and a wide temperature range: Standard PTFE often remains the most effective solution.

Ultimately, choosing the right polymer means aligning the material's distinct advantages with your most critical engineering goal.

Summary Table:

| Alternative | Key Advantages | Best For Applications |

|---|---|---|

| PEEK | Superior mechanical strength, high-temperature resistance (up to 250°C), excellent wear resistance | Load-bearing components, high-temperature environments, parts requiring durability |

| PFA | Melt-processable, flexible, chemical resistance similar to PTFE | Complex parts like tubing, liners, seals requiring easy fabrication |

| FEP | Melt-processable, optically transparent, chemical resistance | Sight glasses, medical tubing, food processing where visibility is key |

| UHMWPE | Exceptional impact strength, high abrasion resistance, cost-effective | Wear strips, chain guides, machine guards in mechanical applications |

Struggling to find the right polymer for your project? At KINTEK, we specialize in manufacturing precision PTFE components (seals, liners, labware) and custom fabricating parts from high-performance polymers like PEEK, PFA, FEP, and UHMWPE. Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures optimal material selection and precision production. Contact us today to discuss your requirements and let us help you achieve superior performance and durability in your applications!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- Why are PTFE balls particularly suitable for high-performance applications? Key Properties & Selection Guide

- What are the key chemical properties of PTFE balls? Unmatched Chemical & Thermal Stability

- What are the available grades of PTFE balls? Choose the Right Grade for Your Application

- What temperature range can Teflon (PTFE) balls withstand? -200°C to +260°C Performance Guide

- How do the chemical properties of PTFE balls influence their performance? Unmatched Durability in Harsh Environments