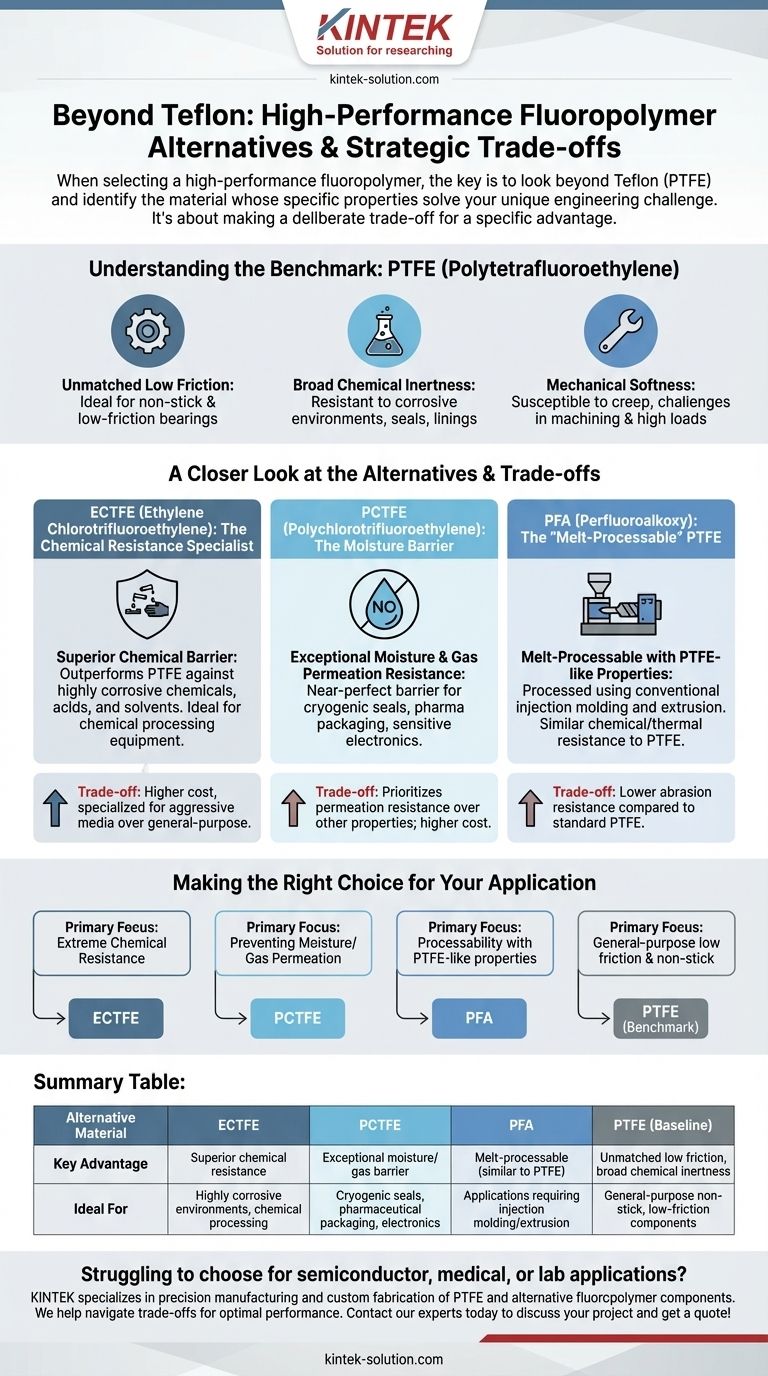

When selecting a high-performance fluoropolymer, the key is to look beyond Teflon (PTFE) and identify the material whose specific properties solve your unique engineering challenge. The most common alternatives are Ethylene Chlorotrifluoroethylene (ECTFE) for superior chemical resistance, Polychlorotrifluoroethylene (PCTFE) for exceptional water resistance, and Perfluoroalkoxy (PFA), which offers similar performance to PTFE but with different processing characteristics.

Choosing an alternative to Teflon is not about finding a universally "better" material. It's about making a deliberate trade-off to gain a specific advantage—such as enhanced chemical defense, moisture impermeability, or mechanical strength—that PTFE cannot provide for your application.

Understanding the Benchmark: Key Properties of PTFE

To choose the right alternative, we must first understand the baseline that standard Polytetrafluoroethylene (PTFE), or Teflon, establishes. It is an exceptional material, but its well-known strengths are balanced by inherent limitations.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any known solid. This is its defining characteristic, making it the go-to material for non-stick surfaces and low-friction bearings.

Broad Chemical Inertness

It is highly resistant to a vast range of chemicals, which is why it's used extensively in seals, gaskets, and linings for corrosive environments.

Mechanical Softness

A critical limitation of PTFE is its relative softness and susceptibility to creep (deformation under load). This can make it unsuitable for high-load structural components and presents challenges during machining, requiring sharp tools and careful temperature control to maintain tight tolerances.

A Closer Look at the Alternatives

Each alternative fluoropolymer modifies the foundational PTFE chemistry to enhance a specific property, creating a specialized tool for a specific job.

Ethylene Chlorotrifluoroethylene (ECTFE): The Chemical Resistance Specialist

ECTFE is engineered for environments where even PTFE falls short. It provides a superior barrier against a wide array of highly corrosive chemicals, acids, and solvents, making it a premier choice for chemical processing equipment.

Polychlorotrifluoroethylene (PCTFE): The Moisture Barrier

PCTFE's standout feature is its extremely low gas and water vapor permeability. It functions as a near-perfect barrier against moisture, making it invaluable for cryogenic seals, pharmaceutical packaging, and protecting sensitive electronics.

Perfluoroalkoxy (PFA): The "Melt-Processable" PTFE

PFA offers chemical and thermal resistance that is very similar to PTFE. Its primary advantage lies in its lower melt viscosity, which allows it to be processed using conventional injection molding and extrusion techniques, something not possible with standard PTFE. However, this comes at the cost of lower abrasion resistance.

Understanding the Trade-offs

Selecting a high-performance polymer is always an exercise in balancing competing factors. There is no single material that excels in every category.

Sacrificing One Property for Another

The decision to use an alternative is a strategic choice. By selecting ECTFE for its chemical resistance, you are prioritizing that property over others. Opting for PCTFE's moisture barrier means you have identified permeation as your primary failure risk.

Fabrication and Machinability

While PTFE's softness requires specific machining protocols like the use of exceptionally sharp tools, each alternative has its own distinct properties. Their relative hardness, thermal expansion rates, and stress characteristics will influence the ideal fabrication methods and costs.

The Cost Factor

Specialized materials designed for extreme performance naturally come at a premium. The cost of ECTFE, PCTFE, or PFA is often higher than standard PTFE, making it essential to justify the selection based on a critical performance requirement that only that material can meet.

Making the Right Choice for Your Application

Your final decision should be guided by the single most critical demand of your project.

- If your primary focus is extreme chemical resistance: ECTFE is likely the superior choice for handling the most aggressive media.

- If your primary focus is preventing moisture or gas permeation: PCTFE offers an unparalleled barrier against water vapor and other gases.

- If your primary focus is processability with PTFE-like properties: PFA provides similar chemical and thermal performance but allows for more versatile manufacturing methods like injection molding.

- If your primary focus is general-purpose low friction and non-stick surfaces: Standard PTFE often remains the most effective and well-rounded benchmark.

Ultimately, the best material is the one whose specific strengths align perfectly with the unique demands of your design.

Summary Table:

| Alternative Material | Key Advantage | Ideal For |

|---|---|---|

| ECTFE | Superior chemical resistance | Highly corrosive environments, chemical processing |

| PCTFE | Exceptional moisture/gas barrier | Cryogenic seals, pharmaceutical packaging, electronics |

| PFA | Melt-processable (similar to PTFE) | Applications requiring injection molding/extrusion |

| PTFE (Baseline) | Unmatched low friction, broad chemical inertness | General-purpose non-stick, low-friction components |

Struggling to choose the right high-performance fluoropolymer for your semiconductor, medical, or laboratory application? KINTEK specializes in the precision manufacturing and custom fabrication of PTFE and alternative fluoropolymer components like seals, liners, and labware. We help you navigate the trade-offs to select the optimal material, ensuring your design meets exacting performance requirements—from prototypes to high-volume production. Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How does PTFE perform when exposed to different types of water? Unmatched Chemical Resistance in Any Aqueous Environment

- What are the disadvantages of bronze bushings? Understanding the Trade-Offs for Heavy-Duty Applications

- What is the chemical composition of PTFE and why is it significant? Unlocking Its Unique Properties

- Is PTFE considered a metal or plastic? Understanding Its True Classification

- What are the main properties that make PTFE versatile across industries? Discover Its 5 Key Advantages

- What are some physical properties of PTFE? Master Its Unique Properties for Extreme Applications

- What is the tensile strength range of PTFE? Understanding Its Mechanical Limits for Your Design

- What are the properties of bronze-filled PTFE? A High-Performance Composite for Demanding Applications