At their core, PTFE bellows are flexible, convoluted connectors engineered from a high-performance fluoropolymer called polytetrafluoroethylene (PTFE), most famously known by the brand name Teflon. They are specifically designed to create a sealed connection between two points in a system while accommodating movement, vibration, and misalignment, particularly in environments where other materials would quickly fail.

The decision to use a PTFE bellow is not about finding a universal solution, but about solving a specific, challenging problem. Their value lies in an unparalleled resistance to chemicals and temperature, making them essential for critical applications where material failure is not an option.

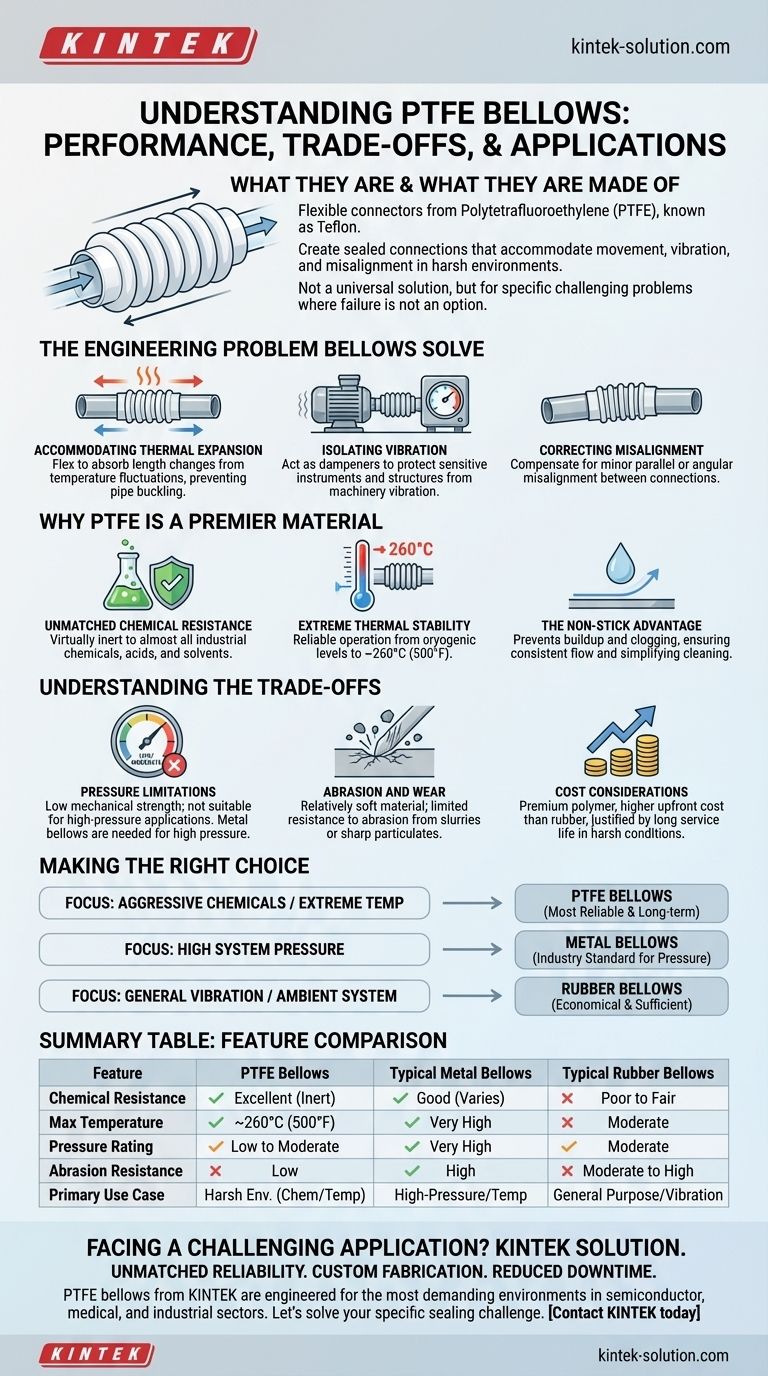

The Engineering Problem Bellows Solve

A bellows is fundamentally a flexible seal. Its purpose is to absorb or isolate movement and stress within a piping or ducting system, preventing that stress from damaging more rigid or sensitive components.

Accommodating Thermal Expansion

Piping systems expand and contract as temperatures fluctuate. A bellows flexes to absorb this change in length, preventing pipe buckling or damage to equipment nozzles.

Isolating Vibration

Pumps, motors, and other machinery introduce vibration into a system. A bellows acts as a dampener, isolating this vibration and protecting sensitive instruments or adjacent structures.

Correcting Misalignment

Perfect pipe alignment is often difficult or impossible to achieve during installation. A flexible bellows can compensate for minor parallel or angular misalignment between two connection points.

Why PTFE is a Premier Material for Bellows

While bellows can be made from metal, rubber, or composites, PTFE is chosen when the operational environment is exceptionally demanding. Its molecular structure—a chain of carbon atoms completely sheathed by fluorine atoms—gives it a unique combination of properties.

Unmatched Chemical Resistance

PTFE is virtually inert and non-reactive to almost all industrial chemicals and corrosive media. This makes it the default choice for systems handling acids, solvents, or other aggressive substances that would degrade rubber or even specialized metals.

Extreme Thermal Stability

PTFE bellows can operate reliably across a vast temperature range, from cryogenic levels up to approximately 260°C (500°F). This stability ensures they maintain their integrity and flexibility in applications involving extreme heat or cold.

The Non-Stick Advantage

The surface of PTFE is famously non-adhesive. This property prevents process media from building up, caking, or clogging the bellows, which ensures consistent flow and simplifies cleaning and maintenance, a critical factor in pharmaceutical and semiconductor manufacturing.

Understanding the Trade-offs

No material is perfect. The unique strengths of PTFE come with clear limitations that are critical to understand before specifying it for an application.

Pressure Limitations

The primary weakness of standard PTFE bellows is their relatively low mechanical strength. They are not suitable for high-pressure applications. For such systems, metal or specially reinforced bellows are the appropriate choice.

Abrasion and Wear

While chemically durable, PTFE is a relatively soft material with limited resistance to abrasion. It is not recommended for conveying abrasive slurries or materials with sharp particulates, as these can quickly wear down the convoluted surfaces.

Cost Considerations

PTFE is a premium, high-performance polymer. As a result, bellows made from it are typically more expensive than those made from standard EPDM rubber or other common elastomers. The higher upfront cost is justified by its long service life and reliability in harsh environments.

Making the Right Choice for Your System

Selecting the correct bellows material requires a clear understanding of your system's operational demands. The choice is a direct trade-off between performance requirements and cost.

- If your primary focus is handling aggressive chemicals or extreme temperatures: PTFE is almost certainly the correct and most reliable choice for long-term performance.

- If your primary focus is managing high system pressure: A metal bellows is the industry standard and the only safe option for these conditions.

- If your primary focus is general-purpose vibration damping in a non-corrosive, ambient temperature system: A more economical rubber or elastomeric bellow will likely provide sufficient performance at a lower cost.

Ultimately, specifying a PTFE bellow is an engineering decision to prioritize chemical and thermal resilience above all other factors.

Summary Table:

| Feature | PTFE Bellows | Typical Metal Bellows | Typical Rubber Bellows |

|---|---|---|---|

| Chemical Resistance | Excellent (Virtually Inert) | Good (Varies by alloy) | Poor to Fair |

| Max Temperature | ~260°C (500°F) | Very High | Moderate |

| Pressure Rating | Low to Moderate | Very High | Moderate |

| Abrasion Resistance | Low | High | Moderate to High |

| Primary Use Case | Harsh Chemical/Temperature Environments | High-Pressure/High-Temperature Systems | General Purpose/Vibration Damping |

Facing a challenging chemical, thermal, or purity application?

PTFE bellows from KINTEK are engineered to provide a reliable, long-lasting seal in the most demanding environments. We specialize in manufacturing high-precision PTFE components, including custom bellows, for the semiconductor, medical, laboratory, and industrial sectors.

Our expertise ensures your system benefits from:

- Unmatched Reliability: Superior material performance in corrosive and extreme temperature conditions.

- Custom Fabrication: Solutions tailored from prototype to high-volume production to meet your exact specifications.

- Reduced Downtime: Non-stick properties prevent buildup and simplify maintenance.

Let's solve your specific sealing challenge. Contact KINTEK today to discuss your application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- How is PTFE used in industrial processes? Maximize Safety and Efficiency