At its core, an expanded PTFE (ePTFE) gasket is a high-performance sealing material made from 100% virgin Polytetrafluoroethylene (PTFE). It is manufactured through a unique mechanical stretching process that transforms the normally rigid PTFE into a soft, flexible, and highly compressible sheet. This process creates a microporous structure of interconnected fibers, giving the material its superior sealing ability.

The critical insight is that the expansion process fundamentally changes PTFE's physical properties. It turns a rigid, non-elastic plastic into a conformable material that excels at creating tight, durable seals, especially on irregular or imperfect surfaces where standard gaskets might fail.

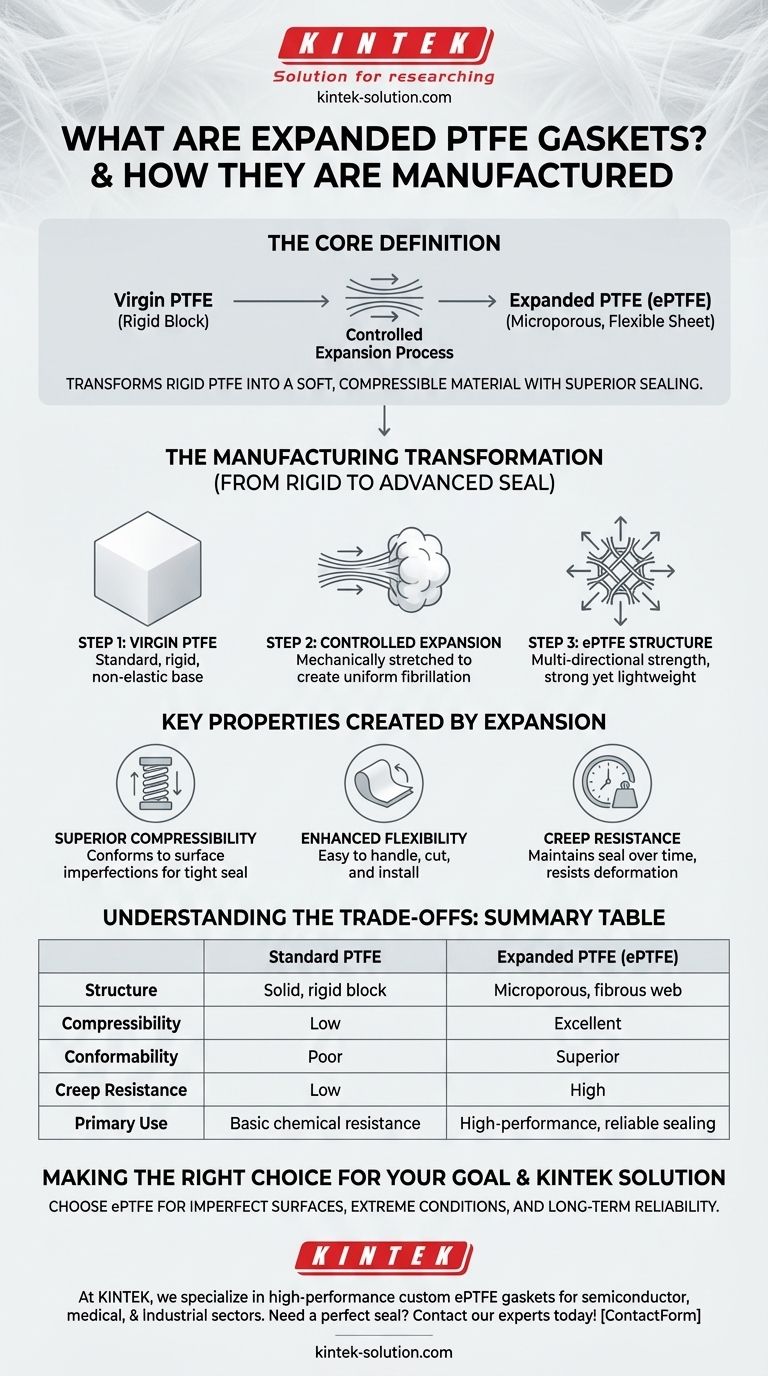

The Transformation: From Rigid Plastic to Advanced Seal

Understanding how ePTFE is made reveals why it performs so well. The process is one of physical transformation, not chemical alteration.

The Starting Point: 100% Virgin PTFE

The process begins with pure, unadulterated PTFE. This base material is renowned for its exceptional chemical inertness and high-temperature resistance.

However, in its standard, solid form, PTFE lacks elasticity. It is a rigid material that does not easily return to its original shape after being compressed.

The Key Process: Controlled Mechanical Expansion

To create ePTFE, the virgin PTFE is mechanically stretched or "expanded" in a controlled manner. This pulling action creates a uniform, highly fibrillated microstructure.

Think of it like pulling apart a cotton ball. The solid mass transforms into a web of interconnected fibers. This fibrous, microporous structure is the defining characteristic of ePTFE.

The Final Structure: Multi-Directional Strength

The resulting material has equal tensile strength in all directions. Unlike materials with a structural grain that can be a point of weakness, ePTFE's web of fibers resists forces uniformly.

This multi-directional fiber structure makes it incredibly strong yet lightweight and highly adaptable to sealing surfaces.

Key Properties Created by Expansion

The manufacturing process directly imparts the unique properties that make ePTFE an elite sealing solution.

Superior Compressibility

The microporous structure allows the material to compress easily under load. This enables it to conform perfectly to surface imperfections like scratches or warping on flanges, ensuring an extremely tight seal.

Enhanced Flexibility

Unlike its rigid parent material, ePTFE is soft and pliable. This makes it much easier to handle, cut, and install, especially in complex or tight spaces.

Creep Resistance

While standard PTFE can deform permanently under pressure (a phenomenon known as "creep"), the fibrous structure of ePTFE provides excellent resistance to this, maintaining a reliable seal over time despite pressure and temperature fluctuations.

Understanding the Trade-offs: Expanded vs. Other PTFE Forms

While ePTFE is a superior sealing material, it's important to understand how it compares to other forms of PTFE.

The Limitation of Standard PTFE Gaskets

Standard, non-expanded PTFE gaskets are simply cut or molded from a solid block of the material. Their rigidity makes them unsuitable for sealing anything but perfectly flat, smooth surfaces. They are less forgiving and more prone to leaking on real-world equipment.

The Role of Filled PTFE

Another variant is filled PTFE, where substances like glass fibers or graphite are mixed into the base PTFE polymer. This is done to enhance specific mechanical properties like wear resistance or thermal conductivity.

However, this solves a different problem. Filled PTFE is about improving mechanical durability, whereas ePTFE is engineered specifically for superior sealing performance and conformability.

Making the Right Choice for Your Goal

Selecting the correct gasket material depends entirely on the demands of your application.

- If your primary focus is sealing irregular, pitted, or warped flanges: Choose expanded PTFE. Its exceptional compressibility is precisely what you need to create a reliable seal on imperfect surfaces.

- If your primary focus is extreme chemical resistance with fluctuating temperatures: Choose expanded PTFE. It retains the chemical inertness of virgin PTFE while adding the resilience needed to maintain a seal under dynamic conditions.

- If your primary focus is wear resistance in a dynamic part, not a static seal: A filled PTFE might be the more appropriate choice to handle friction and abrasion.

Ultimately, understanding the expansion process makes it clear why ePTFE stands apart as a uniquely effective and versatile sealing solution.

Summary Table:

| Property | Standard PTFE | Expanded PTFE (ePTFE) |

|---|---|---|

| Structure | Solid, rigid block | Microporous, fibrous web |

| Compressibility | Low | Excellent |

| Conformability | Poor (needs flat surfaces) | Superior (seals imperfect flanges) |

| Creep Resistance | Low | High |

| Primary Use | Basic chemical resistance | High-performance, reliable sealing |

Need a gasket that seals perfectly, even on imperfect surfaces?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom expanded PTFE gaskets. Our precision production process ensures your seals offer superior compressibility, flexibility, and long-term reliability—exactly what the semiconductor, medical, laboratory, and industrial sectors require.

Whether you need prototypes or high-volume orders, we deliver custom solutions that meet your exact specifications. Let's discuss your application and find the perfect sealing solution. Contact our experts today!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs