To prevent failure when using PTFE gaskets, the most common mistakes are selecting the wrong size or type for the application's pressure and chemical environment, and improper handling that leads to contamination or surface damage. These errors compromise the integrity of the seal, leading directly to leaks and system downtime.

The key to successfully using PTFE gaskets is recognizing their unique material properties. While they offer superior chemical and thermal resistance, their softness and tendency to deform under pressure mean that proper selection and careful installation are not just best practices—they are absolute requirements for a reliable seal.

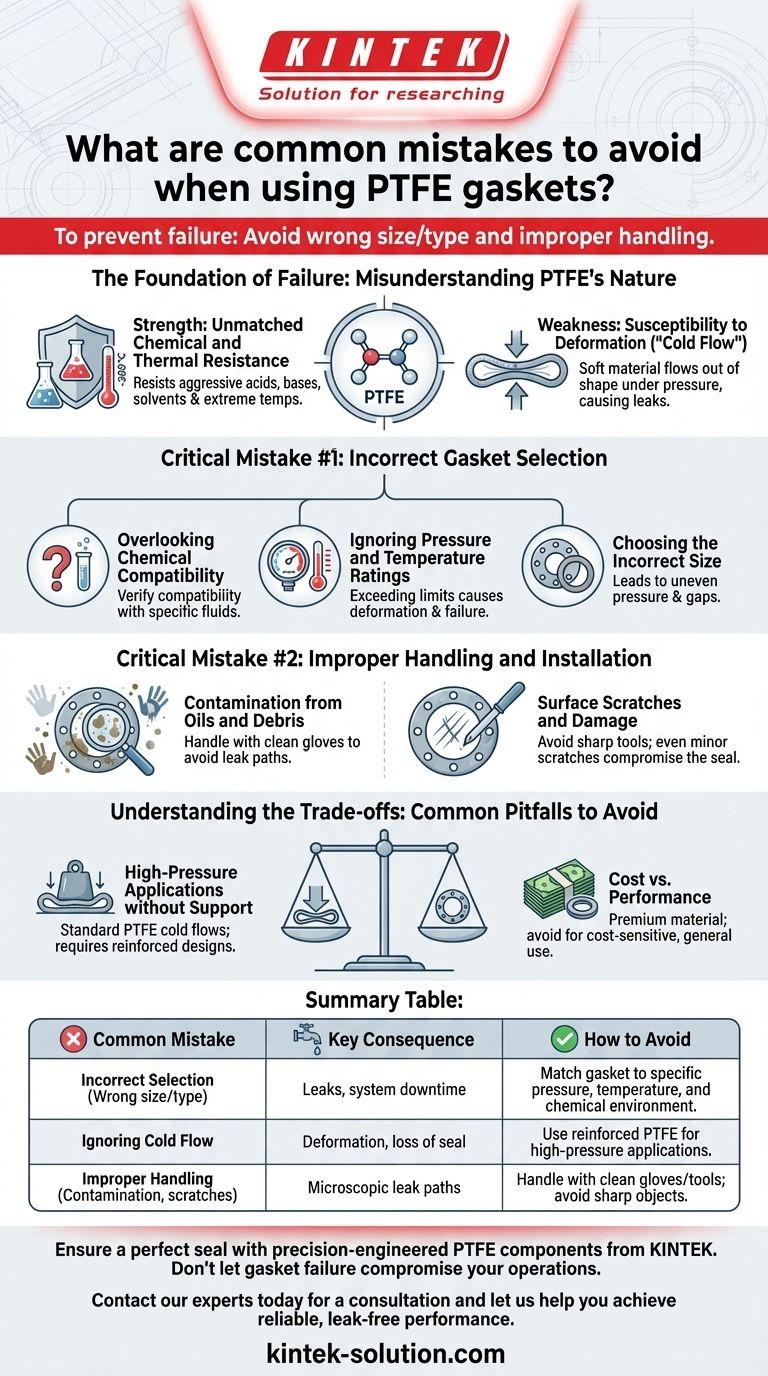

The Foundation of Failure: Misunderstanding PTFE's Nature

Most errors stem from a failure to appreciate the fundamental characteristics of Polytetrafluoroethylene (PTFE). It is not a simple drop-in replacement for traditional rubber or fiber gaskets.

Strength: Unmatched Chemical and Thermal Resistance

PTFE is chosen for its remarkable ability to withstand aggressive acids, bases, and solvents. It also performs reliably across an extremely wide temperature range, from -200°C to +260°C (-328°F to +500°F).

Weakness: Susceptibility to Deformation ("Cold Flow")

The most critical disadvantage of PTFE is its softness. When subjected to pressure, especially over time, it can deform or "flow" out of shape. This tendency, known as cold flow, can reduce sealing effectiveness and is a primary cause of leaks in poorly designed applications.

Critical Mistake #1: Incorrect Gasket Selection

Choosing the right gasket is the first and most important step. A mistake here guarantees problems down the line.

Overlooking Chemical Compatibility

While PTFE is resistant to most chemicals, you must always verify its compatibility with the specific fluids in your system. Assuming compatibility without confirmation is a needless risk.

Ignoring Pressure and Temperature Ratings

Every gasket has defined operational limits. Using a standard PTFE gasket in an application that exceeds its pressure rating will almost certainly cause it to deform and fail. This is especially true in high-pressure systems where specialized or reinforced PTFE designs are necessary.

Choosing the Incorrect Size

An improperly sized gasket—whether too large or too small for the flange—will not seat correctly. This creates uneven pressure distribution, leading to gaps and inevitable leaks.

Critical Mistake #2: Improper Handling and Installation

Even the perfect gasket will fail if it is damaged before or during installation. PTFE's soft surface requires careful attention.

Contamination from Oils and Debris

Always handle PTFE gaskets with clean gloves or tools. Oils from your hands, dust, or other particles can get trapped between the gasket and the flange, creating a microscopic leak path that can worsen over time.

Surface Scratches and Damage

Never use sharp tools or place the gasket on rough surfaces. Even minor scratches on the sealing face can compromise its ability to create a perfect, leak-free seal. These imperfections become weak points under pressure.

Understanding the Trade-offs: Common Pitfalls to Avoid

PTFE is an excellent material, but it is not universally applicable. Knowing its limitations is key to avoiding misapplication.

High-Pressure Applications without Support

Standard, unmodified PTFE gaskets are generally unsuitable for very high-pressure applications due to their tendency to cold flow. In these scenarios, filled or reinforced PTFE gaskets are required to provide the necessary mechanical strength and resist deformation.

Scenarios with High Mechanical Loads

Because of its lower mechanical strength compared to other materials, PTFE can be crushed or damaged under heavy mechanical loads. It is not ideal for applications where the gasket must also serve a structural role.

Cost vs. Performance

PTFE is a premium material and is more expensive than many traditional rubber or fiber gaskets. Using it where a less expensive material would suffice is an unnecessary cost. Its benefits are most realized in demanding chemical or temperature environments.

Making the Right Choice for Your Application

To avoid these common mistakes, your selection process must be deliberate and matched to your operational needs.

- If your primary focus is sealing aggressive chemicals or extreme temperatures: PTFE is likely the correct choice, but you must meticulously verify pressure ratings and ensure pristine handling.

- If your primary focus is a high-pressure system: Standard PTFE is the wrong choice. You must specify a filled, reinforced, or specially designed gasket engineered to resist cold flow.

- If your primary focus is a general-purpose, cost-sensitive application: A traditional rubber or composite gasket may offer better value without the handling sensitivities of PTFE.

Ultimately, a reliable seal depends on matching the unique properties of the gasket material to the precise demands of your system.

Summary Table:

| Common Mistake | Key Consequence | How to Avoid |

|---|---|---|

| Incorrect Selection (Wrong size/type) | Leaks, system downtime | Match gasket to specific pressure, temperature, and chemical environment. |

| Ignoring Cold Flow | Deformation, loss of seal | Use reinforced PTFE for high-pressure applications. |

| Improper Handling (Contamination, scratches) | Microscopic leak paths | Handle with clean gloves/tools; avoid sharp objects. |

Ensure a perfect seal with precision-engineered PTFE components from KINTEK.

Don't let gasket failure compromise your operations. Our expertise in custom PTFE fabrication for the semiconductor, medical, laboratory, and industrial sectors ensures you get the right component for your exact pressure, chemical, and temperature requirements—from prototypes to high-volume orders.

Contact our experts today for a consultation and let us help you achieve reliable, leak-free performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE shaft seals? Superior Performance in Extreme Conditions

- What makes PTFE gaskets suitable for the food industry? Ensure Purity and Compliance

- What types of applications are PTFE gaskets suitable for? The Ultimate Guide for Extreme Environments

- Why are PTFE-lined valves considered low maintenance? Achieve Maximum Uptime & Lower Costs

- What is expanded PTFE (ePTFE) and how is it produced? Unlock Superior Sealing and Insulation

- What are the symptoms of temperature-induced seal failure? Diagnose Leaks and Prevent Downtime

- What is the maximum pressure that PTFE piston seals can handle? Understand the Full System of Limits

- What are the main advantages of PTFE lip seals? Superior Sealing for Extreme Conditions