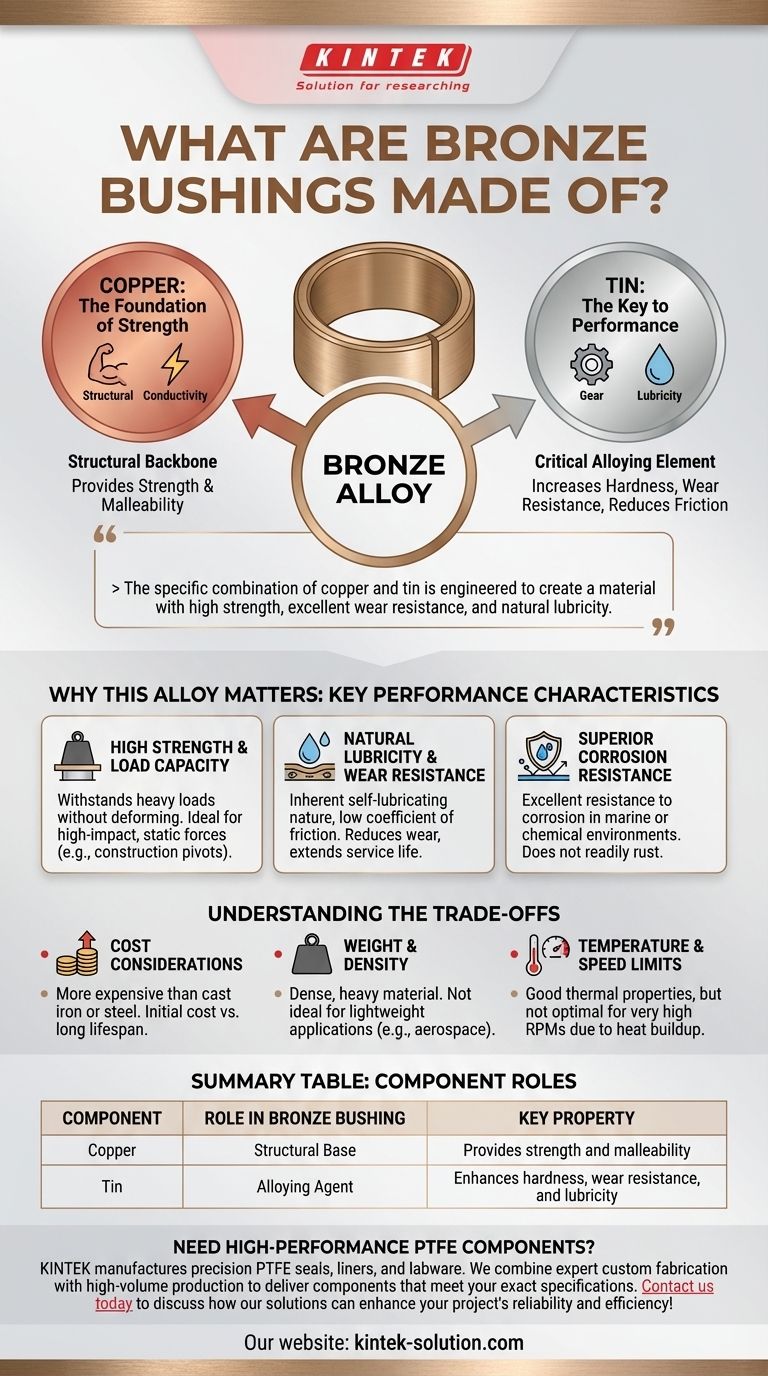

At their core, bronze bushings are a simple yet powerful alloy. They are made from a mixture of copper, which serves as the primary base metal, and tin as the main alloying agent.

The specific combination of copper and tin is not arbitrary; it is engineered to create a material with high strength, excellent wear resistance, and natural lubricity, making it superior to its constituent metals for demanding mechanical applications.

The Core Components of Bronze and Their Roles

Understanding why bronze is so effective requires looking at how its two main ingredients contribute to its final properties. The blend is what gives the material its distinct advantages.

Copper: The Foundation of Strength

Copper forms the structural backbone of the alloy. On its own, copper is a relatively soft, ductile metal known for its excellent electrical and thermal conductivity.

Its primary role in the bronze alloy is to provide fundamental strength and malleability, creating a robust base for the bushing.

Tin: The Key to Performance

Tin is the critical alloying element that transforms copper into bronze. The addition of tin significantly increases the hardness and strength of the material.

Most importantly, tin improves the alloy's wear resistance and reduces the coefficient of friction, giving bronze its characteristic ability to withstand sliding contact with less wear and tear.

Why This Alloy Matters: Key Performance Characteristics

The specific properties derived from the copper-tin alloy directly address common engineering challenges, making bronze the material of choice in many situations.

High Strength and Load Capacity

Bronze bushings are known for their ability to withstand heavy loads without deforming. This high compressive strength makes them ideal for applications involving high-impact or static forces, such as in construction equipment pivots or industrial machinery.

Natural Lubricity and Wear Resistance

One of the most valuable properties of bronze is its inherent self-lubricating nature. The material has a low coefficient of friction, which allows it to operate smoothly against other metal surfaces, often with minimal external lubrication.

This characteristic dramatically reduces wear on both the bushing and the shaft it supports, leading to longer service life and lower maintenance requirements.

Superior Corrosion Resistance

The copper content in bronze provides excellent resistance to corrosion, particularly in marine or chemically aggressive environments. Unlike iron or steel, bronze does not readily rust, making it a reliable choice for pumps, valves, and underwater applications.

Understanding the Trade-offs

While highly effective, bronze is not the universal solution for every application. Acknowledging its limitations is key to making an informed decision.

Cost Considerations

The primary components of bronze, especially copper, make it a more expensive material compared to common alternatives like cast iron, steel, or many engineering plastics. The initial cost must be weighed against its longer lifespan and lower maintenance needs.

Weight and Density

Bronze is a dense, heavy material. In applications where weight is a critical design factor, such as in aerospace or lightweight robotics, aluminum or polymer-based bushings may be a more suitable choice.

Temperature and Speed Limits

While bronze has good thermal properties, it may not be the optimal choice for extremely high-speed rotational applications. At very high RPMs, heat buildup can become a significant issue, potentially favoring ball or roller bearings designed for such conditions.

Making the Right Choice for Your Application

Selecting the correct bushing material depends entirely on the demands of your specific project.

- If your primary focus is high loads and durability: Bronze's compressive strength and wear resistance make it an ideal choice for low-speed, high-impact machinery.

- If your primary focus is corrosion resistance: For marine, chemical, or outdoor applications, the inherent rust-proof nature of bronze is a decisive advantage.

- If your primary focus is low maintenance: The self-lubricating properties of bronze are perfect for hard-to-reach locations where regular servicing is impractical.

Understanding that bronze is an engineered alloy of copper and tin allows you to confidently specify it for applications where strength, longevity, and reliability are paramount.

Summary Table:

| Component | Role in Bronze Bushing | Key Property |

|---|---|---|

| Copper | Structural Base | Provides strength and malleability |

| Tin | Alloying Agent | Enhances hardness, wear resistance, and lubricity |

Need high-performance PTFE components for your specialized applications? KINTEK manufactures precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We combine expert custom fabrication with high-volume production capabilities to deliver components that meet your exact specifications. Contact us today to discuss how our solutions can enhance your project's reliability and efficiency!

Visual Guide

Related Products

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What is the flexural strength of PTFE? Discover Its Unique Flexibility & Performance

- What is the chemical composition of Teflon? The Science Behind Its Non-Stick Properties

- What are some alternatives to Teflon/PTFE? Explore High-Performance Polymers for Your Application

- How does Teflon compare to rubber in terms of performance? A Guide to Selecting the Right Material for Extreme Conditions

- What is the difference between virgin and modified PTFE? Choose the Right Material for Your Application

- What are the benefits of using PTFE? Achieve Unmatched Performance in Extreme Environments

- What family of substances does PTFE belong to? Understanding PFAS & Fluoropolymer Safety

- What industries commonly use Teflon material? Unlocking Versatility Across Sectors