The primary advantages of PTFE packing stem from its unique molecular structure, which makes it exceptionally stable and non-reactive. This results in a material with outstanding chemical resistance, an extremely low coefficient of friction, and stability across a wide range of temperatures, making it a highly versatile sealing solution for demanding industrial environments.

The true advantage of PTFE packing lies not in any single property, but in how its chemical inertness, low friction, and thermal stability combine to solve critical sealing challenges—protecting equipment, ensuring product purity, and reducing operational costs.

The Core Advantages Explained

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer. The strength of its carbon-fluorine bonds is the source of its most valued characteristics.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials used in industry. It is virtually unaffected by aggressive acids, solvents, bases, and oxidizers.

This makes it an ideal choice for equipment handling corrosive media such as concentrated sulfuric acid or nitric acid. The only common exceptions are molten alkali metals and highly reactive fluorinating agents.

Extremely Low Friction

PTFE possesses the lowest coefficient of friction of any known solid material. This non-stick quality delivers two significant operational benefits.

First, it minimizes wear and tear on rotating equipment like pump shafts and valve stems, extending the service life of expensive components. Second, the low friction reduces the energy required to operate the equipment, leading to lower power consumption.

Wide Temperature Stability

PTFE packing performs reliably across an exceptionally broad temperature spectrum. It remains effective in cryogenic conditions and can handle continuous operating temperatures up to 260°C (500°F).

This thermal stability allows it to be used in applications ranging from liquid natural gas processing to high-temperature steam systems without degrading.

Purity for Sensitive Applications

Because PTFE is inert and does not shed contaminants or color, it can be manufactured to meet strict regulatory standards, including those from the FDA.

This makes it a default choice for the food, beverage, and pharmaceutical industries, where preventing product contamination is non-negotiable. Its non-toxic nature ensures seal integrity without compromising product safety.

Where These Advantages Matter Most

The combination of these properties makes PTFE a problem-solver across many sectors.

Chemical and Petrochemical Processing

In reactors, mixers, and pumps handling corrosive substances, PTFE packing prevents leaks and protects equipment from chemical attack.

Food, Beverage, and Pharmaceuticals

For any equipment involved in processing consumables, FDA-compliant PTFE provides a sterile, non-toxic, and non-reactive sealing surface.

Pumps, Valves, and Rotating Equipment

In general industrial use, PTFE's low-friction nature is prized for reducing maintenance downtime and energy costs associated with pumps and valves.

Aerospace and Marine Environments

PTFE is used where equipment must withstand extreme temperature fluctuations and corrosive environments, such as saltwater exposure.

Understanding the Trade-offs and Selection Criteria

While highly capable, PTFE is not a universal solution. Its performance is contingent on matching the material to the specific operational demands.

Evaluating Pressure and Mechanical Stress

Pure PTFE is a relatively soft material. In very high-pressure applications or situations with significant mechanical stress, it may be prone to extrusion or "cold flow." In these cases, PTFE is often braided with reinforcing materials like carbon or aramid fibers to improve its strength.

The Importance of Temperature Limits

Although the temperature range is wide, it is finite. Exceeding its upper limit of around 260°C (500°F) will cause the material to degrade and release fumes, leading to seal failure.

Specific Chemical Exclusions

Always confirm that the process media does not include substances known to react with PTFE, primarily molten alkali metals. While rare, this is a critical check for specific high-temperature chemical processes.

Making the Right Choice for Your Application

Selecting the correct packing requires aligning the material's strengths with your primary goal.

- If your primary focus is handling aggressive chemicals: PTFE is a leading choice due to its near-total inertness.

- If your primary focus is protecting equipment and saving energy: The extremely low friction of PTFE packing minimizes shaft wear and reduces power consumption.

- If your primary focus is product purity (food, pharma): Ensure you select an FDA-compliant grade of PTFE packing to prevent contamination.

- If you are operating at extreme temperatures: Verify your specific operational range falls within PTFE's stable limits, from cryogenic up to approximately 260°C (500°F).

By understanding these core strengths and operational limits, you can confidently specify PTFE packing where it will deliver maximum value and reliability.

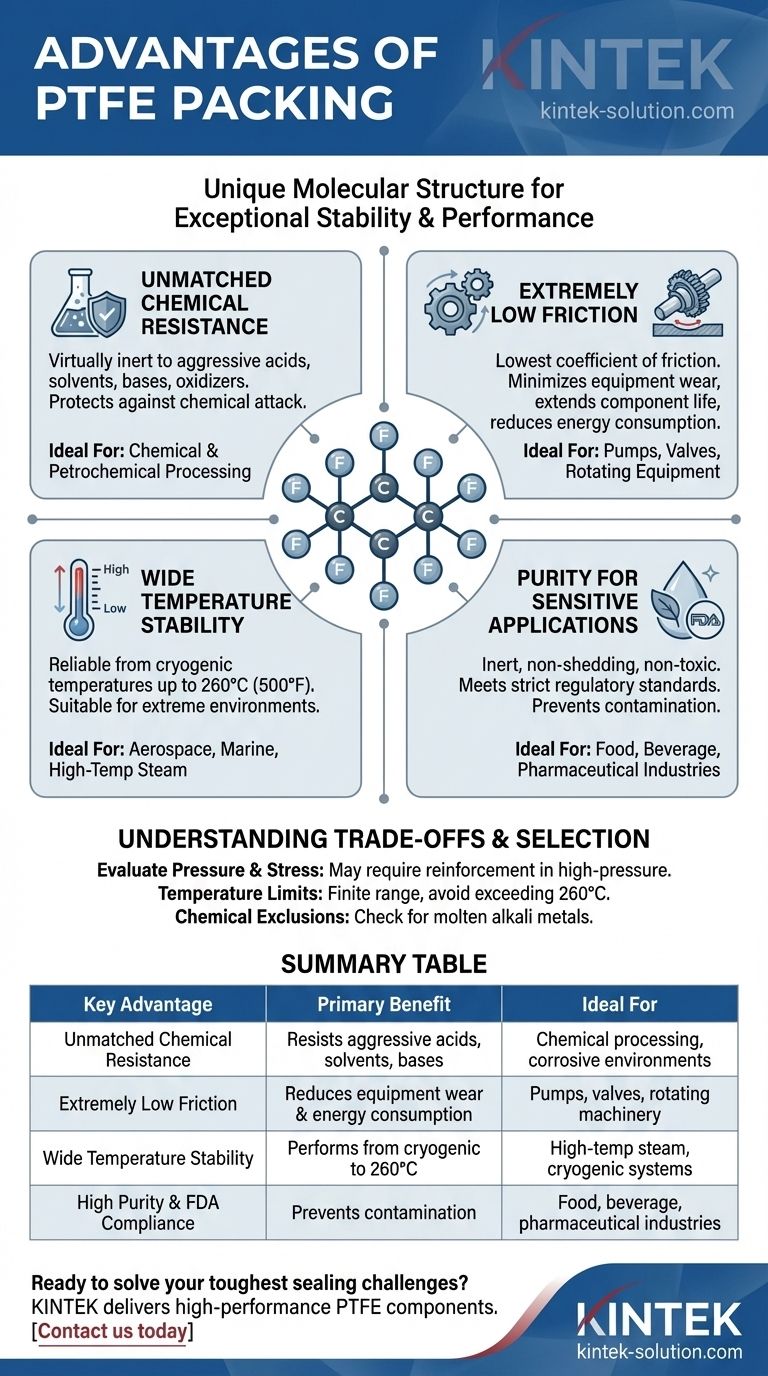

Summary Table:

| Key Advantage | Primary Benefit | Ideal For |

|---|---|---|

| Unmatched Chemical Resistance | Resists aggressive acids, solvents, and bases | Chemical processing, corrosive environments |

| Extremely Low Friction | Reduces equipment wear and energy consumption | Pumps, valves, rotating machinery |

| Wide Temperature Stability | Performs from cryogenic to 260°C (500°F) | High-temperature steam, cryogenic systems |

| High Purity & FDA Compliance | Prevents contamination in sensitive products | Food, beverage, pharmaceutical industries |

Ready to solve your toughest sealing challenges?

PTFE packing from KINTEK delivers the chemical resistance, low friction, and thermal stability your application demands. We specialize in manufacturing high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

Whether you need a prototype or high-volume production, our precision manufacturing ensures reliability and purity.

Contact us today to discuss your specific requirements and let our experts help you select the ideal PTFE solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance