At its core, Polytetrafluoroethylene (PTFE) offers three primary advantages as a valve seat material: an extremely low coefficient of friction, near-universal chemical resistance, and a very wide operating temperature range. These properties work together to create a reliable, low-maintenance seal that requires minimal energy to operate.

PTFE is the material of choice for demanding applications where smooth operation and resistance to corrosive media are critical. However, its effectiveness is defined by understanding its mechanical limitations, particularly its relatively low strength compared to harder materials.

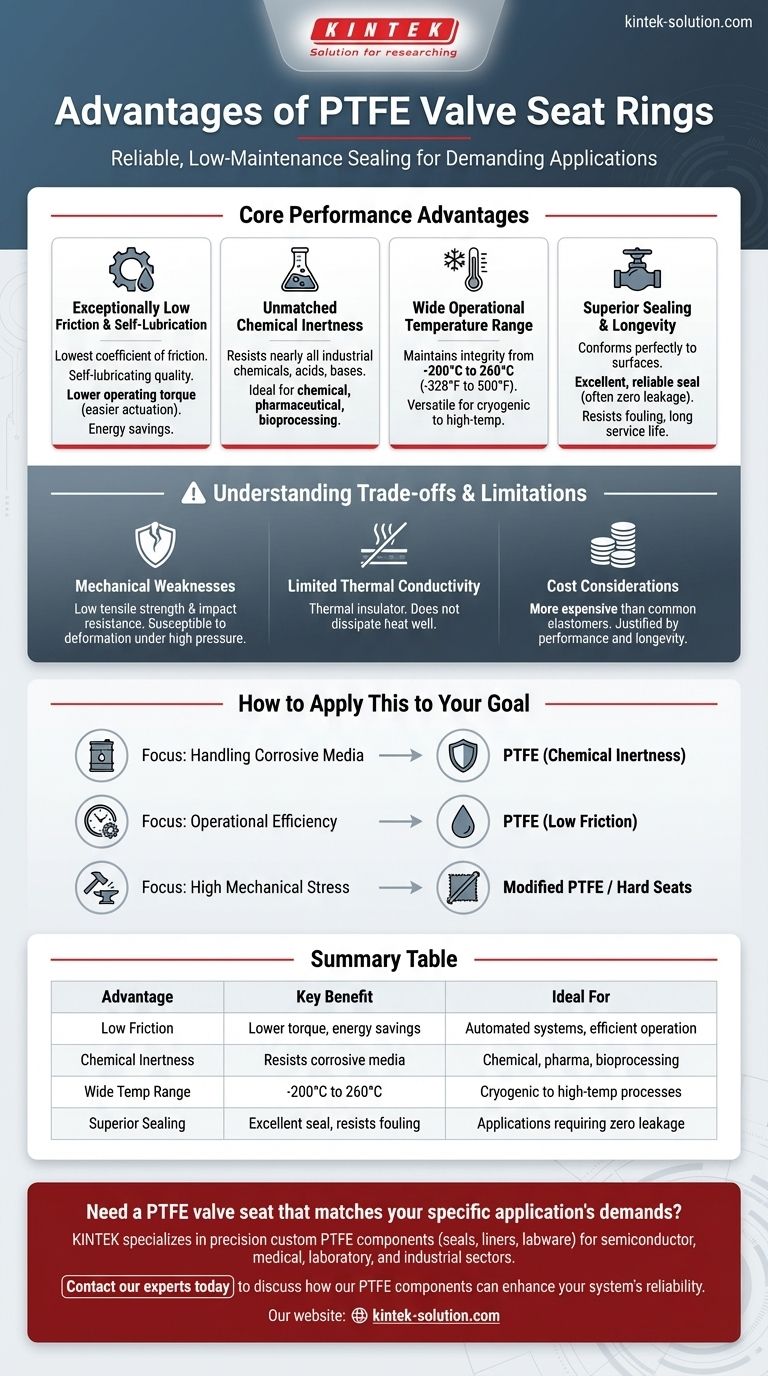

The Core Performance Advantages of PTFE Seats

The unique molecular structure of PTFE is directly responsible for its high-performance characteristics in industrial valves.

Exceptionally Low Friction and Self-Lubrication

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating quality is a significant operational advantage.

It directly translates to a lower operating torque, meaning the valve is easier to open and close. This reduces the energy required for actuation and can allow for smaller, more cost-effective actuators in automated systems.

Unmatched Chemical Inertness

PTFE is renowned for its chemical stability, resisting nearly all industrial chemicals, acids, and bases.

This makes it an ideal choice for applications in the chemical, pharmaceutical, and bioprocessing industries, where media is often highly corrosive. The valve seat can create a perfect seal without degrading, ensuring process purity and safety.

Wide Operational Temperature Range

PTFE maintains its integrity and performance across an exceptionally broad temperature spectrum, typically from -200°C to 260°C (-328°F to 500°F).

This versatility allows it to be specified for applications ranging from cryogenic services to high-temperature processing without requiring different seat materials.

Superior Sealing and Longevity

The inherent flexibility and non-stick nature of PTFE allow it to conform perfectly to the valve's sealing surfaces.

This results in an excellent and reliable seal, often achieving zero leakage. Because almost no substances adhere to its surface, it resists fouling and contamination, contributing to a long and predictable service life.

Understanding the Trade-offs and Limitations

While PTFE is a high-performance material, it is not universally applicable. An objective assessment requires acknowledging its limitations.

Mechanical Weaknesses

Virgin PTFE has relatively low tensile strength and impact resistance. It is a soft material susceptible to deformation under high pressure or damage from abrasive particles in the fluid stream.

For high-pressure applications or those with slurries, modified or filled grades of PTFE are often necessary to improve mechanical strength.

Limited Thermal Conductivity

PTFE is a thermal insulator, not a conductor. While it can withstand high temperatures, it does not dissipate heat well.

This is rarely a concern in typical valve applications but can be a factor in highly specialized designs where heat management is critical.

Cost Considerations

As a high-performance polymer, virgin PTFE is more expensive than many common sealing materials like rubber elastomers.

The higher initial cost is often justified by its longer service life, reduced maintenance needs, and superior performance in aggressive environments.

How to Apply This to Your Goal

Selecting the right valve seat is about matching the material's profile to the system's demands.

- If your primary focus is handling corrosive media: PTFE is an unparalleled choice due to its near-universal chemical inertness, ensuring system integrity and longevity.

- If your primary focus is operational efficiency and low maintenance: The self-lubricating, low-friction nature of PTFE reduces energy consumption and component wear over the valve's life.

- If your primary focus is applications with high mechanical stress or abrasion: You must consider modified PTFE grades or alternative hard-seated materials, as virgin PTFE lacks the necessary impact strength.

Ultimately, understanding both the exceptional strengths and the clear limitations of PTFE is the key to engineering a reliable and long-lasting valve system.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Low Friction | Lower operating torque, energy savings | Automated systems, efficient operation |

| Chemical Inertness | Resists nearly all corrosive media | Chemical, pharmaceutical, bioprocessing |

| Wide Temp Range | Performs from -200°C to 260°C | Cryogenic to high-temperature processes |

| Superior Sealing | Excellent seal, resists fouling | Applications requiring zero leakage |

Need a PTFE valve seat that matches your specific application's demands?

KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, and labware. Whether you require the unmatched chemical resistance of virgin PTFE or a modified grade for enhanced mechanical strength, our expertise ensures a perfect fit for your needs in the semiconductor, medical, laboratory, and industrial sectors.

We deliver high-performance solutions from prototypes to high-volume orders. Contact our experts today to discuss how our PTFE components can enhance your system's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why are PTFE seals suitable for high-velocity applications? Superior Performance at Extreme Speeds

- What are the primary functions of Teflon bushings? Achieve Maintenance-Free, Low-Friction Performance

- What is the overall function of PTFE bushes in mechanical systems? Achieve Low-Friction, Maintenance-Free Operation

- How do the non-stick properties of PTFE benefit sealing technology? Enhance Seal Life and Purity

- What are PTFE lined butterfly valves? A Guide to Corrosive Fluid Control

- How is PTFE used in sports rehabilitation and medical devices? Unlock Superior Biocompatibility and Performance

- What are the typical applications of PTFE bearing pads? Managing Movement in Bridges and Large Structures

- What are the friction characteristics of PTFE oil seals? Unlock Superior Performance with Low-Friction Seals