In any mechanical system, friction is the primary enemy of longevity and efficiency. PTFE bushes directly address this challenge by leveraging one of the lowest coefficients of friction of any solid material. This inherent slickness creates a self-lubricating surface that drastically reduces resistance, minimizing wear on moving parts and significantly extending their operational lifespan.

The core advantage of a PTFE bush is not simply its low friction, but how this property creates a self-sustaining system that reduces wear, minimizes energy loss, and lowers long-term maintenance requirements without external lubrication.

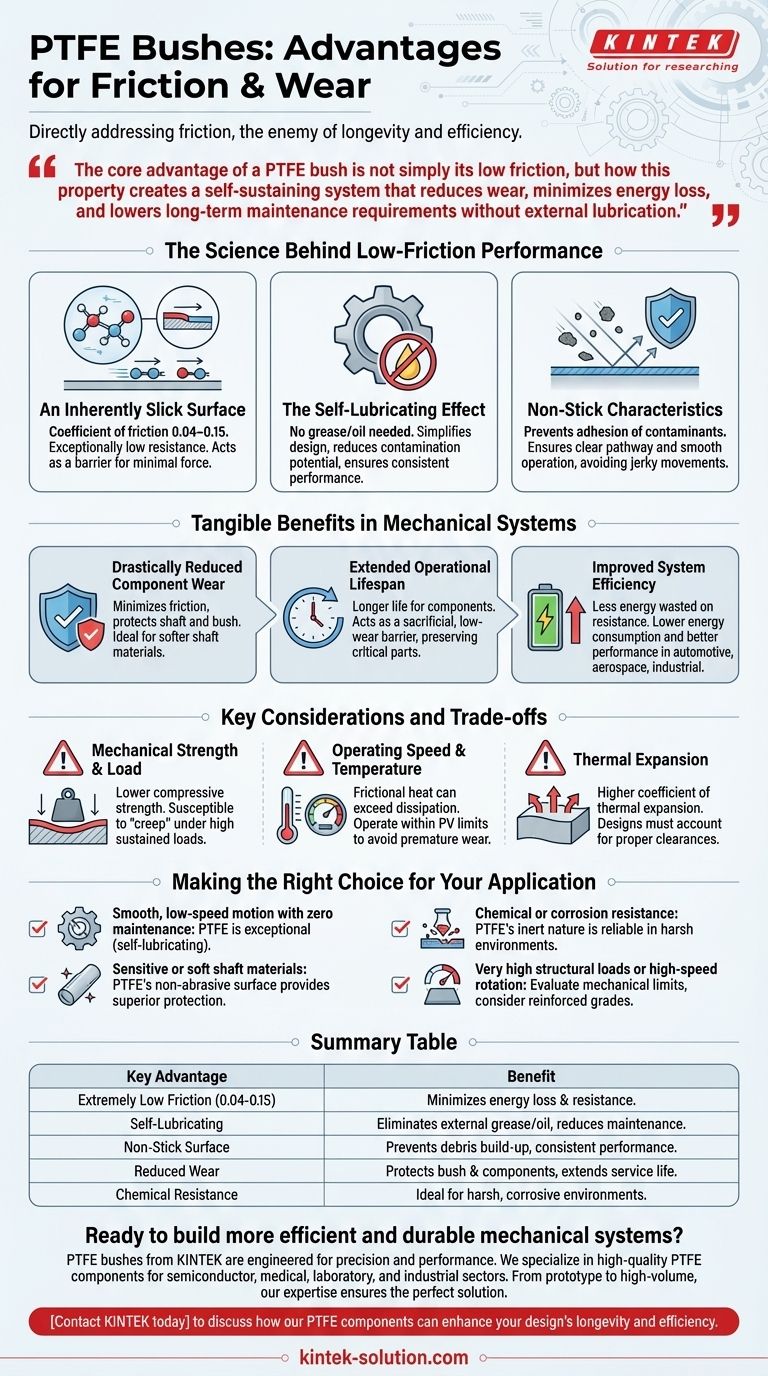

The Science Behind Low-Friction Performance

The unique molecular structure of Polytetrafluoroethylene (PTFE) is the source of its exceptional performance characteristics. Understanding these properties reveals why it is so effective in demanding applications.

An Inherently Slick Surface

PTFE has a coefficient of friction between 0.04 and 0.15, among the lowest recorded for any solid material. This means it creates exceptionally low resistance to movement.

The bush effectively acts as a barrier between two metal surfaces, allowing them to slide past each other with minimal force and abrasion.

The Self-Lubricating Effect

This extremely low friction means PTFE bushes are self-lubricating. They do not require grease or oil to operate smoothly in many applications.

This characteristic simplifies mechanical design, reduces the potential for contamination from external lubricants, and ensures consistent performance over the life of the component.

Non-Stick Characteristics

Beyond low friction, PTFE is also known for its non-stick surface. This property prevents other materials, contaminants, or debris from adhering to the bush.

In a dynamic system, this ensures that the pathway remains clear and operation stays smooth, avoiding the jerky movements that can arise from material build-up.

Tangible Benefits in Mechanical Systems

The scientific properties of PTFE translate directly into measurable improvements in reliability, efficiency, and cost-effectiveness for any system where it is deployed.

Drastically Reduced Component Wear

The primary benefit is a significant reduction in wear and tear. By minimizing friction, the PTFE bush protects both itself and the shaft it contacts from physical degradation.

This makes it an ideal choice for use with softer shaft materials that would be quickly damaged by more abrasive bearing types.

Extended Operational Lifespan

Reduced wear logically leads to a longer life for the components and the overall assembly.

By acting as a sacrificial, low-wear barrier, the PTFE bush preserves the integrity of more critical and expensive parts, extending service intervals and enhancing reliability.

Improved System Efficiency

Friction is a direct cause of energy loss in mechanical systems. Less friction means less energy is wasted overcoming resistance.

Using PTFE bushes can lead to more efficient operation, whether in automotive, aerospace, or industrial machinery, translating to lower energy consumption and better performance.

Key Considerations and Trade-offs

While PTFE's low-friction properties are exceptional, a technical advisor must also highlight its operational limits. Understanding these trade-offs is crucial for correct application.

Mechanical Strength and Load

Compared to metallic bearings, standard PTFE has lower compressive strength. It is best suited for low-to-moderate load applications.

Under very high sustained loads, PTFE can be susceptible to "creep" or cold flow, where the material slowly deforms over time.

Operating Speed and Temperature

While PTFE has a high temperature resistance, the combination of high rotational speeds and high loads can generate frictional heat faster than it can dissipate.

This can lead to premature wear, so designers must operate within the material's specified Pressure-Velocity (PV) limits.

Thermal Expansion

Like most polymers, PTFE has a higher coefficient of thermal expansion than metals. Engineering designs must account for this to maintain proper clearances across a range of operating temperatures.

Making the Right Choice for Your Application

The decision to use PTFE bushes should be guided by the specific performance demands of your system.

- If your primary focus is smooth, low-speed motion with zero maintenance: PTFE is an exceptional choice due to its inherent self-lubricating properties.

- If your system involves sensitive or soft shaft materials: PTFE's non-abrasive surface provides superior protection against wear compared to metal alternatives.

- If your application requires chemical or corrosion resistance: PTFE's inert nature makes it a highly reliable option for harsh operating environments.

- If your design involves very high structural loads or high-speed rotation: You must carefully evaluate PTFE's mechanical limits and consider reinforced PTFE grades or alternative materials.

By understanding both its unparalleled low-friction benefits and its material limitations, you can leverage PTFE to build more efficient and durable mechanical systems.

Summary Table:

| Key Advantage | Benefit |

|---|---|

| Extremely Low Friction (0.04-0.15 coefficient) | Minimizes energy loss and resistance for smoother operation. |

| Self-Lubricating | Eliminates need for external grease/oil, reducing maintenance and contamination. |

| Non-Stick Surface | Prevents debris build-up, ensuring consistent performance. |

| Reduced Wear | Protects both the bush and mating components, significantly extending service life. |

| Chemical Resistance | Ideal for harsh environments where other materials would corrode. |

Ready to build more efficient and durable mechanical systems?

PTFE bushes from KINTEK are engineered for precision and performance. We specialize in manufacturing high-quality PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

Whether you need a prototype or a high-volume order, our expertise in custom fabrication ensures you get the perfect solution for your application's specific friction, wear, and environmental challenges.

Contact KINTEK today to discuss how our PTFE components can enhance your design's longevity and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry